Harrington Hoists and Cranes (G)NTH Trolley User Manual

Page 23

23

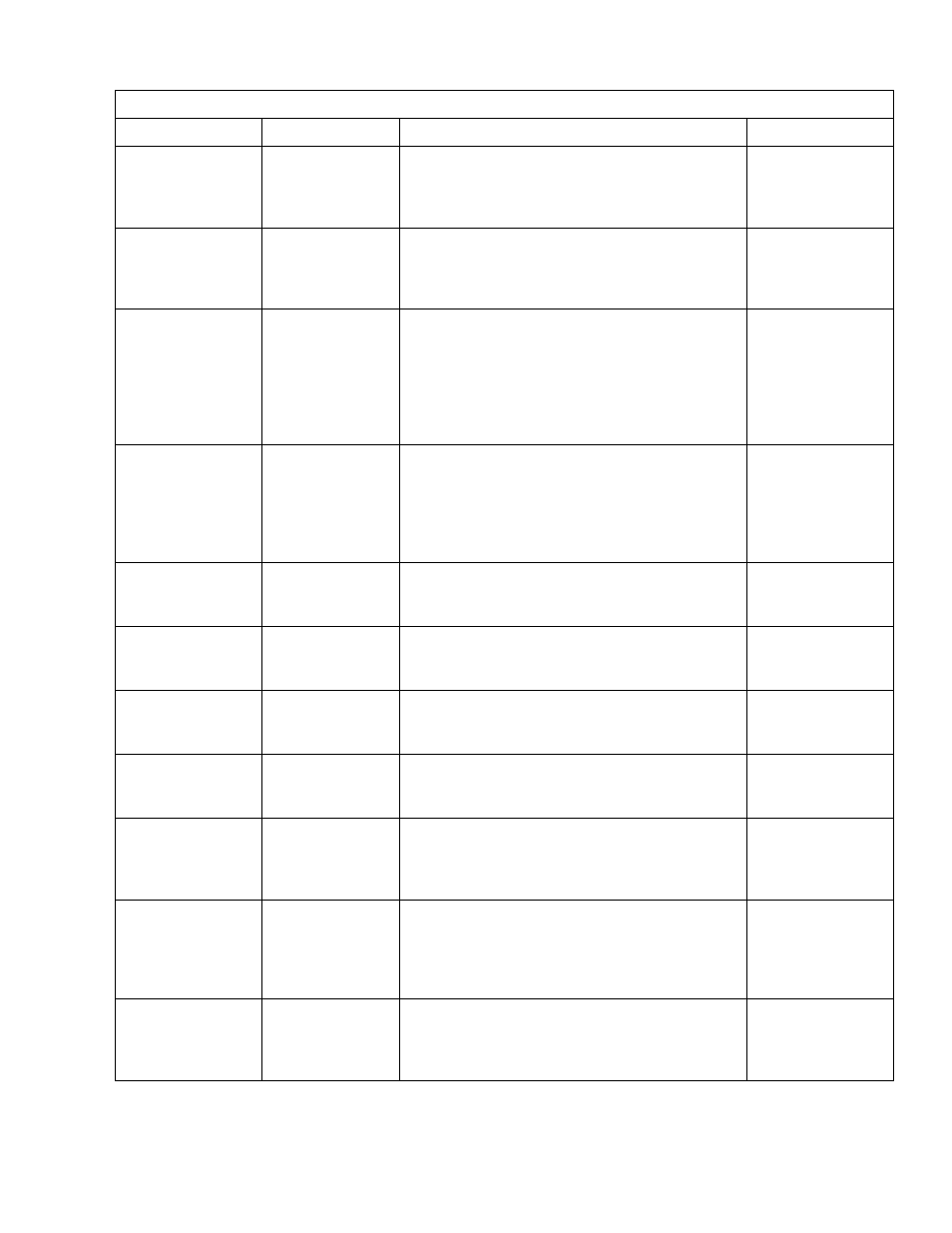

Table 5-3 Hoist Inspection Methods and Criteria

Item

Method

Discard Limit/Criteria

Action

Hook

– Swivel

Visual, Function

Bearing parts and surfaces should not show

significant wear, and should be free of dirt, grime,

and deformations. Hook should rotate freely with

no roughness. See Figure 5-1.

Clean/lubricate, or

replace as required.

Hook

– Yoke

Assembly

Visual

Should be free of significant rust, weld splatter,

nicks, and gouges. Holes should not be

elongated, fasteners should not be loose, and

there should be no gap between mating parts.

Tighten or replace

as required.

Hook

– Idle Sheave

and Shaft (Multiple

Fall Hoist)

Visual, Function

Pockets of Idle Sheave should be free of

significant wear. Idle Sheave surfaces should be

free of nicks, gouges, dirt, and grime. Bearing

parts and surfaces of Idle Sheave and Axle should

not show significant wear. Idle Sheave should

rotate freely with no roughness or significant free

play.

Clean/lubricate, or

replace as required.

Hook

– Hook

Latches

Visual, Function

Latch should not be deformed. Attachment of

latch to hook should not be loose. Latch spring

should not be missing and should not be weak.

Latch movement should not be stiff - when

depressed and released latch should snap smartly

to its closed position.

Replace.

Yoke

– Top Pin

Hole Deformation

Visual, Measure

The "d" dimension of the top pin hole should not

be greater than the discard value listed in Table 5-

5.

Replace Hook Set

Top Pin

–

Deformation

Visual, Measure

The pin should be free of scars or significant

deform

ation. The “d" dimension should not be

less than discard value listed in Table 5-6.

Replace

Yoke

– Chain Pin

Hole Deformation

Measure

The "d" dimension of the chain pin hole should not

be greater than the discard value listed in Table 5-

5.

Replace Hook Set

or yoke.

Chain Pin

–

Deformation

Visual, Measure

The pin should be free of scars or significant

deformation. The “d" dimension should not be

less than discard value listed in Table 5-7.

Replace

Load Chain

– Pitch

and Wire Diameter

Measure

The "P" dimension should not be greater than

discard value listed in Table 5-5. The "d"

dimension should not be less than discard value

listed in Table 5-8.

Replace. Inspect

Load Sheave (and

Idle Sheave for

multiple fall hoists).

Load Chain

–

Surface Condition

Visual

Should be free of gouges, nicks, dents, weld

splatter, and corrosion. Links should not be

deformed, and should not show signs of abrasion.

Surfaces where links bear on one another should

be free of significant wear.

Replace.

Load Chain

–

Lubrication

Visual, Auditory

Entire surface of each chain link should be coated

with lubricant and should be free of dirt and grime.

Chain should not emit cracking noise when

hoisting a load.

Clean/lubricate

(see Section 6.0).