Ransburg Test Stand RMA-303, EVOLVER, EVOLVER NE User Manual

Page 17

LN-9259-07.1

Test Stations - Operation

14

10. Activate the “dump” trigger until the air is

completely purged from the manifold. You will see

water running from the dump output. Turn the

“Dump” switch off which will stop the water flow.

Turn “Fluid” switch to “off”. Leak gauge should

stay at pressure.

11. Observe the applicator for any possible water

leakage, wait 3 minutes. No seepage is allowed.

12. If leak is found, turn the “Fluid” switch to “Air”

and activate the dump until all water is evacu-

ated. Turn “Fluid” switch to “Off”. Repair leak

and repeat the test.

13. If no leak is found, turn the “Fluid” switch to

“Air”. Open the dump to purge out the water.

14. When all water has been evacuated, close

the dump, turn off all switches and turn the “Fluid”

switch to “Off”.

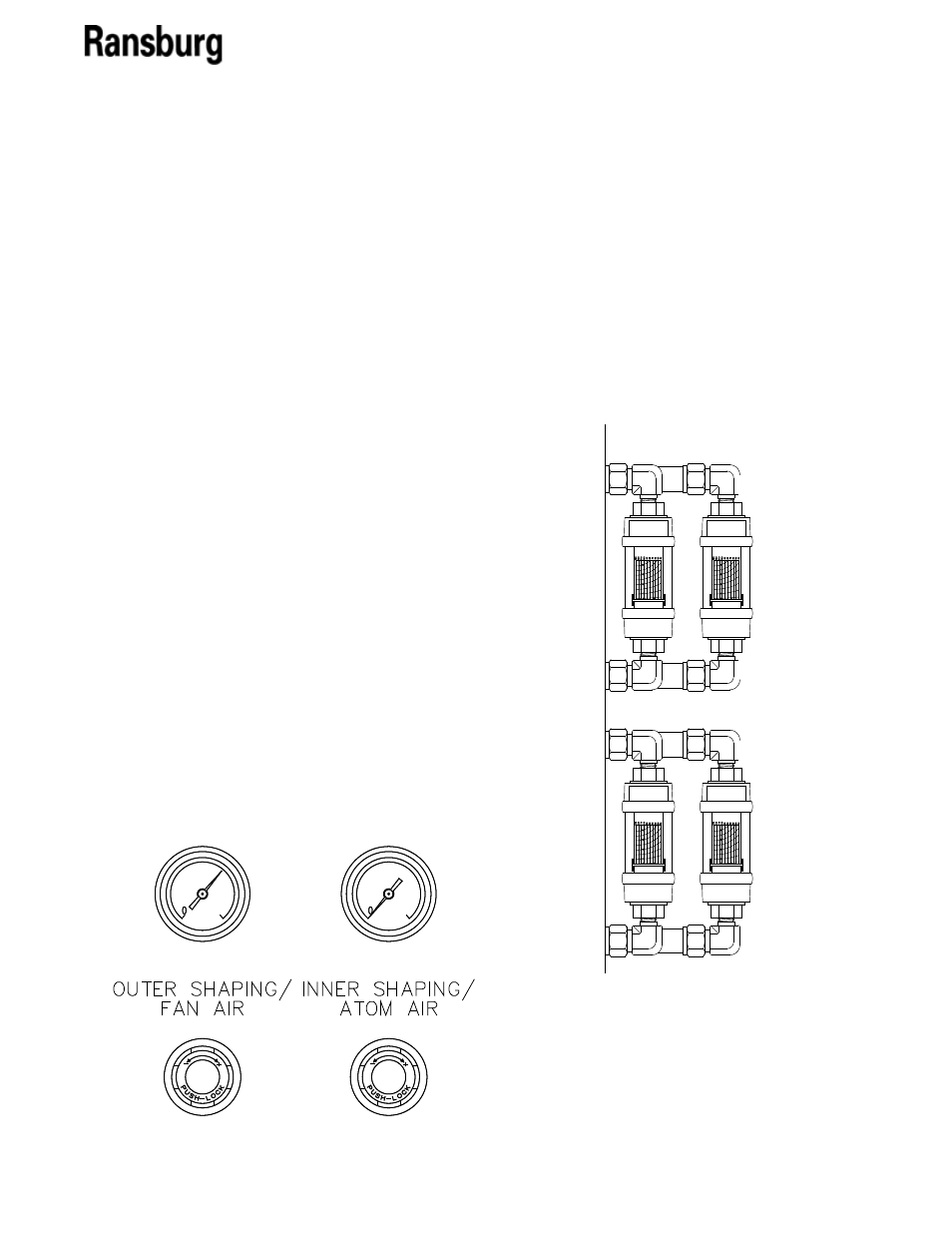

Shaping Air Consumption Test (Inner and

Outer)

1. Reduce the turbine speed from 70k to 30k rpm.

2. Turn on the “Shaping Air” dial and adjust the

outer shaping air to 60 psi. Reference the shaping

air gauge for the correct pressure reading. Ensure

no air leak is present between the shaping air cap

and shroud. If present, inspect the assembly.

3. Look at the shaping air flow meter. It should

be reading 10-13 CFM (outer) and 10-13 CFM

(inner). Make sure the flow meter regulator is

100

100

100

100

adjusted to 100 psi input pressure.

4. Readjust the shaping air dial to 25 psi. Refer-

ence shaping air gauge for the correct pressure

reading.

5. Look at the shaping air flow meter. It should

be reading 4-7 CFM (outer) and 4-7 CFM (inner).

Make sure the flow meter regulator is adjusted to

100 psi input pressure.

6. Turn off the “Shaping Air” dial.

TURBINE

S.A.O./FAN

S.A.I./ATOM

BEARING AIR