Harrington Hoists and Cranes (G)NTH Trolley User Manual

Page 24

24

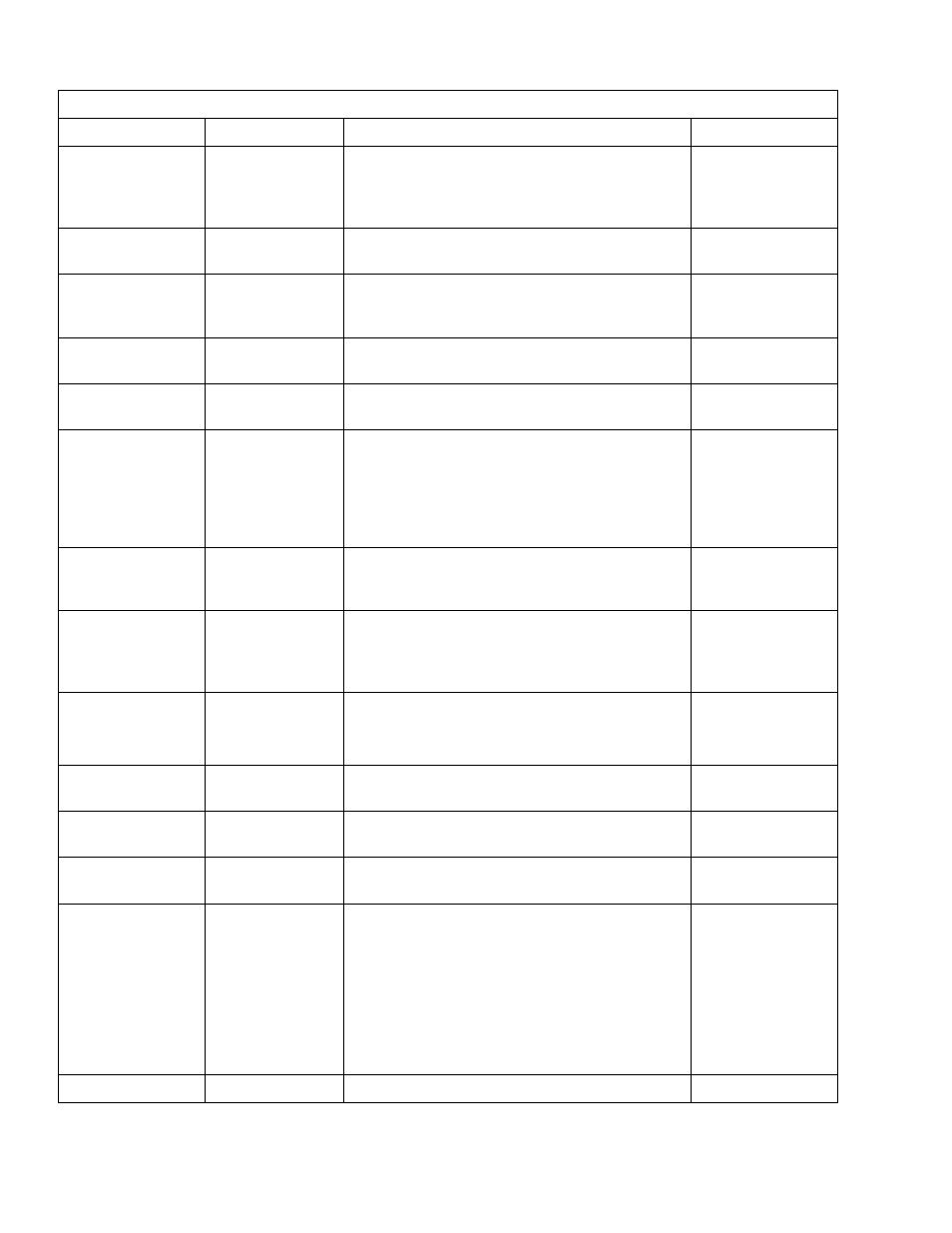

Table 5-3 Hoist Inspection Methods and Criteria

Item

Method

Discard Limit/Criteria

Action

Load Chain

–

Reeving

Visual

Chain should be reeved properly through Load

Sheave. On multiple fall hoists chain should be

installed properly and free of twists. Refer to

Section 3.2.

Reeve/Install chain

properly.

Lifting System

–

Components

Visual, Function

Components should not be deformed, scarred, or

show significant wear.

Replace.

Braking System

–

Components

Visual

Brake Pawl, Pawl Pin, and Pawl Spring should not

be deformed, scarred, or show significant wear.

Refer to Figure 5-2 (27, 24, & 26).

Replace.

Brake

– Damage to

Brake Surface

Visual

Damage due to scratching or gouging by foreign

matter. Refer to Figure 5-2 (32, 30, & 33).

Replace.

Braking System

–

Friction Disc

Visual

The surface of the friction plate should be free of

scars, gouges, and wear. Refer to Figure 5-2 (29).

Replace.

Braking System

–

Friction Plate

Visual, Measure

The surface of the friction plate should be free of

grease, oil, scars, gouges and wear and have

uniform thickness. The outer thickness should not

be thinner than the inner thickness. The thickness

should not be less than the discard value listed in

Table 5-9.

Replace.

Braking System

–

Bushing

Measure

The bushing should have uniform thickness. The

“t” dimension should not be less than the discard

value listed in Table 5-10.

Replace.

Braking System

–

Bushing

Visual

When slightly heated, the bushing should be so

lubricated that lubricant oozes off the surface.

Refer to Figure 5-2 (31). Type of oil to be used:

ISO VG68 or equivalent.

Soak bushing in

machine oil for one

day.

Braking System

–

Ratchet Disc

Measure

The “D” dimension should not be less than the

discard value listed in Table 5-11.

Refer to Figure 5-2 (30).

Replace.

Load Sheave

Visual

Pockets of Load Sheave should be clean and free

of significant wear. Refer to Figure 5-3 (18).

Replace.

Load Gear

Visual

Teeth have excessive wear or damage. Refer to

Figure 5-4 (19).

Replace.

Hand Wheel

Visual

Large wear or deformation on the surface of hand

wheel. The hand wheel touches the cover.

Replace.

Housing and

Mechanical

Components

Visual, Auditory,

Function

Trolley-hoist components including suspension

shafts, track wheels, track wheel axles, load

blocks, suspension housing, chain attachments,

clevises, yokes, suspension bolts, shafts, gears,

bearings, stripper, pins, rollers, and bumpers

should be free of cracks, distortion, significant

wear, and corrosion. Evidence of same can be

detected visually or via detection of unusual

sounds during operation.

Replace.

Chain Guide

Visual

Excessive wear or press mark.

Replace.