Installation, The fulton companies 2014, Figure 9 - wall penetration details – Fulton Endura (EDR) Condensing Hydronic Boiler User Manual

Page 28: Endura hydronic boiler

© The Fulton Companies 2014

INSTALLATION

EDR-IOM-2014-0318

SECTION 2

2-22

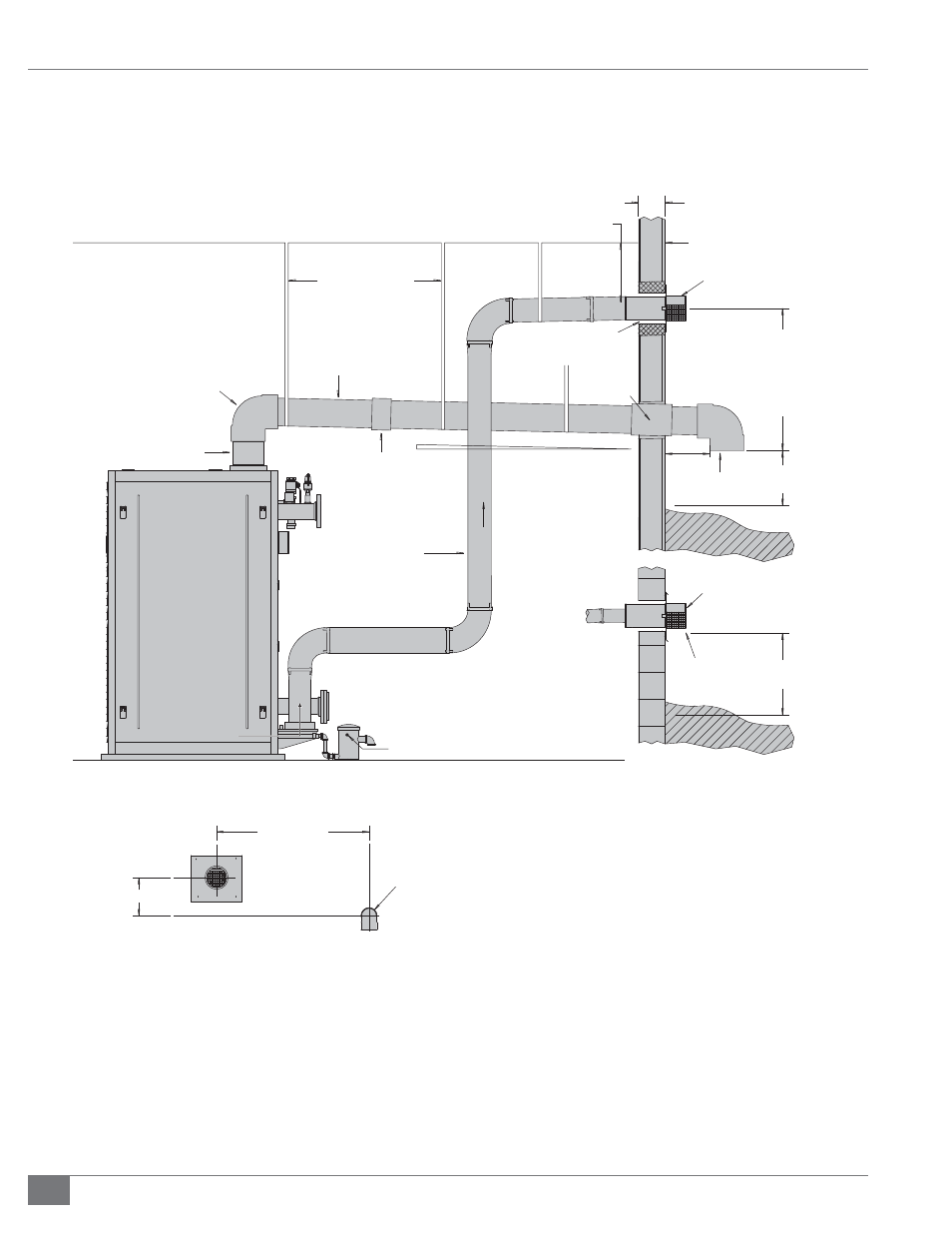

FIGURE 9 - WALL PENETRATION DETAILS

ENDURA

HYDRONIC

BOILER

COMBUSTIBLE WALL

PENETRATION DETAIL

NON-COMBUSTIBLE

WALL PENETRATION

PARTIAL DETAIL

AL29-4C or 316L STAINLESS STEEL

HIGH TEMPERATURE

EXHAUST PIPE & FITTINGS

INSTALL SUPPORT STRAP AT

5 FT / 150 CM HORIZONTAL

INTERVALS AND AT

INTERMEDIATE ELBOWS

(SPRING HANGERS ARE

RECOMMENDED)

10" PVC PIPE (U.S. ONLY)

COUPLING

REQUIRED AIR

SPACE CLEARANCE

COMBUSTIBLE WALL

WALL TERMINATION

( WITH SCREEN )

6 IN / 15 CM

MIN. / MAX. WALL THICKNESS

( 3 1/4 IN. - 20 IN. )

( 8.255 CM - 50.8 CM )

DO NOT PLACE INSULATION IN

REQUIRED AIR SPACE CLEARANCE

BAND SUPPORT

COLLAR

(TYP EACH SIDE)

SCREENED

TERMINATION

WALL TERMINATION

( WITH SCREEN )

1/4" TAPPING FOR WATER

100 PSI MAXIMUM (U.S. ONLY)

90° PVC ELBOW

SCREENED AIR INLET

EXHAUST PIPE

WALL PENETRATION

48 IN. / 122 CM.

48 IN. / 122 CM.

(MINIMUM)

AIR INTAKE

WALL PENETRATION

LOCATE INTAKE

UPWIND OF

EXHAUST PIPING

AIR INTAKE & EXHAUST PIPES WALL PENETRATION CLEARANCES

CAUTION:

AIR INTAKE AND EXHAUST TERMINATION SHOULD BE

SEPARATED AS FAR AS POSSIBLE TO PREVENT FLUE GAS

RECIRCULATION DURING DIFFERENT WIND CONDITIONS

NOTE:

MAINTAIN MINIMUM 9"/22.86 CM AIR SPACE

CLEARANCES TO COMBUSTABLES, WIRES AND INSULATION

AIR INLET

4 FT / 122 CM ( MINIMUM )

BETWEEN INLET & EXHAUST

OPENING ( SEE BELOW )

AIR INTAKE AND EXHAUST

TERMINATION SHOULD BE

SEPERATED AS FAR AS POSSIBLE

TO PREVENT FLUE GAS

RECIRCULATION DURING

DIFFERENT WIND CONDITIONS.

OPENING 1 FT / 30 CM ( MIN )

ABOVE NORMALLY EXPECTED

SNOW ACCUMULATION LEVEL

OPENING 1 FT / 30 CM ( MIN )

ABOVE NORMALLY EXPECTED

SNOW ACCUMULATION LEVEL

PVC

90° ELBOW

RISE TO RUN: 1/4" PER FOOT

EXHAUST