Troubleshooting guide (cont.) – Ransburg PulseTrack2 A11515-XXXXX User Manual

Page 46

(Continued On Next Page)

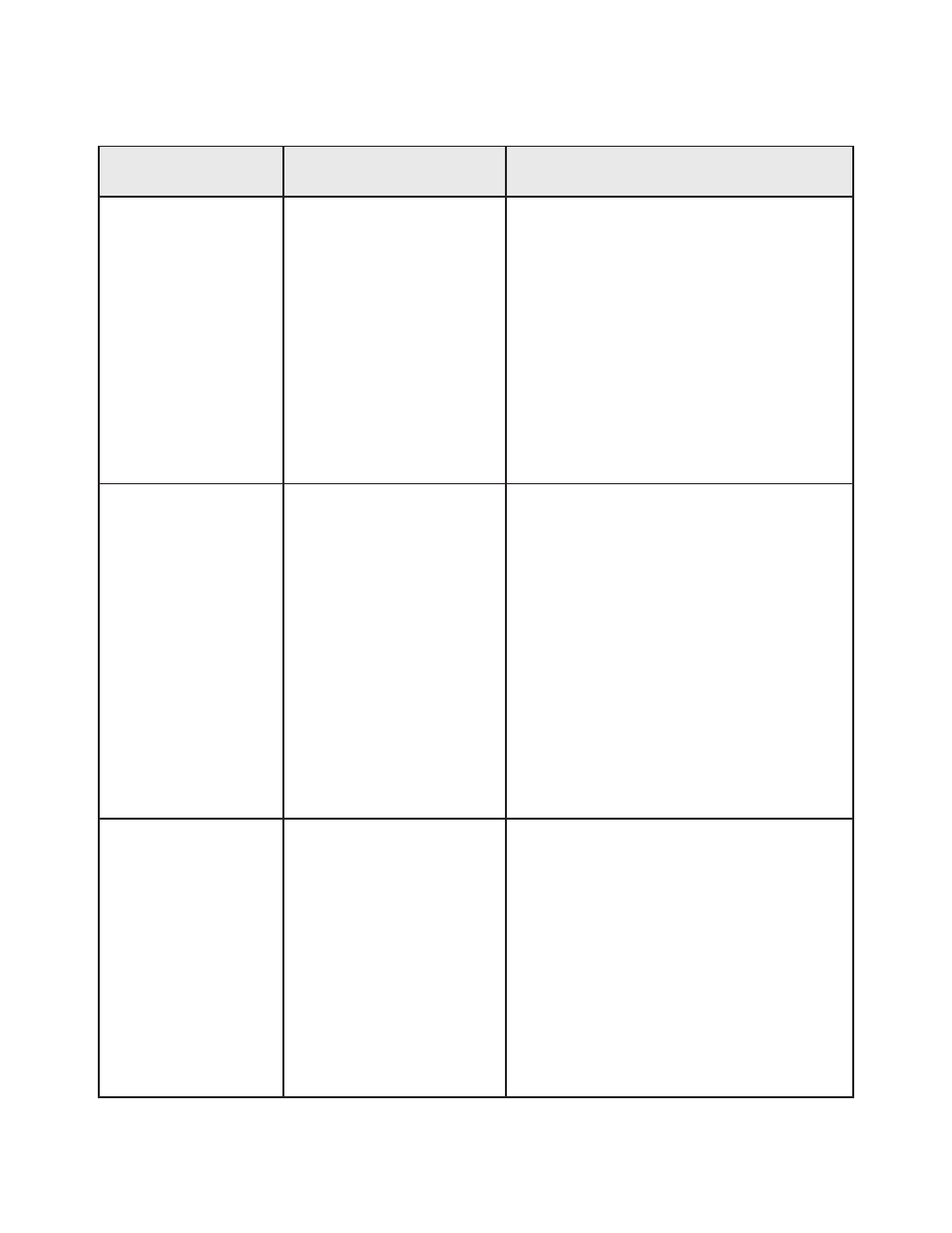

TROUBLESHOOTING GUIDE (Cont.)

General Problem

Procedure

Solution

UNDERSPEED

Fault (uS) (Cont.)

OVERSPEED

Fault (oS)

LOSS OF FEEDBACK

Fault (LF)

3. Improper rotator type DIP

switch setting on Atomizer

Card

4. Failing rotator or restricted

drive air

5. Defective Current to Pres-

sure Transducer

1. Defective brake solenoid

or brake valve assembly

tubing connection or com-

ponent (bells)

2. Improper rotator type DIP

switch setting on Atomizer

Card

3. Defective Current to Pres-

sure Transducer

1. No supply air to rotator or

control panel

2. Current to Pressure Trans-

ducer output (CL1-CL6)

disconnected or broken

3. Verify that the proper rotator type is selected

on the Atomizer Card DIP switches (see

Table 7).

4. Observe the Current to Pressure Transducer

output pilot pressure. If the pressure climbs

higher than normal or is maximum for an

extended period of time, then the drive air

signal to the rotator is restricted or the rotator

is failing.

5. If the Current to Pressure Transducer out-

put pressure is zero or lower than normal,

replace it.

1. Verify connection and operation of the brake

solenoid and valve assembly. Replace as

necessary.

2. Verify that the proper rotator type is selected

on the Atomizer Card DIP switches (see

Table 7).

3. Observe the Current to Pressure (I/P) Trans-

ducer output pilot pressure. If the pressure

is higher than normal or does not decline,

then replace the I/P Transducer. If the I/P

Transducer appears to be operating correct-

ly, then replace the 1:1 air piloted regulator.

1. Verify that supply air to the Control Panel

and air regulator assemblies is correct and

stable.

2. Connect or repair.