Experiment 4: operation of the universal motor – PASCO SE-8657 MOTOR ACCESSORY User Manual

Page 29

25

012-06247A

Motor Accessory

¨

Experiment 4: Operation of the Universal Motor

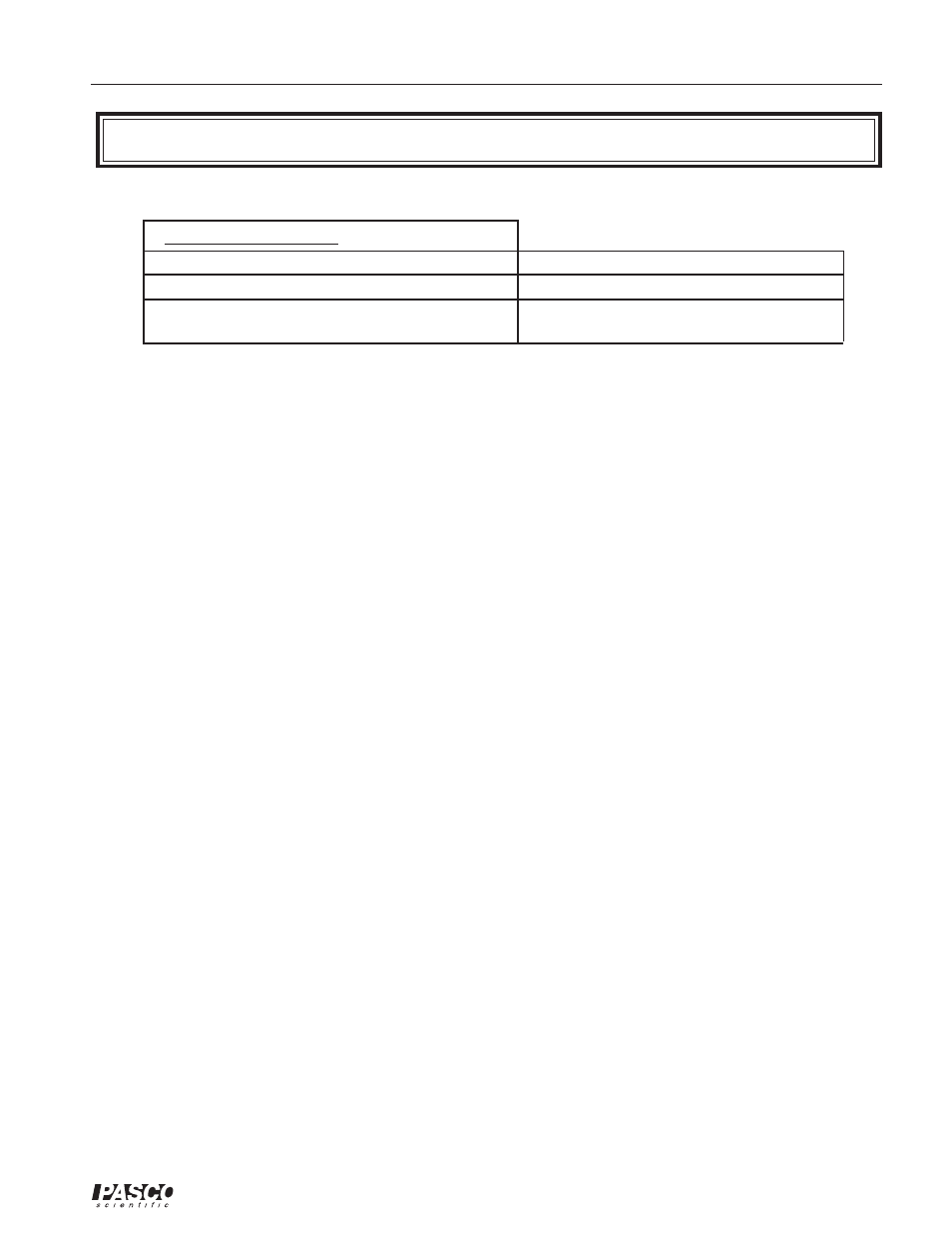

Equipment needed:

•

Motor Accessory

•

multimeter

•

Coils and Cores Set

•

patch cords

•

power source that will deliver both DC and

AC current at 1.0 A

Purpose

The purpose of this experiment is to demonstrate the operation of the universal motor in

terms of basic concepts of electromagnetism.

Theory

When current passes through the coils mounted on the U-shaped core of the Coils and

Cores apparatus, the core may be thought of as an electromagnet possessing north and

south poles that interact with the north and south poles of the armature (another electro-

magnet). Like poles repel, while unlike poles attract. The armature rotates until its north

pole is as close as possible to the south pole of the permanent magnet (and also as far as

possible from the north pole) At that moment, the action of the split ring commutator

reverses the direction of current in the armature, which reverses the poles of the armature,

promoting another half-turn.

When the coils on the U-shaped core are in series with the coils of the armature, the

configuration is called a “universal motor.” The term comes from the fact that it will

operate on either DC or AC current. With alternating current, the changes in direction of

the current cause reversals in both the poles of the U-shaped core and the armature, so

attraction or repulsion between poles is the same as with direct current. In terms of the

magnetic fields, with direct current, the magnetic field of the armature reverses every half

turn and the magnetic field of the coils does not. With alternating current, the opposite

happens. Either way, the armature keeps turning.

Setup

➀

Begin with the U-shaped core, with the coils and any other parts removed. The smaller

threaded portion of the shaft screws easily into the threaded hole in the core so the shaft is

between the poles of the core. Use the wrench provided to tighten the shaft by gripping

the flats on the larger threaded portion. The small wrench limits the torque that can be

applied. If an ordinary wrench is used, be careful not to over tighten. Do not discard the

small wrench; it is essential as a retaining nut when the Motor Accessory is used with the

Variable Gap Magnet.

➁

Working from above, press the brush holder onto the smooth, enlarged portion of the

shaft. Apply increasingly firm pressure equally to each side of the brush holder while

rotating the brush holder back and forth. If this action loosens the shaft, tighten it as

described in step 1.