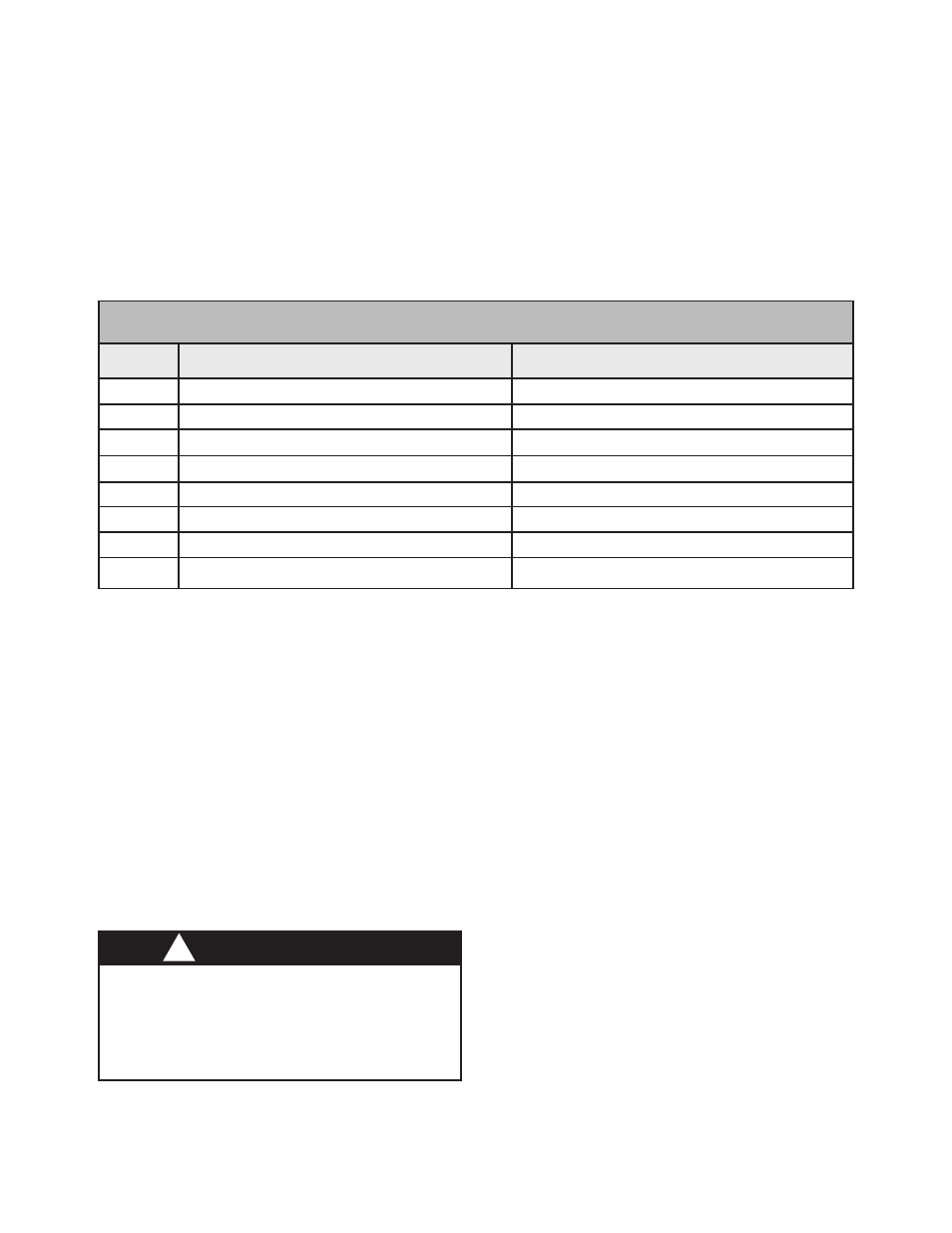

Table 6 - control card sw1 dip switch settings, Atomizer card – Ransburg PulseTrack2 A11515-XXXXX User Manual

Page 29

Dip Switch SW1-7

This dip switch is used in conjunction with board

jumpers E1-E6 to set the mode of the analog

speed outputs. This is described previously in

this section under Analog Speed Outputs and is

detailed in Table 4. This switch is factory set to

the OFF position.

TABLE 6 - CONTROL CARD SW1 DIP SWITCH SETTINGS

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

Position

ON

OFF

Brake air not applied when bell turned off

Not Used - Leave set to OFF

Not Used - Leave set to OFF

Not Used - Leave set to OFF

Not Used - Leave set to OFF

0-10VDC Analog speed setpoint inputs

0-10VDC Analog speed outputs

DO NOT TURN OFF

Brake air applied when bell turned off

N/A

N/A

N/A

N/A

4-20mA Analog speed setpoint inputs

4-20mA Analog speed outputs

4-20mA Transducer input

Atomizer Card

There is a 4 position dip switch SW2 located near

the bottom of each atomizer card (see Figure 11).

These dip switches set the board for use with the

desired rotator and are factory set according to

the PulseTrack 2 ordering configuration (see Table

7). The control card reads these dip switches and

adjusts the PID control to the optimum settings for

the rotator in use. These settings also determine

the maximum speed for the rotator in use. If it

becomes necessary to change these settings do

to a change in rotator type, perform the following:

>

Use the proper setting for the rotator in

use. Use of the incorrect setting can result

in higher rotator speeds than design per-

mits. This can lead to rotator failure causing

property damage and/or personal injury.

W A R N I N G

!

1. Turn AC power off and access the interior of

the cabinet.

2. Change the desired dip switch settings.

3. Secure the cabinet door and turn AC power

back on.

Dip Switch SW1-8

This dip switch sets the current to pressure (IP)

transducer input mode for 4-20mA. It should

always be in the ON position. It is not possible

to run the transducers in 0-10VDC input mode.