PASCO OS-8535 LINEAR TRANSLATOR User Manual

Page 6

2

Basic Optics Linear Translator

012-06551A

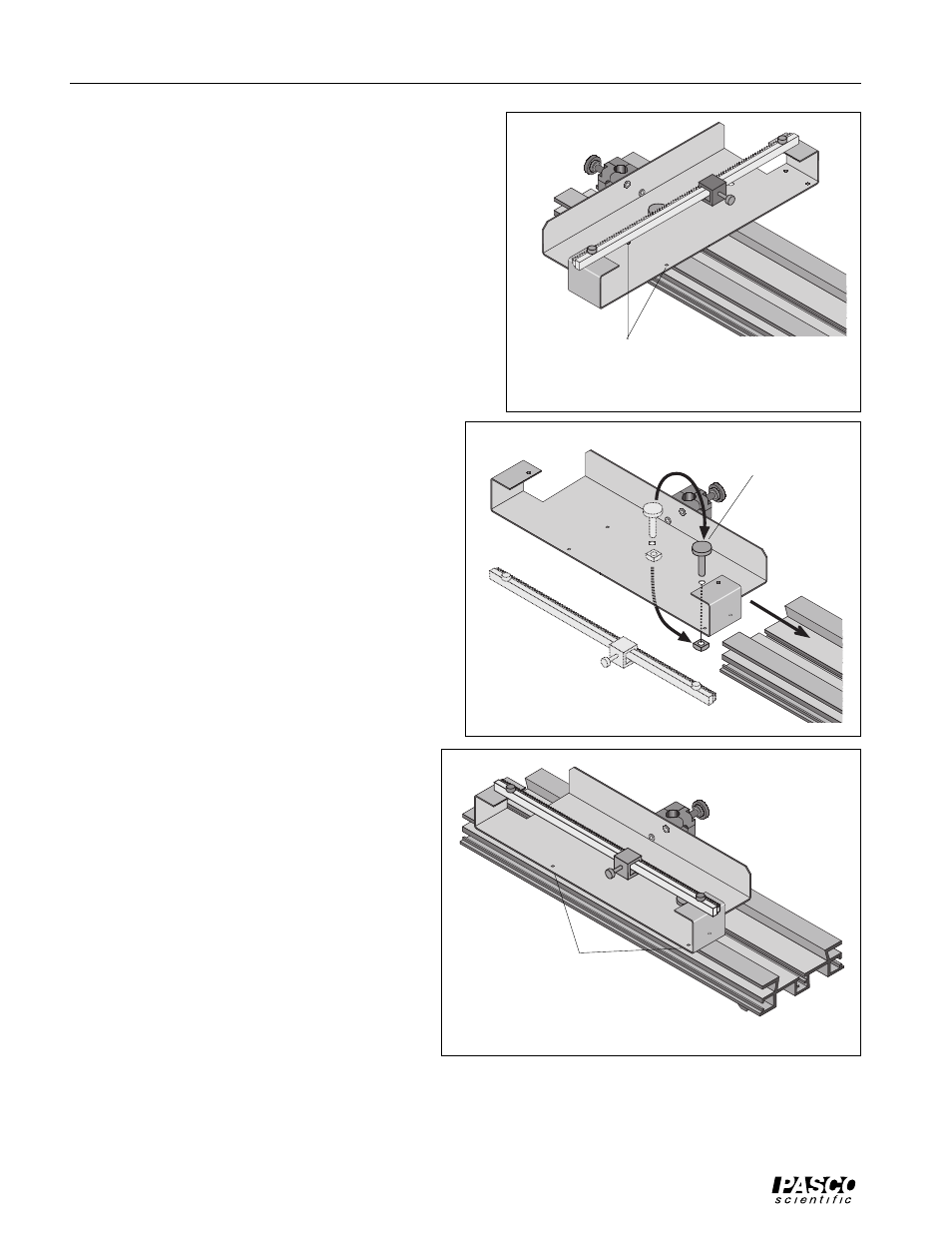

The alignment studs rest against the

edge of the Optics Bench

Figure 2: Linear Translator on Optics Bench

Pependicular Mount

To mount the Linear Translator so the Rack is perpendicular,

leave the mounting hardware (thumbscrew and square nut) in

the center hole. Loosen the thumbscrew by turning the thumb-

screw counter-clockwise while holding the square nut. Leave

the square nut on the end of the thumbscrew.

Attach the base to the Optics Bench by inserting the square nut

into the T-slot located along the center of the Optics Bench.

Use the two widely spaced alignment studs on the underside of

the base to align the Linear Translator with the edge of the Op-

tics Bench.

The Linear Translator can be moved to any position along the

Optics Bench while the thumbscrew is loose. Tighten the

thumbscrew to secure the Linear Translator in position.

Parallel Mount

To mount the Linear Translator so the Rack is parallel to

the Optics Bench, move the mounting hardware from the

center hole to the off-center hole (see Figure 3.1).

Turn the Linear Translator so the Rack is parallel to the

Optics Bench. Insert the square nut into the T-slot lo-

cated along the center of the Optics Bench.

Move the mounting hardware to

the off-center hole.

Slide the square nut

into the T-slot.

Figure 3.1

Figure 3.2: Linear Translator Parallel to Optics Bench

The alignment studs rest against

the edge of the Optics Bench.

Using a Rotary Motion Sensor

You can mount a PASCO Model CI-6538 Rotary Mo-

tion Sensor or the Model CI-6625 Rotary Motion Sensor

for ULI on the rack of the Linear Translator.

The Rotary Motion Sensor has a T-slot into which

you can slide the Rack of the Linear Translator. The

first step is to remove the rack thumbscrews from the

ends of the Rack. Turn the thumbscrews counter-

clockwise to remove them.

You may also want to remove the Rack Clamp from

the Rack. Turn the rack thumbscrew counter-clock-

wise until you can slide the Rack Clamp off the end

of the Rack.

If you are using the three-step pulley on the Rotary

Motion Sensor, hold the Rotary Motion Sensor so the

three-step pulley is on top. Line up the Rack with the

T-slot on the side of the Rotary Motion Sensor. The

teeth on the Rack go through the narrow side of the

T-slot and then engage a gear that is on the shaft of

the Rotary Motion Sensor. Gently push the Rack

through the T-Slot and into the sensor.