Harrington Hoists and Cranes TNER Theater Hoist User Manual

Page 23

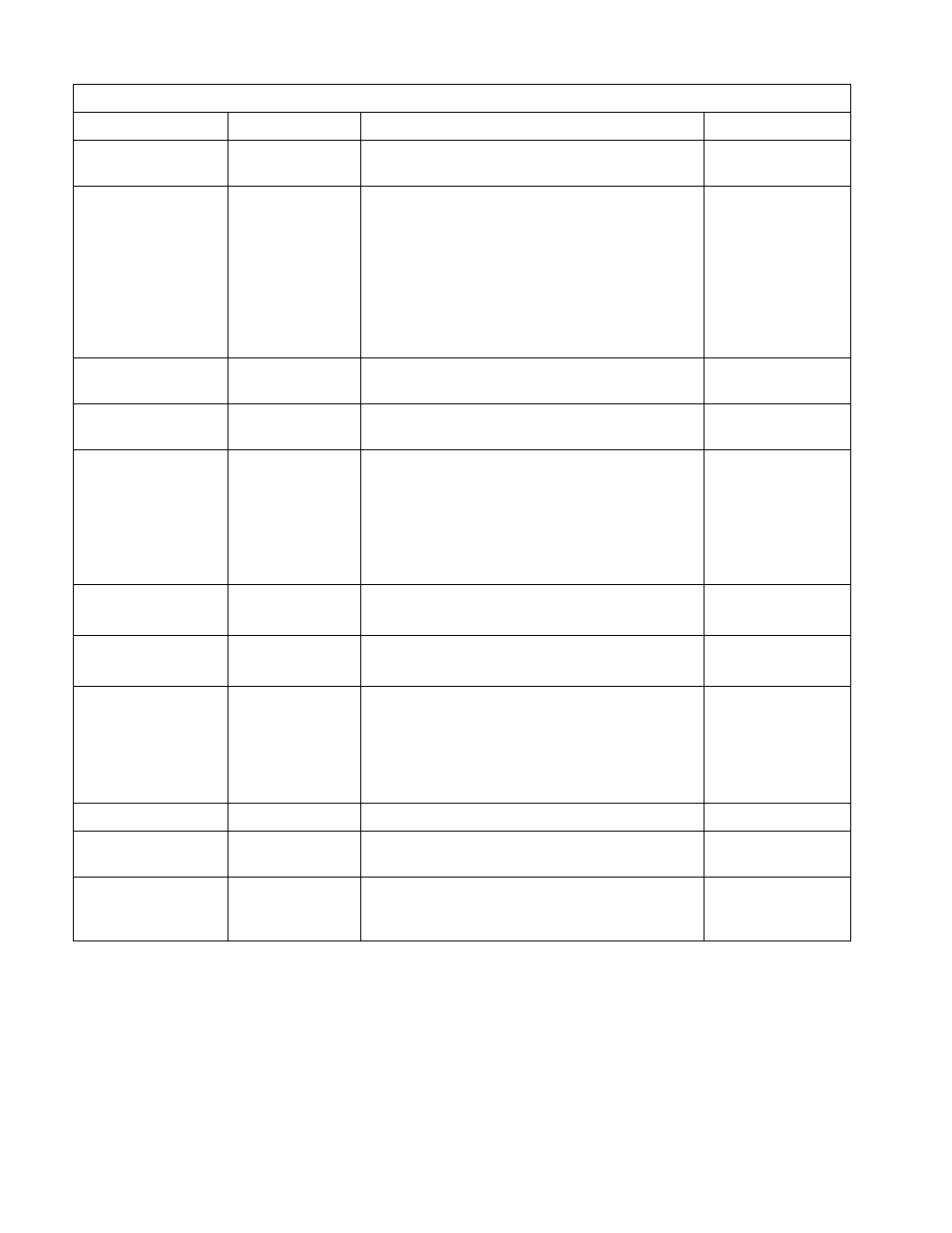

Table 5-3 Hoist Inspection Methods and Criteria

Item

Method

Criteria

Action

Bolts, Nuts and

Rivets

Visual, Check

with Proper Tool

Bolts, nuts and rivets should not be loose.

Tighten or replace

as required.

Motor Brake

Measure, Visual

Motor brake gap should be adjusted to the

distance shown in Table 6-1 before measuring

the brake wear. Brake lining dimension “A”

should not be less than discard value listed in

Table 5-6. Refer to Section 6.2 for gaining

access to motor brake and for adjustment and

inspection procedures. Braking surfaces should

be clean, free of grease/oil and should not be

glazed.

Adjust, Repair or

Replace as

required.

Contactor Contacts

Visual

Contacts should be free of significant pitting or

deterioration.

Replace.

Load Sheave

Visual

Pockets of Load Sheave should be free of

significant wear.

Replace.

Pendant – Switches

(Optional)

Function

Depressing and releasing push-buttons should

make and break contacts in switch contact block

and result in corresponding electrical continuity or

open circuit. Push-buttons should be interlocked

either mechanically or electrically to prevent

simultaneous energization of circuits for opposing

motions (e.g. up and down).

Repair or replace

as necessary.

Pendant - Housing

(Optional)

Visual

Pendant housing should be free of cracks and

mating surfaces of parts should seal without gaps.

Replace.

Pendant - Wiring

(Optional)

Visual

Wire connections to switches in pendant should

not be loose or damaged.

Tighten or repair

Pendant - Cord

Visual, Electrical

Continuity

Surface of cord should be free from nicks,

gouges, and abrasions. Each conductor in cord

should have 100% electrical continuity even when

cord is flexed back-and-forth. Pendant Cord

Strain Relief Cable should absorb all of the load

associated with forces applied to the pendant.

Replace.

Pendant - Labels

Visual

Labels denoting functions should be legible.

Replace.

Warning Labels

Visual

Warning Labels should be affixed to the hoist (see

Section 1.2) and they should be legible.

Replace.

Hoist Capacity Label Visual

The label that indicates the capacity of the hoist

should be legible and securely attached to the

hoist.

Replace.

23