Recalibrating material removal – Darex XT-3000A User Manual

Page 21

19

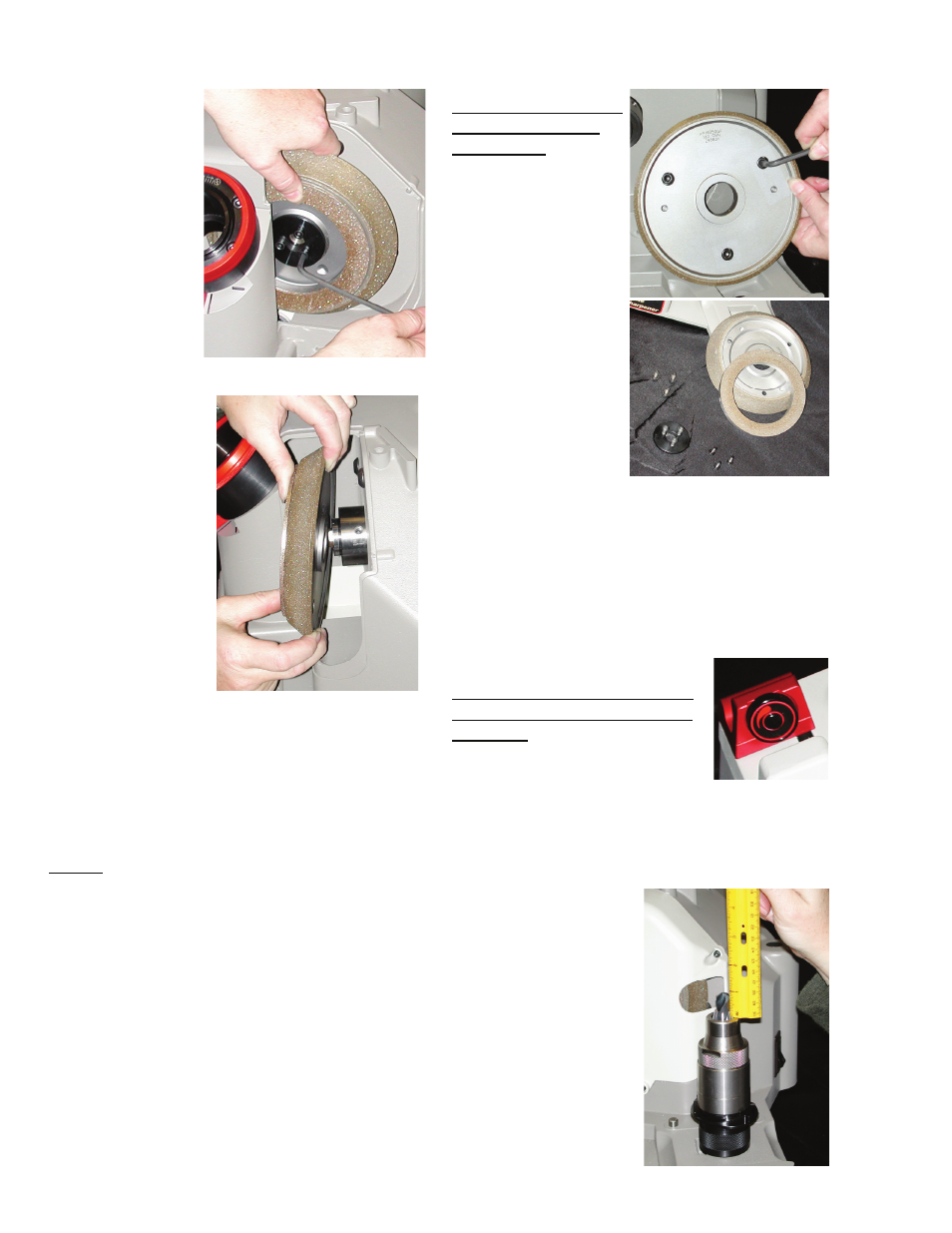

3.

Pull wheel

guard cover

away from

wheel.

4.

Using a 4 mm

hex key,

remove 3;

5mm socket

head cap

screws (PP16318FF) & split washer

(PP08650FF)

from grinding

wheel retainer.

5.

Remove the

wheel retainer.

6.

Pull wheel

toward you

then to the

right and out of

the machine

cavity.

7.

Clean the machine cavity as well as the

mounting hub and wheel before

reinstalling.

8.

Repeat steps in reverse to install new

wheel.

NOTE: Because the Darex grinding wheel

cannot be trued it is critical that the motor hub &

wheel register be cleaned. Once wheel has been

installed, rotate the wheel by hand to check that

the wheels run true. If not, loosen the screws ,

reposition the wheel and tighten the screws.

Separating grinding

wheel from point

split wheel

The grinding and point

split wheel are piggy

backed and bolted

together. To change

any one of the wheels

you must first

separate them. You

can access the bolts

from the back side of

the sharpening wheel.

1.

Using a 5mm

hex key, remove

the 3; 6mm

socket head cap

screws

(PP16348FF) & split washers.(PP07013FF)

2.

The two wheels can now be separated.

Recalibrating Material

Removal

After a wheel change, verify

and/or recalibrate material

removal.

Use a 3/8 HSS standard twist

drill, measure the length of drill

before sharpening.

1.

Rotate material removal knob to maximum

take off.

2.

Align drill as

though you intend

to sharpen it.

Follow Alignment

steps on page 9.

3.

Once drill is set to

length, aligned

and captured in

the chuck

securely, remove

from alignment

port.

Wheel Information