Installation, Combustion air supply from the boiler room, Air piped from outside boiler room – Fulton Endura (EDR) Condensing Hydronic Boiler User Manual

Page 22

© The Fulton Companies 2014

INSTALLATION

EDR-IOM-2014-0318

SECTION 2

2-16

13. In Canada, for recommended practice, refer to CSAB1.

Combustion Air Supply From the Boiler Room

Adhere to the following for installation:

1. Adequate combustion air and ventilation must be

supplied to the boiler room in accordance with local

codes and NFPA54/ANSI Z233.1, Section 5.3, Air for

combustion and ventilation. Ensure space and nearby

products are evaluated for the potential of combustion

air contaminants. See Table 6.

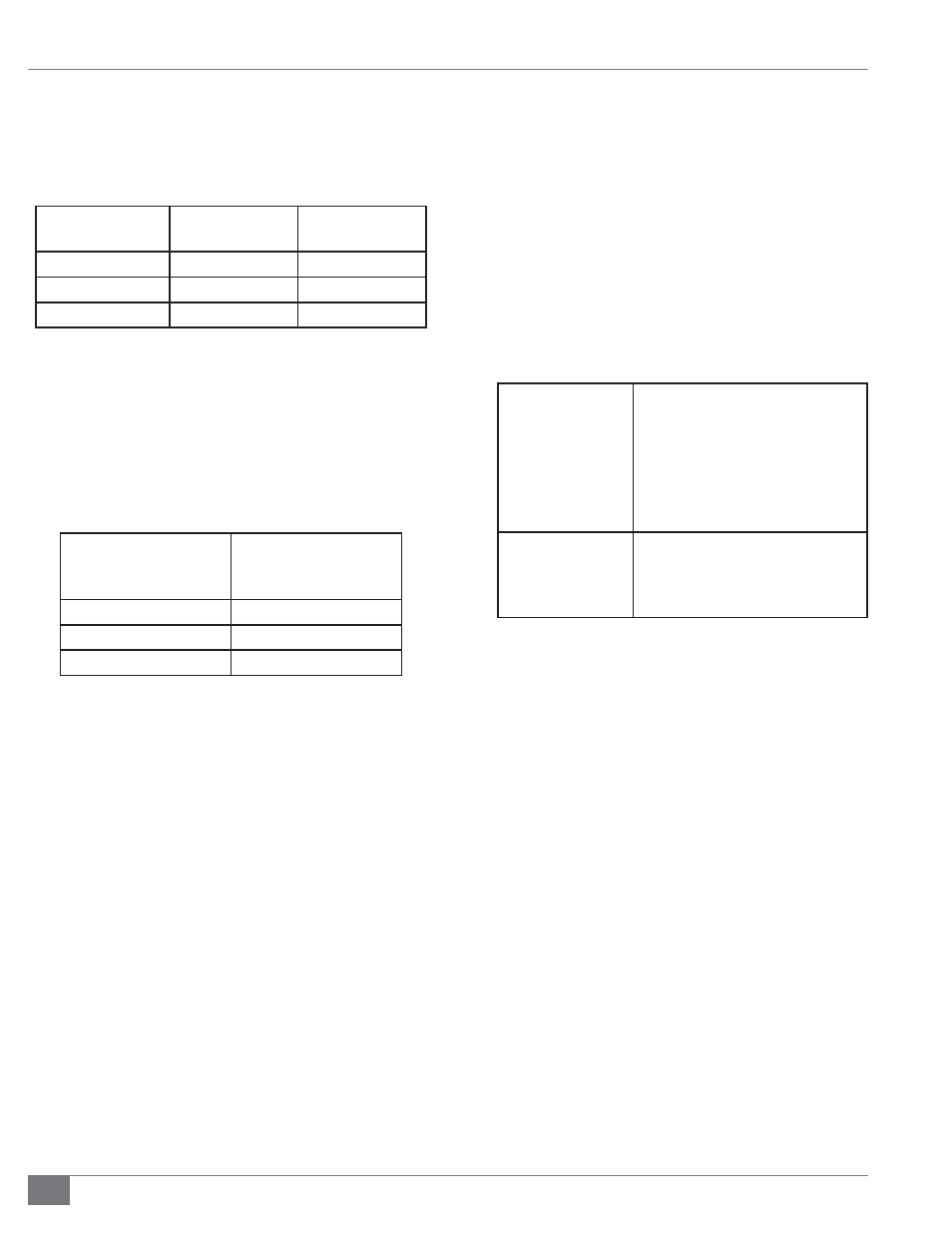

TABLE 6 - PRODUCTS/CONTAMINANTS TO AVOID

Products to avoid

Products containing chloro/fl ouro-

carbons; chlorine-based products;

calcium chlroide products, sodium

chloride products, paint and varnish

removers, hydrochloric acid, muri-

atic acid, cements, glues, antistatic

fabric softeners

Areas with the

potential to have

contaminants

Dry cleaning/laundry areas; swim-

ming pools; repair shops; process-

ing plants; manufacturing plants,

new construction

2. The boiler room must meet the NFPA criteria for a non-

confi ned space.

3. It is important to provide free access of air to the boiler.

Per ASME Section VI Para. 6.04 and NBIC, unobstructed

air ventilation openings (one near ceiling, one near

fl oor) should be sized on the basis of one square inch

free area per 2000 BTU/HR maximum fuel input of the

combined burners located in the boiler room. This is

subject to state and local regulations.

4. Consistent proper ventilation of the boiler room is

essential for good combustion. Install two fresh air

openings, one at a low level, 24” (610 mm).

5. Boiler room pressure must be neutral relative to the

outdoors.

6. Ensure there is not negative pressure in the boiler room.

If any negative pressure is present, sealed combustion

to the outdoors must be ensured.

Air Piped From Outside Boiler Room

Adhere to the following for installation:

1. The combustion air supply can be piped directly to the

to turn around)

Never direct fl ue stacks in a downward

direction.

TABLE 4 - GENERAL VENTING REQUIREMENTS

Endura Model

Number

Maximum

Negative Draft

Maximum

Positive Draft

EDR-1000

-0.04”W.C.

+1.50 “ W.C.

EDR-1500

-0.04 “ W.C.

+1.50 “ W.C.

EDR-2000

-0.04 “ W.C.

+1.50 “ W.C.

7. It is the responsibility of the designer and installer of

the venting system to guarantee the prevention of fl ue

gas recirculation (fl ue gases being drawn into a boiler’s

combustion air supply, or fl ue gases moving backward

through an idle boiler).

8. Make-up air ventilation openings are recommended for

each installation size in Table 5.

TABLE 5 - MAKE-UP AIR VENTILATION OPENINGS

Total Input of Boiler

1000 BTU/HR

(kW)

Free Area

square feet

(meters)

1000 (293)

3.5 (0.325)

1500 (439)

5.2 (0.48)

2000 (586)

6.9 (0.64)

9. For multiple boiler installations, multiply the number of

boilers by required free area per boiler.

10. The installation of exhaust fans in a boiler room is not

recommended.

11. An exhaust fan or similar equipment can create down

draft in the stack or restrict the burner’s air supply which

will result in poor combustion. It is essential that only

fresh air is allowed to enter the combustion air system.

Foreign substances, such as combustible volatiles in the

combustion system can create hazardous conditions.

If foreign substances can enter the air stream, the

boiler combustion air inlet must be piped to an outside

location.

12. Particulate matter or chemicals (example:

perchlorethylene, halogenated compounds) in the

combustion air supply to the boiler will cause damage

or failure to the burner. High-risk situations for

particulate matter to be in the air include construction

and maintenance activities. See Table 6.