Figure 2. experimental setup, Flat pole pieces – PASCO SE-8657 MOTOR ACCESSORY User Manual

Page 12

8

Motor Accessory

012-06247A

¨

➂

Working from above, press the brush

holder onto the smooth, enlarged portion

of the shaft. Apply increasingly firm

pressure equally to each side of the brush

holder while rotating the brush holder

back and forth. If this action loosens the

retaining nut, tighten it more tightly, as

described in step 2.

Check to be sure the brush assembly

is seated as far down on the shaft as it

will go.

➃

Gently lower the armature onto the shaft

with the split ring commutator down.

Carefully rotate the armature back and

forth to separate the brushes and allow

the commutator to slip down between

them. If necessary, insert a pencil or

similar object down between the brushes.

Use only the most delicate force to avoid

bending the brushes and necessitating

adjustments or repairs.

➄

Adjust the gap of the Variable Gap

Magnet so there is approximately 1 mm

of clearance between the flat pole pieces

and the armature when it is rotated by

hand.

➅

Connect the positive terminal of the DC

power supply to one end of the brush

holder with a red patch cord by plugging

the banana terminals into each.

➆

Connect the negative terminal of the DC

power supply to the other end of the

brush holder with a black patch cord.

Do not turn the power on.

Figure 1. Installation of the Motor Accessory

onto the Variable Gap Magnet

armature

wrench/retaining

nut

brushes

brush holder

dual slip-ring commu-

tator

split ring

commutator

leave 1mm

exposed at

installation

shaft

magnet

base

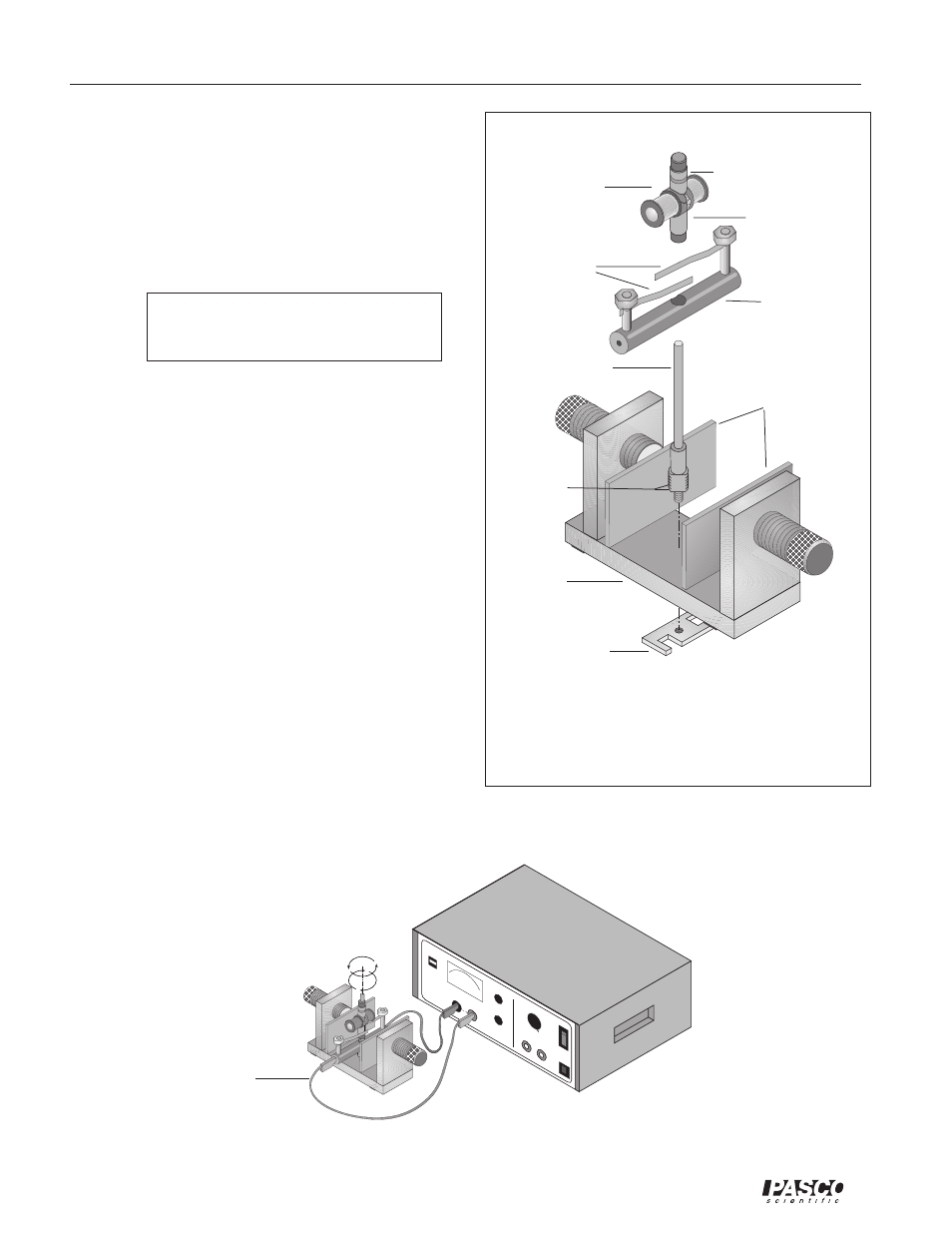

Figure 2. Experimental Setup

flat pole pieces

6 AMP

MAX

RESET

ON

OFF

PASCO

scientific

METER

PUSH FOR

CURRENT

DC CURENT

ADJUST

DC VOL

TAGE

ADJUST

2

4

6

8

12

14

16

18

20

22

24

10

AC VOL

TAGE

ADJUST

2 - 24 VOL

TS

AC OUTPUT

0 - 24 VOL

TS DC OUTPUT

8 AMP

MAX

MODEL

SF-9584 LOW VOL

TAGE

AC/DC POWER SUPPL

Y

wire connected to

the + terminal of the

power supply