Darex XT-3000A User Manual

Page 57

55

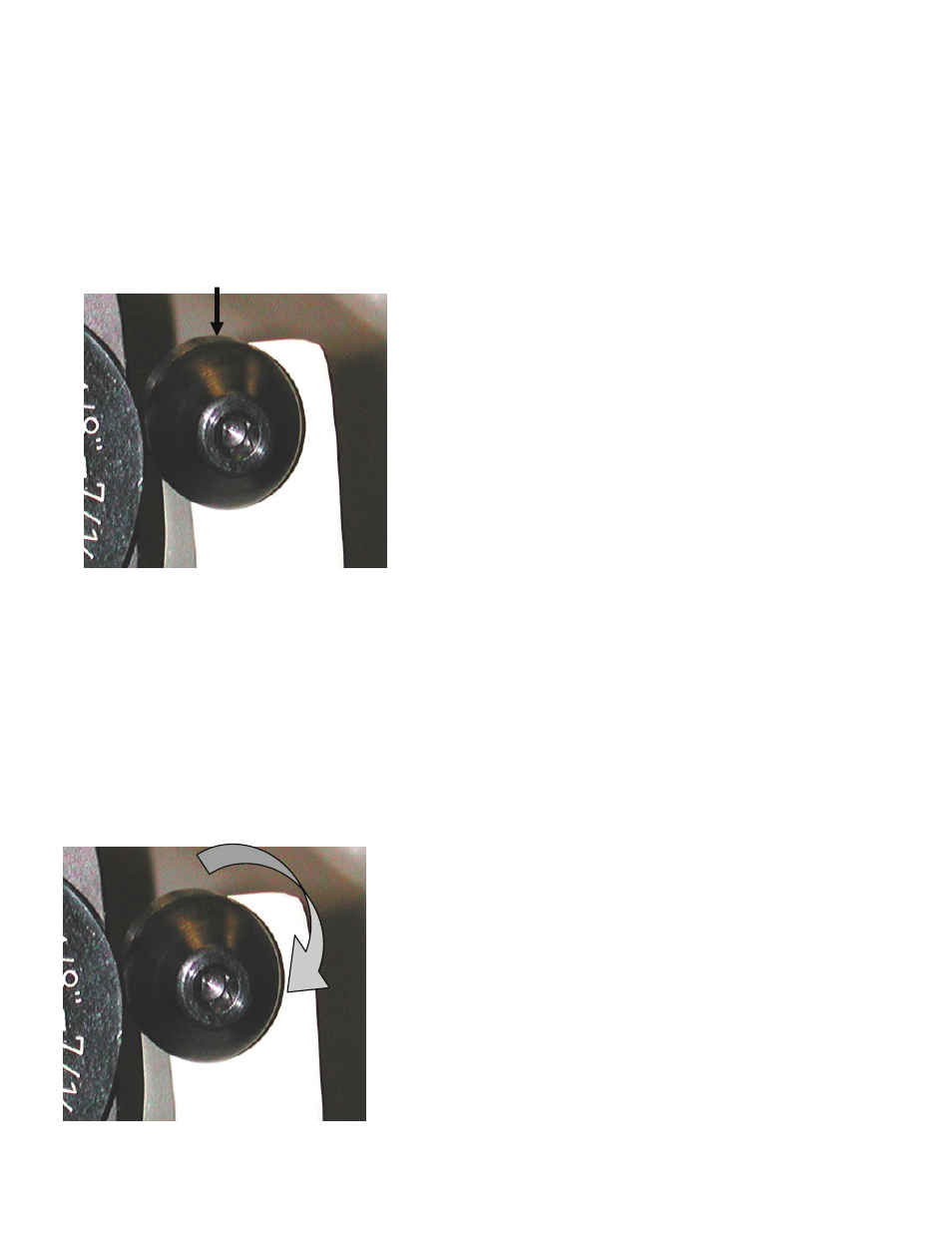

the wheel, an adjustment to the Swing Bearing

Assembly will need to be made. Loosen the

Swing Bearing Assembly located on the Pivot

Base Casting. Rotate the Swing Bearing Assem-

bly until the locating dot is positioned at 12o-

clock.

This bearing assembly is eccentric. The swing

cam on the chuck rests and rides on this bear-

ing. When rotated, the relationship between the

chuck cam and the bearing change the starting

and stopping point of the drill bit. Depending in

which direction you rotate the bearing you will

move tip of the drill either closer to, or further

from the angle of the grinding wheel. This will

change the amount of material removed from

the end of the drill. To increase the amount of

material removed, slightly rotate the bearing

clockwise.

90º - 120º Drill Attachment

LEX300

To decrease the material removed rotate the

bearing counterclockwise.

After adjusting, be sure to retighten, securing the

Swing Bearing Assembly. Re-sharpen the drill and

verify the corrected amount of material has been

removed. If incorrect, repeat procedure until the

desired amount has been removed. Approxi-

mately .010 should be the total amount of mate-

rial removed during sharpening.