Turbine test, Bearing air / drive air test, N o t e – Ransburg Test Stand RMA-303, EVOLVER, EVOLVER NE User Manual

Page 18: Brake test

LN-9259-07.1

Bearing Air / Drive Air Test

This test is to verify the applicator responds to

changes in setpoints in the speed selector.

1. Raise the safety spin guard and lock it in place

with the pin.

N O T E

> Bell cup and shroud must be attached

to end of turbine.

TURBINE TEST

The purpose of this test is to verify the applica-

tor rotates properly and sprays reasonably well.

With de-ionized or distilled water as the test fluid

it is difficult to accurately assess the spray per-

formance characteristics. However, it can give a

relative indication of how well the bell will spray

in production.

Test Stations - Operation

15

2. Adjust the air regulator for bearing air to 90

psig minimum.

3. The turbine shaft must rotate freely with bear-

ing air supplied.

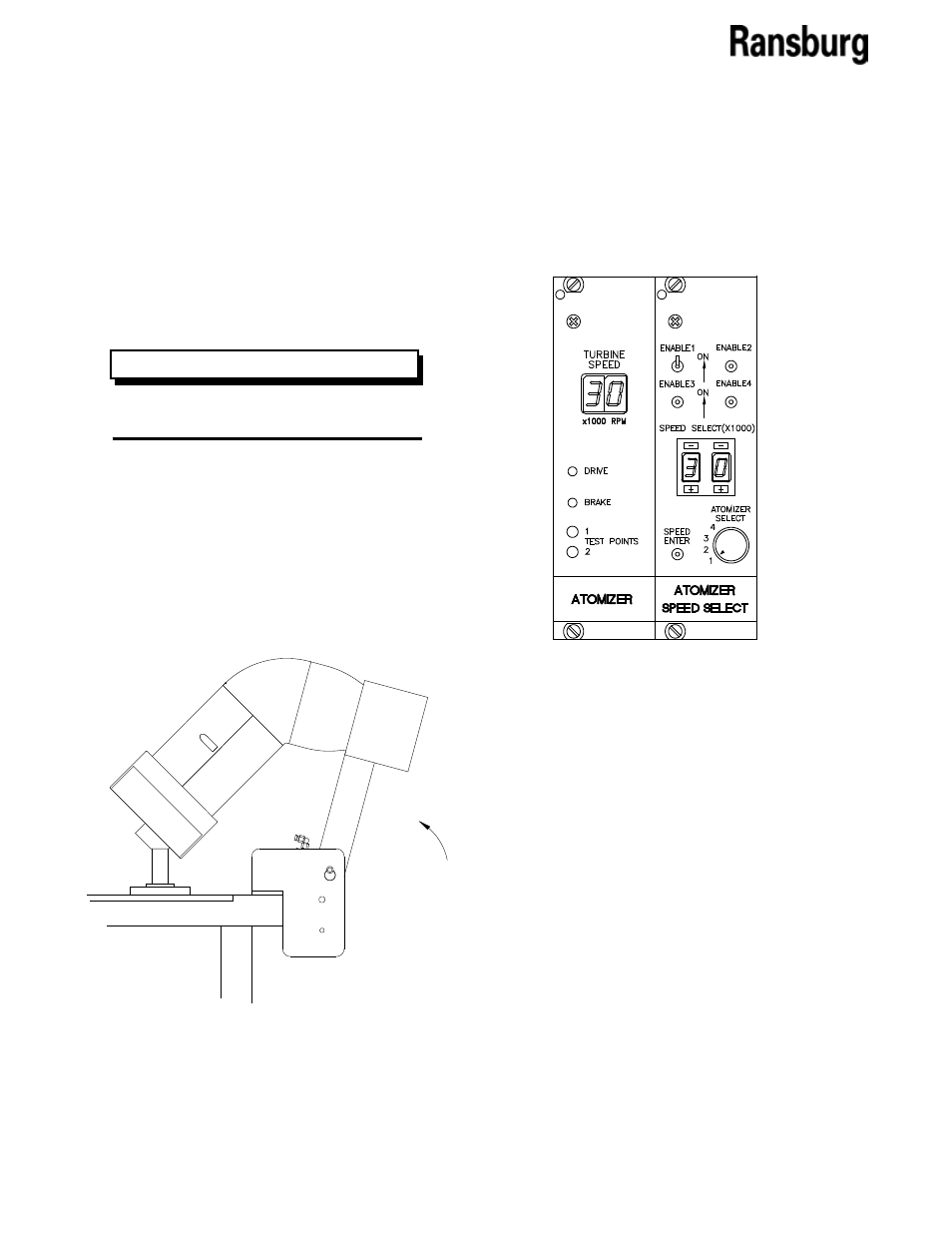

4. Set the atomizer speed select to 30,000 rpm.

5. Toggle “Enable 1” “On” or in the “Up” position

on the atomizer speed select card. Then press

the “Speed Enter” button. The turbine should now

begin spinning. This should be audible.

6. Adjust the speed select to 50,000 rpm. Press

the “Speed Enter” button to enter the new speed.

An audible difference in speed should be de-

tected. Adjust the speed again to 70,000 rpm

and press “Speed Enter” to enter the new speed.

7. Observe the atomizing air gauge. At 70,000

rpm the air consumption should not exceed 17.0

SCFM.

Brake Test

1. Re-adjust the turbine speed select card to

70k rpm.

2. Set the atomizer speed card to 1k rpm. (Do not

activate this speed until the next step.)

3. Using a stop watch to time the brake speed,

press the atomizer speed card button and watch

the time it takes for the applicator to reach 1k rpm.

4. Brake time should NOT exceed 14 seconds.