PASCO SE-8657 MOTOR ACCESSORY User Manual

Page 24

20

Motor Accessory

012-06247A

¨

➂

Working from above, press the brush holder onto the smooth, enlarged portion of the

shaft. Apply increasingly firm pressure equally to each side of the brush holder while

rotating the brush holder back and forth. If this action loosens the retaining nut, tighten

it more tightly, as described in step 2.

Check to be sure the brush assembly is seated as far down on the shaft as it will

go.

➃

Gently lower the armature onto the shaft with the dual slip- ring commutator down.

Carefully rotate the armature back and forth to separate the brushes and allow the

commutator to slip down between them. If necessary, insert a pencil or similar object

down between the brushes. Use only the most delicate force to avoid bending the

brushes and necessitating adjustments or repairs.

➄

Adjust the gap of the Variable Gap Magnet so there is approximately 1 mm of clearance

between the flat pole pieces and the armature when it is rotated by hand.

Procedure—Part A

➀

Remove the armature from the shaft by grasping it between your thumb and forefinger

and rotating it back and forth while lifting gently. If necessary, insert a pencil between

the brushes to gently separate them so they don’t prevent removal of the armature.

➁

Examine the armature closely and imagine current entering one of the two slip rings

from a brush. Trace the path of the current through the wire to the coil, through the coil,

through the wire to the coil on the opposite side of the armature, through that coil, and

through the wire to the other slip ring and into the second brush. By carefully examin-

ing the part of the coils where the leads emerge from the coil, you should be able to

determine the direction in which the wire is wound on the coil.

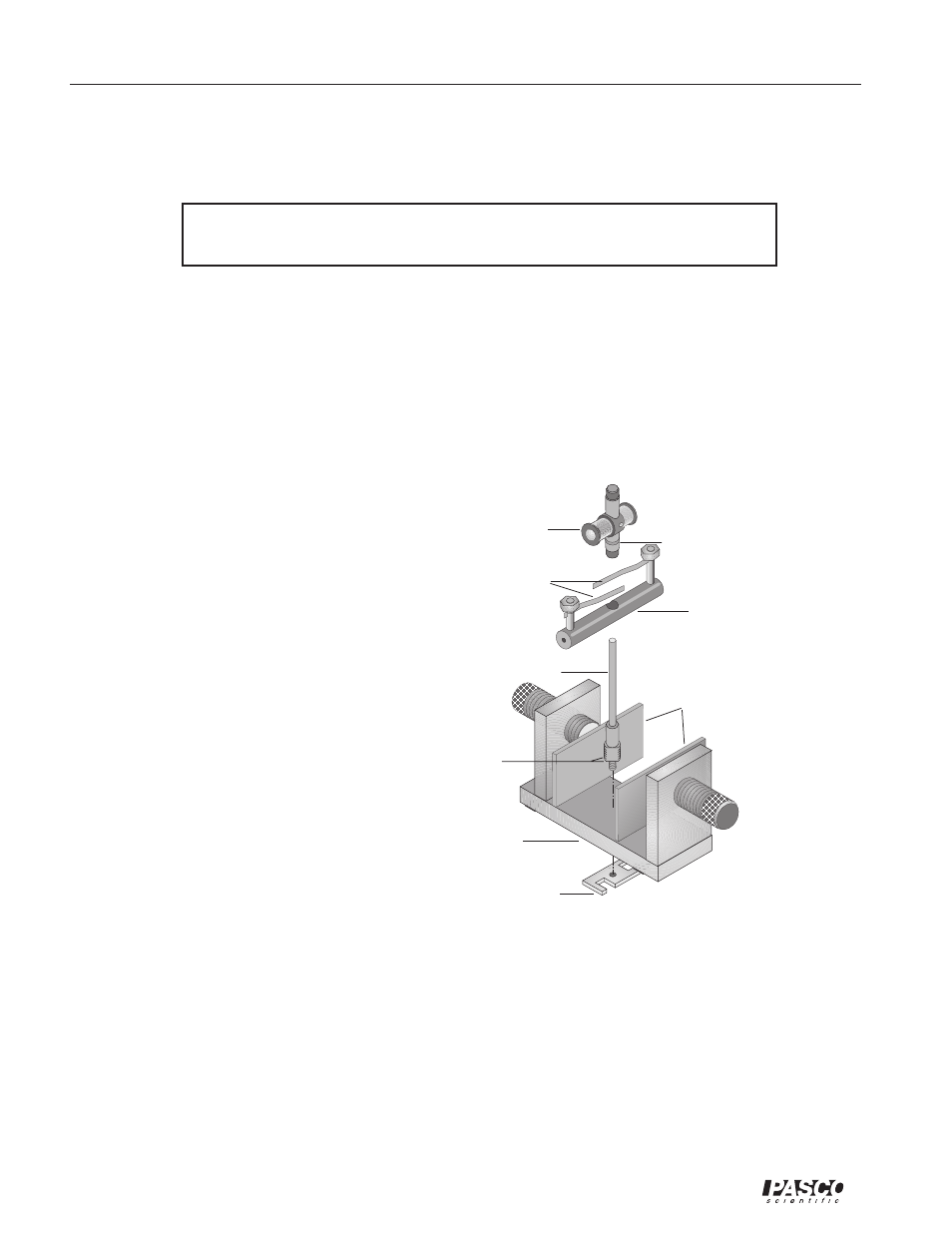

Figure 1. Installation of the Motor

Accessory onto the Variable Gap

Magnet

armature

wrench/

retaining nut

brushes

brush holder

dual slip-ring

commutator

leave 1mm

exposed at

installation

shaft

magnet

base

flat pole pieces