PASCO TD-8579A COMPUTER-BASED THERMAL EXPANSION APPARATUS User Manual

Page 8

012-07599C

Computer-based Thermal Expansion Apparatus

5

®

Introduction

Most materials expand when heated through a temperature range that does not pro-

duce a change in phase. The added heat increases the average amplitude of vibration

of the atoms in the material, which increases the average separation between the

atoms.

Suppose an object of length L undergoes a temperature change of magnitude

∆

T. If

∆

T is reasonably small, the change in length,

∆

L, is generally proportional to L and

∆

T. Stated mathematically:

∆

L =

α

L

∆

T;

where

α

is called the coefficient of linear expansion for the material.

Materials that are not isotropic, such as an asymmetric crystal for example,

α

can have

a different value depending on the axis along which the expansion is measured. The

coefficient (

α)

can also vary somewhat with temperature. Therefore, the degree of

expansion depends not only on the magnitude of the temperature change, but also on

the absolute temperature.

In this experiment, you will measure

α

for copper, aluminum, and brass. These

metals are isotropic, so it is necessary to measure

α

along only one dimension. Also,

within the limits of this experiment,

α

does not vary with temperature.

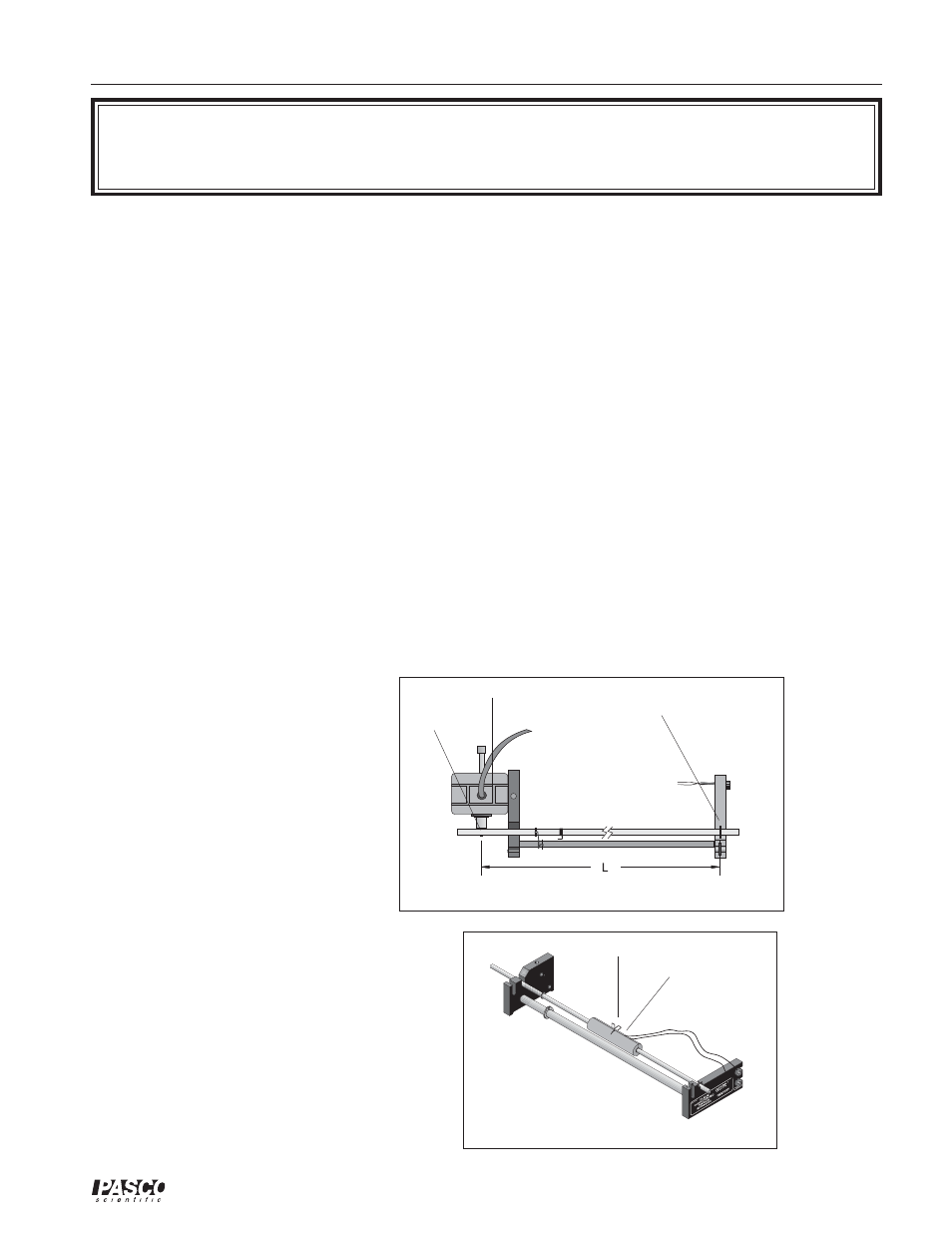

Figure 1: Measuring Tube Length

Experiment: Measuring the Coefficient of Linear

Expansion for Copper, Brass, and Aluminum

L = length

rotary

pin

1. With a measuring tape or

metric ruler, measure L, the

length of the aluminum rod,

at room temperature. Mea-

sure from the center of the

stainless steel ring (in the

groove of the small end

block), to the center of the

rotary pin at the other end

(see Figure 1). Record your

results in Table 1 in the Data

and Calculations section.

2. Insulate the rod and thermistor with

a slitted, tubular foam wrap. Slide

the foam wrap from underneath the

rod until the foam covers the

circumference of the rod. The

spring clamp should jut out from the

top of the foam slit (See Figure 2).

Figure 2: Insulating the rod

foam

spring clamp

retaining pin

rotary motion sensor

Procedure