Drill point splitting – Darex XT-3000A User Manual

Page 16

14

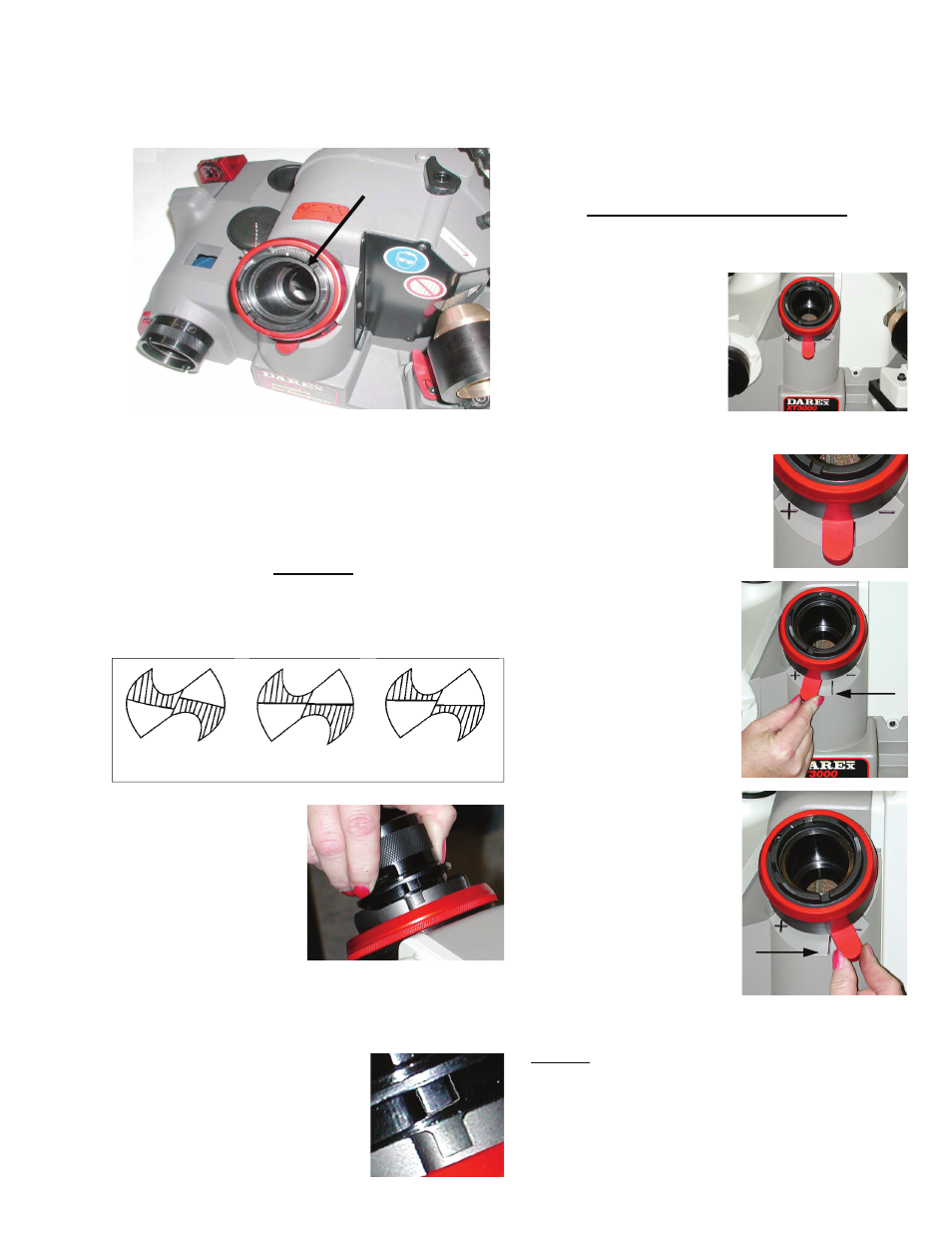

The Point Splitting Port is located in the center

of the machine.

Approximately 3-7° rake is created, producing a

drill with a self-centering point. Its advantages

are the ability to reduce thrust and eliminate

walking at the drill point. This is a distinct

advantage where drill bushings/fixtures are not

used.

Splitting

Upon completion of

the sharpening

procedure, Do Not

loosen the drill in the

chuck. Insert the

chuck into the point

splitting port. Align the

cam dogs with the

slots on the point split

tube. Let the weight of the chuck ease the drill

down and onto the grinding wheel. With slight

pressure, be sure the chuck stays seated in the

point splitter.

When the grinding noise is

reduced to near silence pull the

chuck out about 1/2 way and

rotate it 180 degrees to split

the opposite side of the drill

point.

NOTE: Do not force the chuck into the grinding

wheel or damage to the drill or wheel may

occur.

Adjusting the Depth of Split

The depth of split can vary from drill

manufacturer to drill manufacturer. The point

split depth adjustment

feature designed on the

XT-3000 makes it easy to

mimic multiple split

styles. The point split

depth adjustment lever is

attached to the point

split chuck tube. As you

move the lever, it backs the chuck tube away

from the wheel or moves it

closer into it.

1.

Located on the underside

of the point splitter is the

point split depth

adjustment lever.

2.

To increase the

depth of split, push

lever to the left

toward the + sign.

This will allow the

drill to travel deeper

into the wheel,

increasing the depth

of split.

3.

To decrease the

depth of split, push

the lever to the right

toward the – sign.

This will back the

drill away from the

wheel.

NOTE: To correct a drill that has been split

deeper than desired, you will have to regrind the

drill beyond the over split portion before splitting

again.

Drill Point Splitting

POINT SPLIT DIAGRAMS

DEPTH OF SPLIT DIAGRAM

Past Center

To Center

Below Center