Harrington Hoists and Cranes TNER Theater Hoist User Manual

Page 27

6.1.3

Gear Box:

Using an incorrect type/grade of gearbox grease or the wrong quantity of grease

may prevent the friction clutch from working properly and may affect the ability of the hoist to hold the

load. Refer to Section 3.1 for the correct grease and quantity.

If experiencing abnormal noise or unusual gearbox operation, have the gearbox serviced by a qualified

individual.

Always replace the gearbox grease when servicing the gearbox.

Dispose of the used grease in accordance with local regulations.

6.2

Motor Brake

6.2.1

To keep your hoist working in optimum condition and prevent possible down time, it is recommended to

check your motor brake lining and adjustment at regular intervals.

6.2.2

Motor Brake Unit Removal - Adjustment and inspection of the motor brake requires removal of the motor

brake unit from the hoist as an assembly.

1)

Before proceeding disconnect the power supply and make sure the hoist is unloaded.

To keep the load chain from moving secure it by tying together the load and no-load sides directly under the

hoist using a cord or wire.

2)

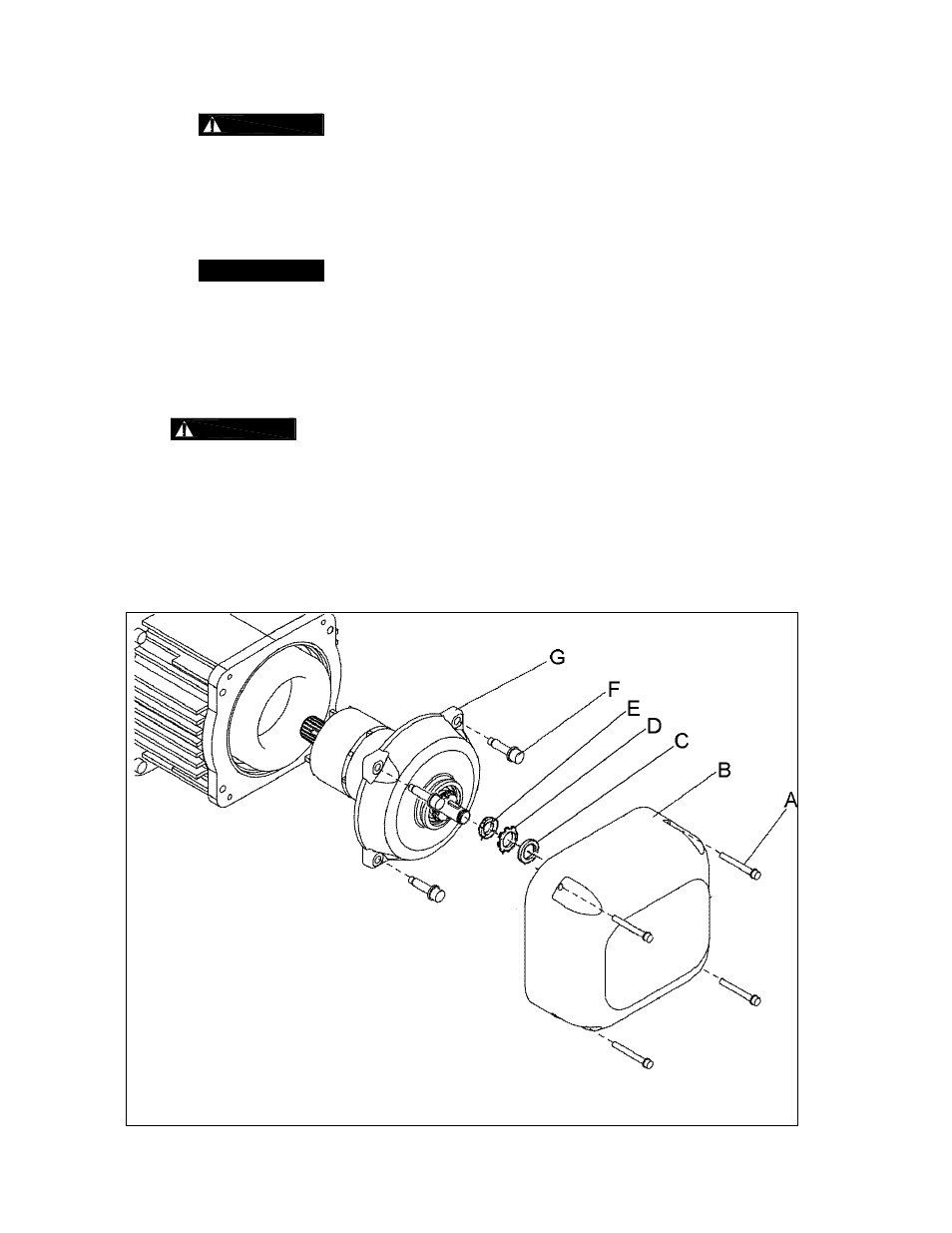

Refer to Figure 6-3.

3)

Remove the four Frame Cover Bolts (A), Frame Cover (B), Nut (C), Lock Washer (D), and Spacer (E).

4)

Remove the four Motor Cover Assembly bolts (F) and carefully pull the motor brake unit (G) out of the hoist.

Figure 6-2 Motor Brake

27