Compressor connections – Kasco Marine Robust-Aire User Manual

Page 4

4

off at shore before connecting to the compressor lead.

10. Tie off shore end of the SureSink™ Tubing by the com-

pressor cabinet. Make sure you have a few extra feet

of tubing to work with so that the tube will reach the

cabinet after trenching the tube between the shore and

the compressor.

11. Assembled Diffuser(s) can be loaded onto the boat.

Possible additional tubing kits and assembly tools

should be loaded on the boat if not already connected.

12. Make sure the boat is in reverse to avoid damaging the

boat prop and slowly make your way to the marking

buoy pulling the tubing as you go.

13. Once you reach the marked buoy, thread a rope through

the two slots of the diffuser base. Pull through until the

rope is at the midway point by the diffuser base.

14. While holding the two ends of the rope, gently lower

the diffuser assembly into the water. Submerge the

assembly and allow the air to escape from the vent plug

as the base fills with water.

15. When the air has been removed from the base, con-

tinue lowering the assembly slowly until it reaches the

bottom of the pond. Using this method, the diffuser

should not invert while lowering.

16. Pull up on only one side of the rope to bring it back.

The Robust-Aire

®

Diffuser should now be seated

properly on the bottom of the pond. (Optional: For

ease of future maintenance, it is recommended to leave

rope looped through diffuser base and tie both ends to

marker-buoy or duck decoy. This will allow diffusers to

be located easily and pulled up for maintenance.)

17. Repeat the process for additional Robust-Aire

®

Diffuser

locations.

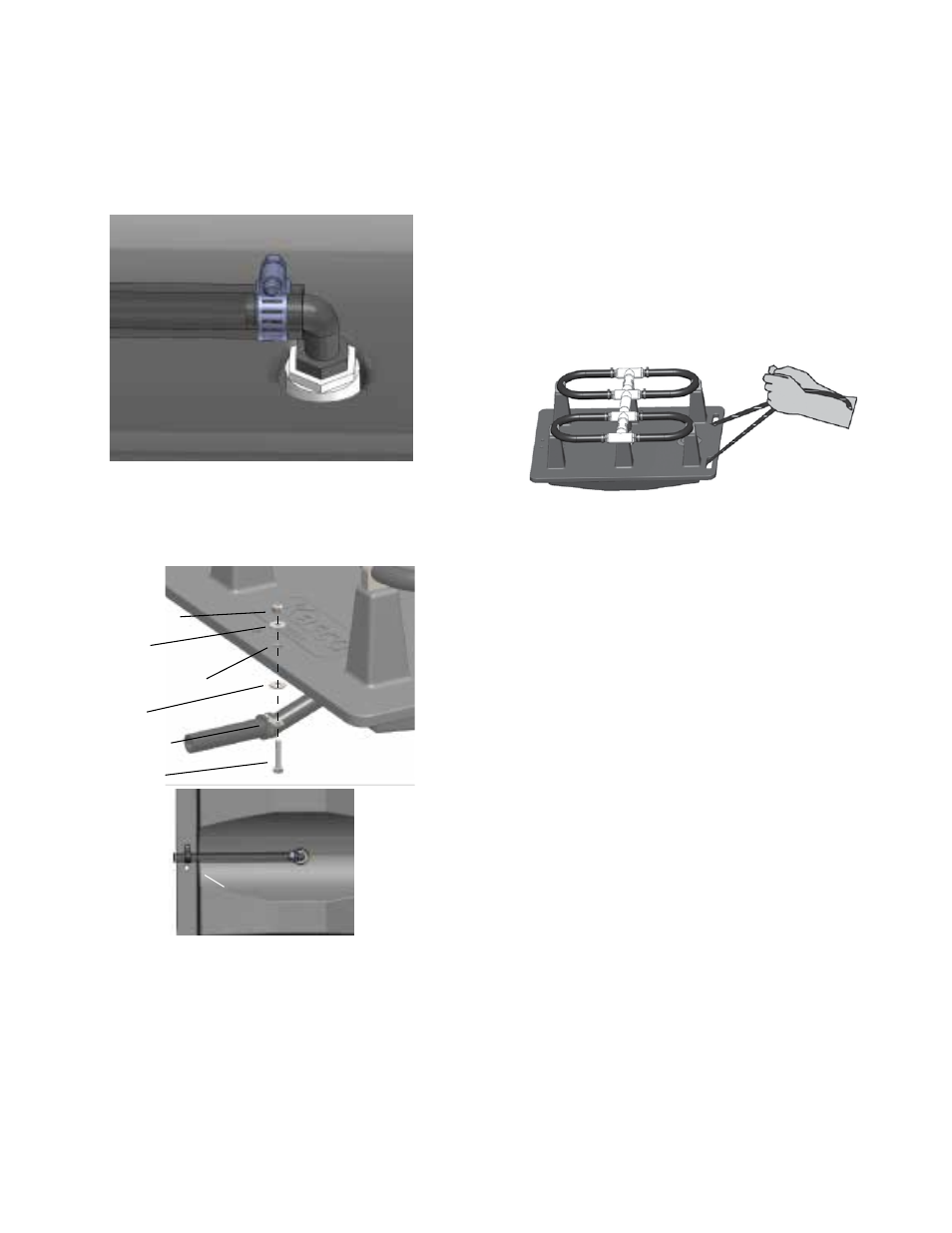

Compressor Connections

18. When back on shore, finish connecting the tubing

to the lead hose from the compressor with the

supplied barb fitting from the tubing kit. Secure

and tighten clamps to both supply tubing and

compressor hose.

decrease if the tube is not properly uncoiled.

7. On the end of the SureSink™ Tube that will be con-

nected to the diffuser assembly, slide a clamp over the

tubing and connect the end of the tubing to the barbed

fitting on the diffuser assembly. Position clamp over

tubing and barbed fitting and tighten using a 5/16”

socket driver or screwdriver. Do not over tighten

clamp.

Bottom of Diffuser Assembly

SureSink

™

tubing

Clamp

1/2” NPT X

3/8” or 5/8”

Elbow

8. Install strain relief over tubing and secure to diffuser

base as shown using 7/16” socket and wrench. A prop-

erly installed strain relief will prevent any damage to

the diffuser assembly when it is lowered in the water or

pulled up at a later date for maintenance.

1/4” lock nut

washer

Diffuser Base hole

washer

strain relief

1/4” screw

Strain relief

9. If you anticipate running out of tubing (each tube is

100’) before reaching the buoy, connect any additional

tubes according to the SureSink™ Tube instructions.

Make sure to unroll these tubes as you did with the first

tube. If you are unsure how many rolls of tubes will be

needed to reach the diffuser location, you can load the

unconnected diffuser assemblies and tubing kits into

the boat and connect as needed while making your way

to the marked buoy. You can also connect an ample

number of 100’ lengths together and have someone as-

sist feeding it from shore. The excess tubing can be cut