Assembly – PASCO SE-8657 MOTOR ACCESSORY User Manual

Page 8

4

Motor Accessory

012-06247A

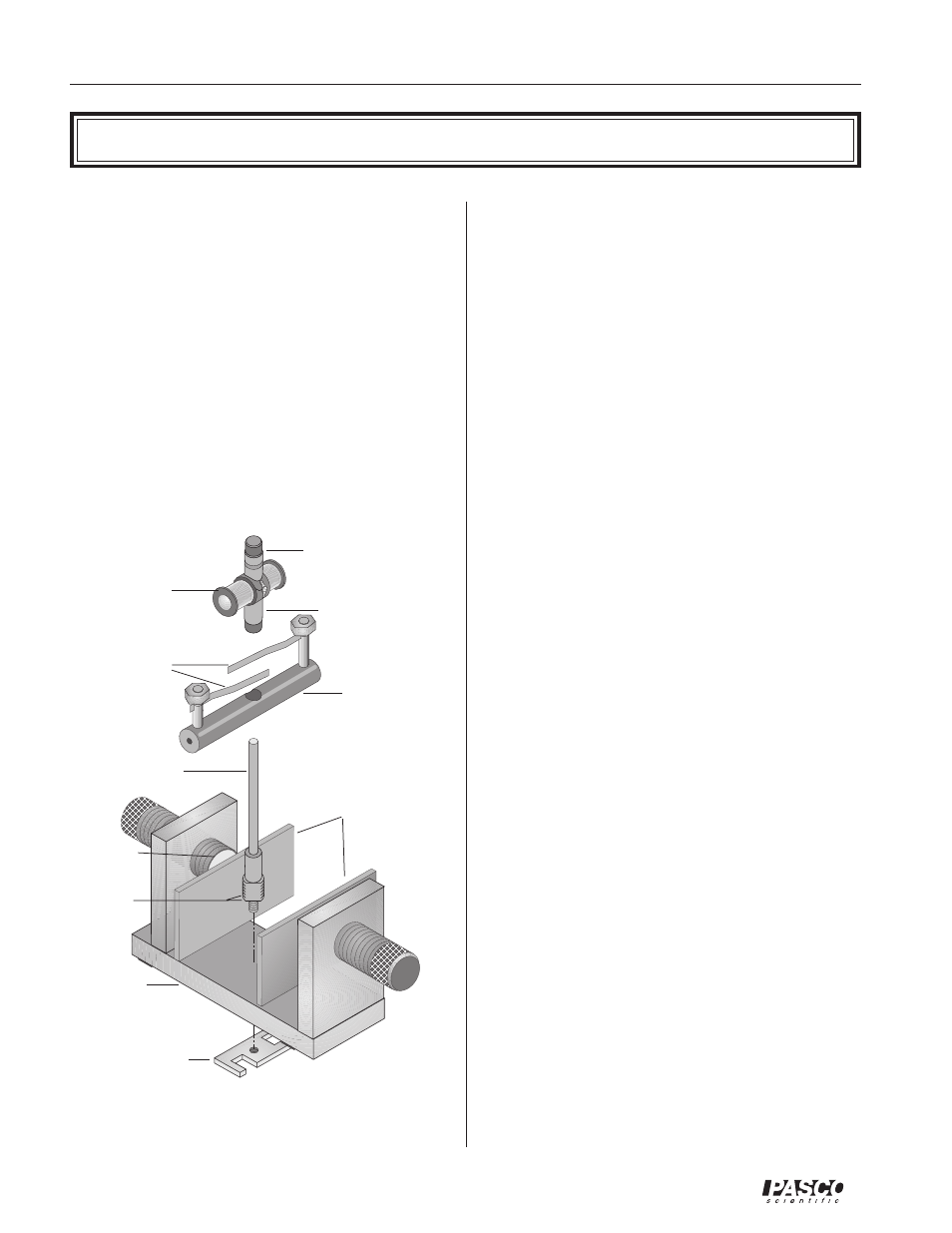

¨

Motor Accessory onto the Variable Gap

Magnet

➀

Be sure you have the flat iron pole pieces placed on

the two neodymium magnets of the Variable Gap

Magnet. The larger threaded portion of the shaft

screws easily, without tools, into the threaded hole

in the magnet base. Insert the threaded end of the

shaft from above, screwing it in until 1 mm, or

slightly less, of the threaded portion remains above

the upper surface of the base.

➁

Turn the magnet over and screw the retaining nut

onto the smaller diameter threaded portion of the

Assembly

shaft that protrudes through the bottom of the mag-

net base. (Note that the retaining nut has a metric

thread, size M6-1.0.) Use firm finger pressure. If

this should prove inadequate, tighten the nut some-

what more with a wrench. If an appropriate wrench

is not at hand, use a heavy metal object to tighten

the nut by tapping the edge of the nut. Do not use

a pole piece of the magnet to tighten the nut be-

cause that might mar the finish of the pole piece.

Do not over tighten.

➂

Working from above, press the brush holder onto

the smooth, enlarged portion of the shaft. Apply

increasingly firm pressure equally to each side of

the brush holder while rotating the brush holder

back and forth. If this action loosens the retaining

nut, tighten it more tightly, as described in step 2.

Check to be sure the brush assembly is seated as far

down on the shaft as it will go.

➃

Gently lower the armature onto the shaft. To make

a DC motor, the split ring commutator should be

down; for an AC motor, the dual slip-ring commu-

tator should be down. Carefully rotate the arma-

ture back and forth to separate the brushes and al-

low the commutator to slip down between them. If

necessary, insert a pencil or similar object down

between the brushes. Use only the most delicate

force to avoid bending the brushes and necessitat-

ing adjustments or repairs.

➄

Adjust the gap of the Variable Gap Magnet so there

is approximately 1 mm of clearance between the

pole pieces and the armature when it is rotated by

hand.

➅

Refer to the instructions included in experiments 1-

4 for details of the electrical connections.

Motor AccessoryVariable Gap Magnet Assembly

armature

wrench/retaining

nut

brushes

brush holder

dual slip-ring commu-

tator

split ring

commutator

(this end down for

AC motor)

(this end down for

DC motor)

leave 1mm

exposed at

installation

shaft

magnet base

flat pole pieces

neody-

mium

magnet