Darex XT-3000A User Manual

Page 60

58

Material Take off Adjustment for SA16401TA (1.5-7mm Chuck):

Calibrating the Material Removal Knob

Mini Attachment

LEX350 & LEX351

Small diameter bits have a high possibility of

breaking if too much pressure is put on them.

For this reason, it is critical to follow all of the

safety warnings in the XT 3000 User’s

Manual. In particular, it is very important to

wear ANSI certified (impact resistant) goggles

when sharpening small bits!

To minimize the risk of breaking bits, burning

them because of too much material take off,

or creating negative relief on the small bit,

the Small Chuck is designed to have a very

small Material Take Off (MTO). It will operate

only at the high end of the Material Take Off

(MTO) adjustment range.

This minimizes

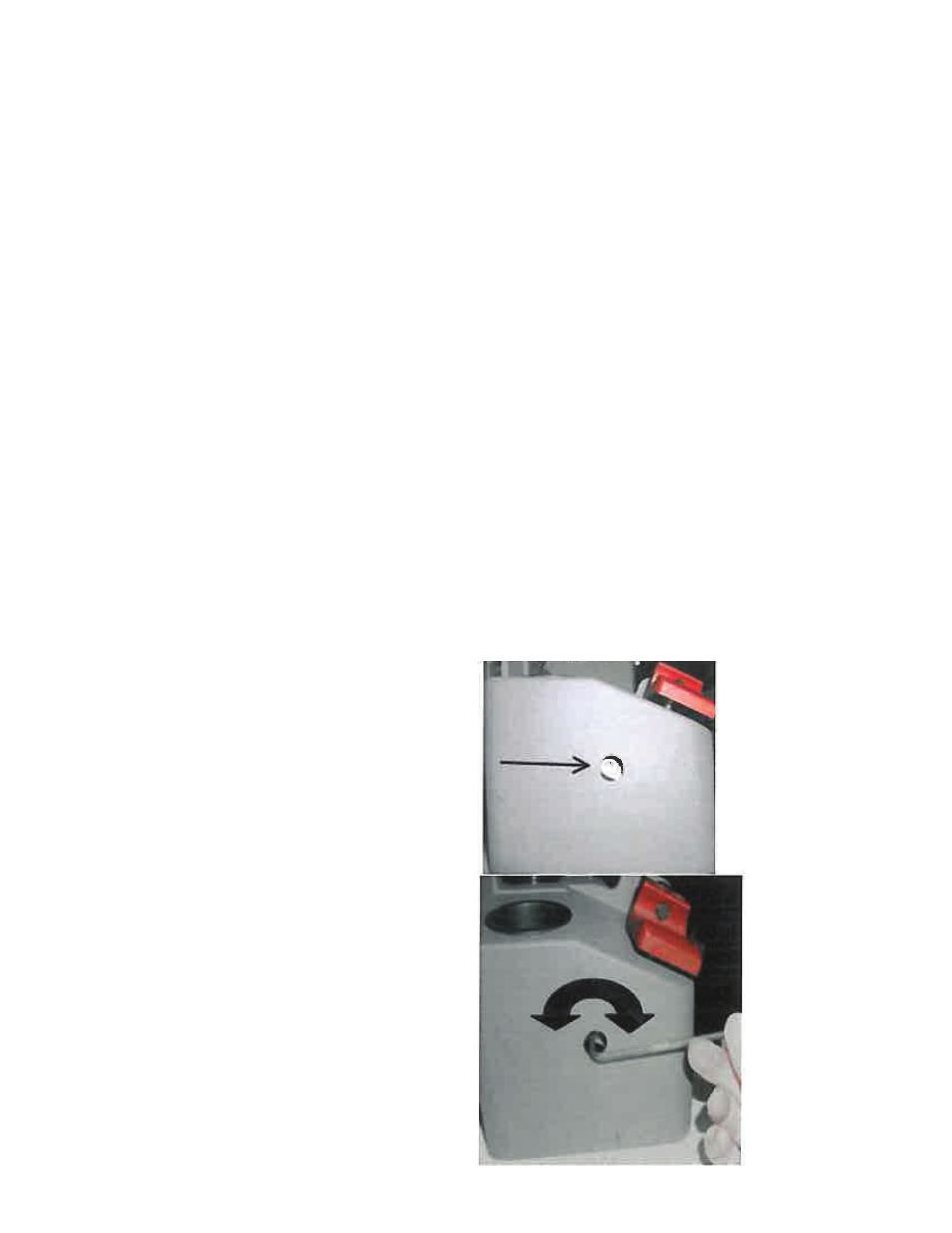

1. At the rear of the machine base, there is

a small access hole.

2. Insert a 5/32 Allen wrench into the

access hole.

3. To retract the pusher shaft cap, increas-

ing the amount of drill stick out, rotate

the wrench counterclockwise.

4. Each 1/4 turn will adjust 0.010”

(0,25mm) or one full turn will adjust

0.040” (1,0mm). After adjusting the

pusher shaft assembly, realign the drill

and remeasure the amount of stick out.

Repeate steps 2-4 until the system

removes approximately 0.005” (0,12mm)

of material from the small drill.

the possibility of a user accidentally trying

to remove 0.015” or 0.025” of material and

ruining a

small bit. Because the chuck has

been tuned for low MTO, it is possible that

your XT3000 may be adjusted out of working

range. If a drill bit mounted in the Small

Chuck, and then aligned at maximum MTO

(meaning the MTO knob is fully

counter-clockwise) does not touch the grinding

wheel, then you will need to adjust the

Material Removal knob to allow additional

material take off. Simply follow the instructions

from page 23 of the User’s Manual, which are

partly re-printed below.