6 2 operational theory, 4 electronics and signal processing – Teledyne 3000TB-XL - Trace oxygen analyzer User Manual

Page 24

2-6

2 Operational Theory

Model 3000TB

XL

Teledyne Analytical Instruments

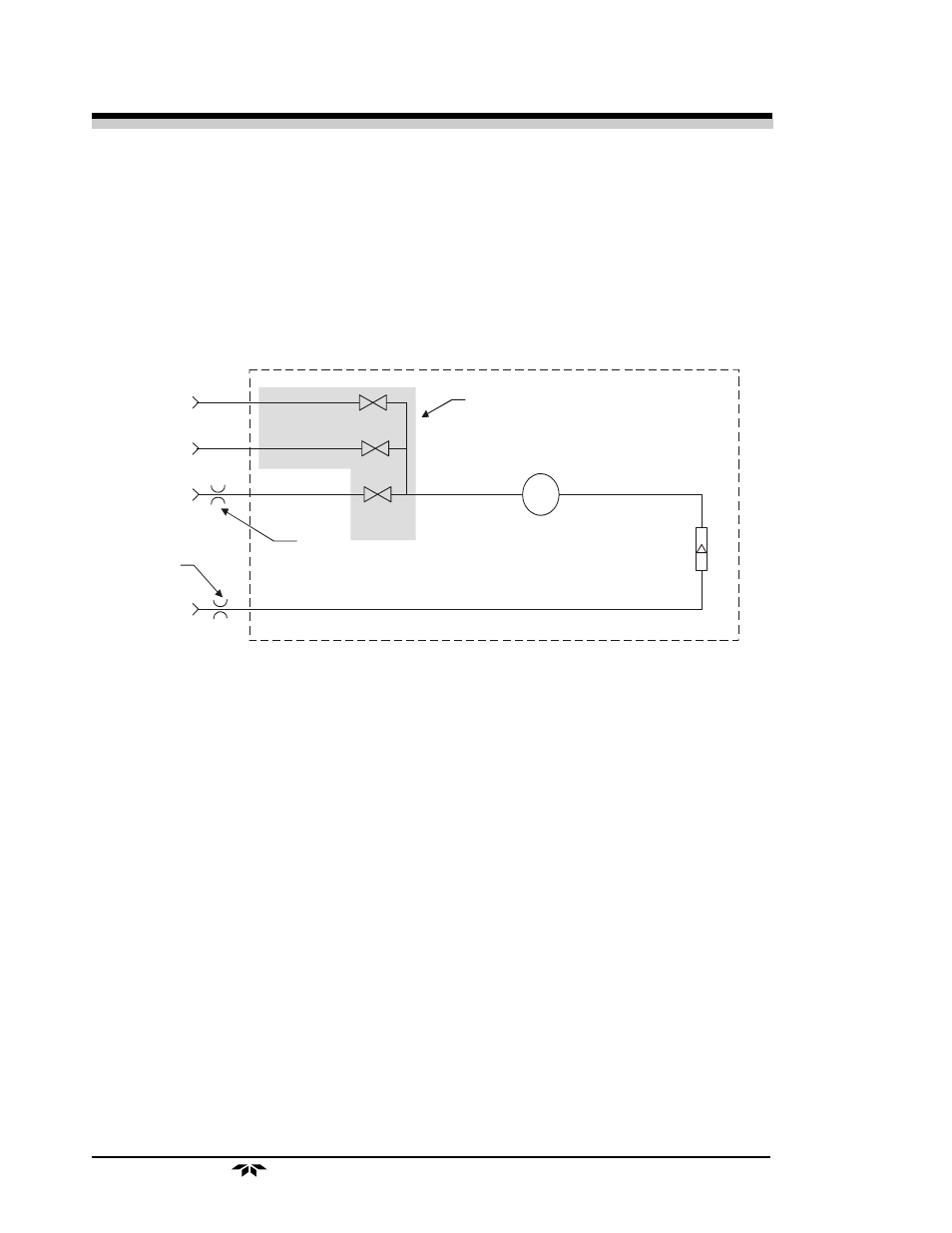

Figure 2-4 is the flow diagram for the sampling system. In the standard

instrument, calibration gases (zero and span) can be connected directly to the

Sample In port by teeing to the port with appropriate valves. The shaded

portion of the diagram shows the components added when the –C option is

ordered. The valves, when supplied, are installed inside the 3000TB

XL enclo-

sure and are regulated by the instruments internal electronics.

Figure 2-4: Flow Diagram

2.4

Electronics and Signal Processing

The signal processing and display electronics PCBs are mounted on the

back of the inner door. See Major Internal Components in chapter 5, for

illustration. The power supply module is mounted underneath the bottom end

of the Electrical Connector Panel.

The Model 3000TB

XL Trace Oxygen Analyzer uses an 8031 microcon-

troller with 32 kB of RAM and 128 kB of ROM to control all signal pro-

cessing, input/output, and display functions for the analyzer. System power

is supplied from a universal power supply module designed to be compatible

with most international power sources. CE approved units for the European

market also contain an EMI filter. Figure 2-5 is a simplified block diagram of

the Analyzer electronics.

In vacuum service the

restrictor should be

placed here.

Sample In

Span In

Zero In

Flowmeter

Exhaust Out

Solenoid

Valves

Restrictor

Cell

In normal service the

restrictor should be

placed here.

Components in the shaded area are in

the -C option (internal control valves)

only and are not shown in the piping

diagram above.