Installation, Prevent oxygen contamination – Fulton Endura (EDR) Condensing Hydronic Boiler User Manual

Page 14

© The Fulton Companies 2014

INSTALLATION

EDR-IOM-2014-0318

SECTION 2

2-8

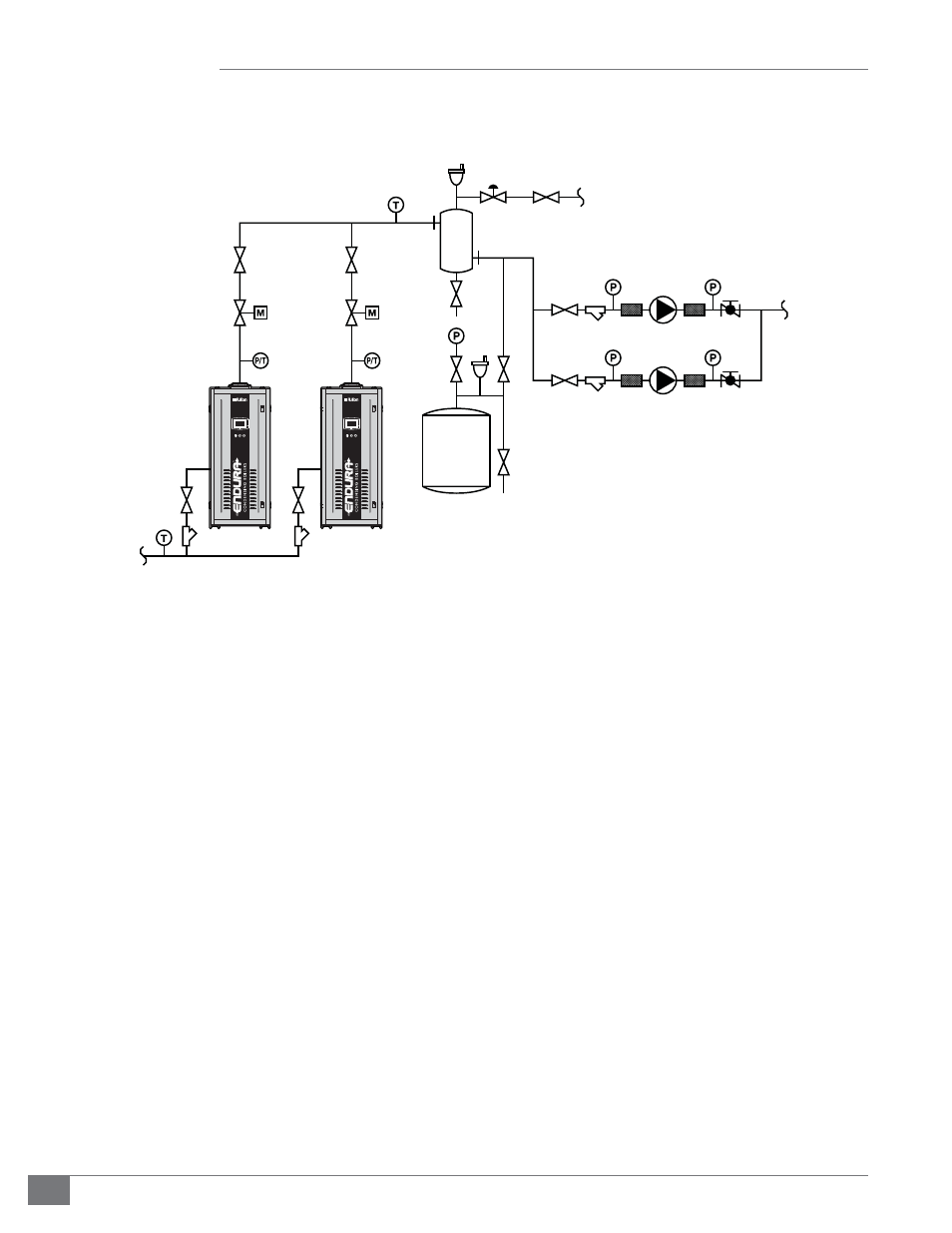

FIGURE 3 - SAMPLE PIPING LAYOUT

MOTORIZED

ISOLATION VALVE

(OPTIONAL)

SYSTEM

RETURN WATER

AIR

SEP

ARA

TOR

MAKE UP

WATER

AIR SEPARATOR AND EXPANSION

TANK AS DETERMINED

APPROPRIATE BY OTHERS

SYSTEM PUMPS AND VALVES

AS DETERMINED

APPROPRIATE BY OTHERS

EXPANSION

TANK

SYSTEM

SUPPLY

WATER

Makeup water pH range must be 7.5 - 8.8; the boiler

water must be maintained within pH range of 8.5 -

10.5.

4. Operate the boiler in a closed-loop system using water

or water/glycol (not requiring a make-up water supply).

A large amount of improperly treated make-up water

can cause premature failure of the heat exchanger

resulting from scale build up. Scale build up will reduce

the effi

ciency and useful life of the boiler and is not

covered under warranty.

5. For freeze protection an inhibited propylene glycol

is recommended. Only use mixtures formulated for

hydronic systems. Do not use automotive glycol.

6. At a minimum, the hydronic fl uid should be checked for

glycol concentration and pH once a year.

Note: Sample piping layout (P&ID) is a general representation of system installation. Good practice should be used in system design,

including but not limited to adequate pipe/valve sizing and natural fl ow path for system water.

Prevent Oxygen Contamination

There are several ways to prevent boiler water oxygen

contamination:

Minimize system leaks to minimize make up water

requirement

Do not use open tanks or fi ttings

Do not use oxygen permeable materials anywhere in

the water system

Repair leaks in the system quickly

Eliminate fi ttings wherever possible

Use air elimination devices in system piping