Darex XT-3000A User Manual

Page 13

11

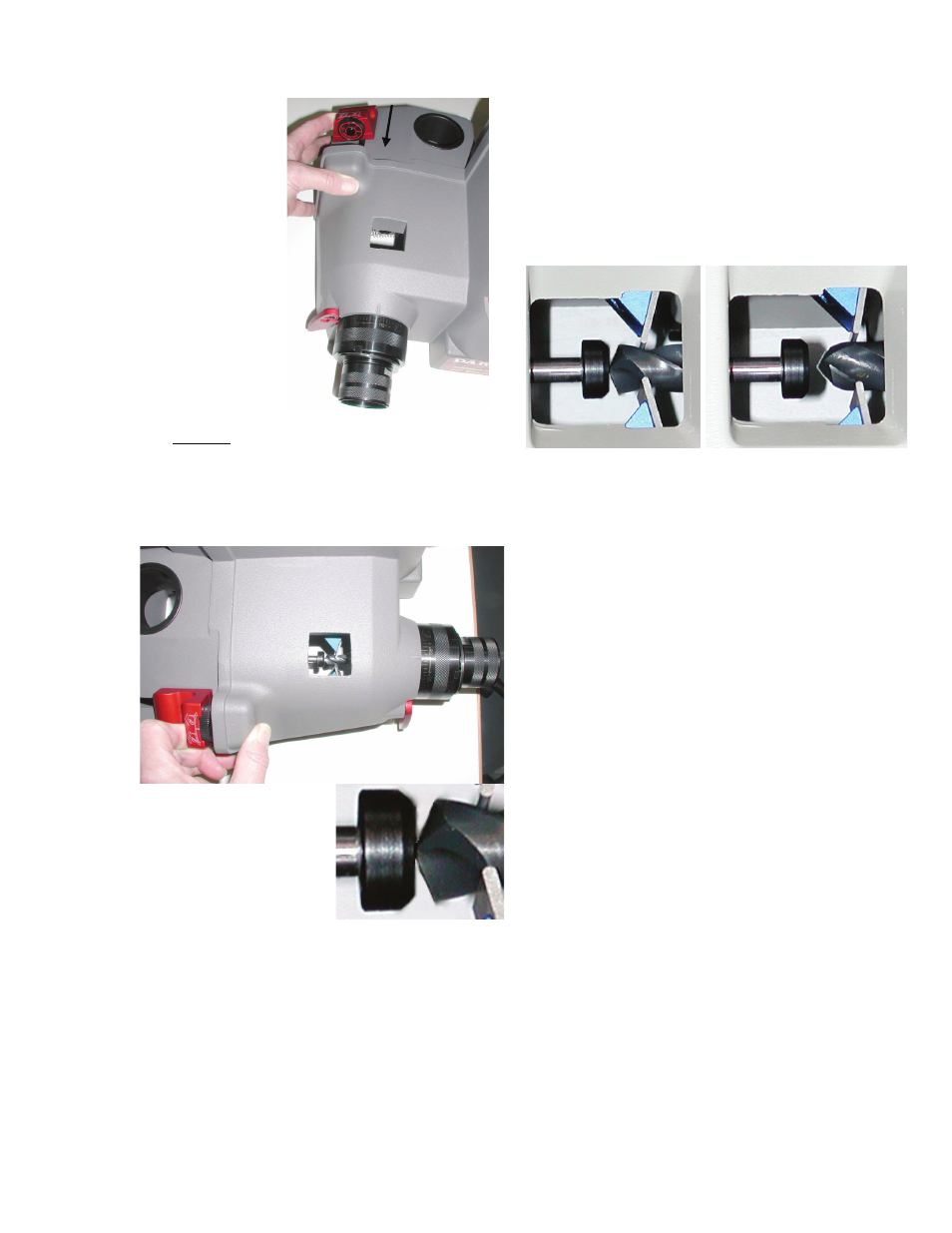

The pawls should be seated in the helix of

the drill. If incorrect, loosen chuck knob

and repeat step 4. The jaws are most likely

gripping the drill body too tightly and will

not allow the drill to rotate into position.

6.

Once the drill has been aligned correctly

and without releasing the slide handle,

tighten the chuck knob clockwise until the

chuck jaws grip the drill securely. Release

the slide handle and remove chuck from

alignment tube.

4.

S-L-O-W-L-Y

squeeze

together the

red slide

handle until it

touches

casting. We

emphasize

slowly,

because

squeezing the

handles too

quickly pushes

the drill too

deeply into

the chuck.

NOTE: If this happens, the drill will not

touch the wheel during the sharpening

process.

5. With the handles held together, look

through the viewing port and see if drill is

positioned correctly.

Drill point should be

touching the end of

the pusher shaft cap.

CORRECT

INCORRECT

Drill Alignment