Data analysis, Sample data – PASCO AP-8214A Stress_Strain Apparatus User Manual

Page 9

®

M o d e l N o . A P - 8 2 1 4 A

0 1 2 - 1 3 2 8 2 A

D a t a A n a l y s i s

9

•

Turn the crank clockwise. Starting just before the lever arm comes into contact

with the Force sensor, turn the crank very slowly.*

•

When you have finished collecting data, click Stop. (If you reach the maximum

force, DataStudio will stop automatically.) If the coupon breaks, it should break in

the middle. If the coupon breaks near the end, it was probably twisted slightly

when you mounted it, resulting in a point of higher stress where it broke.

4.

Rename the data run to identify the coupon. Use the same method you used to rename the calibration

data.

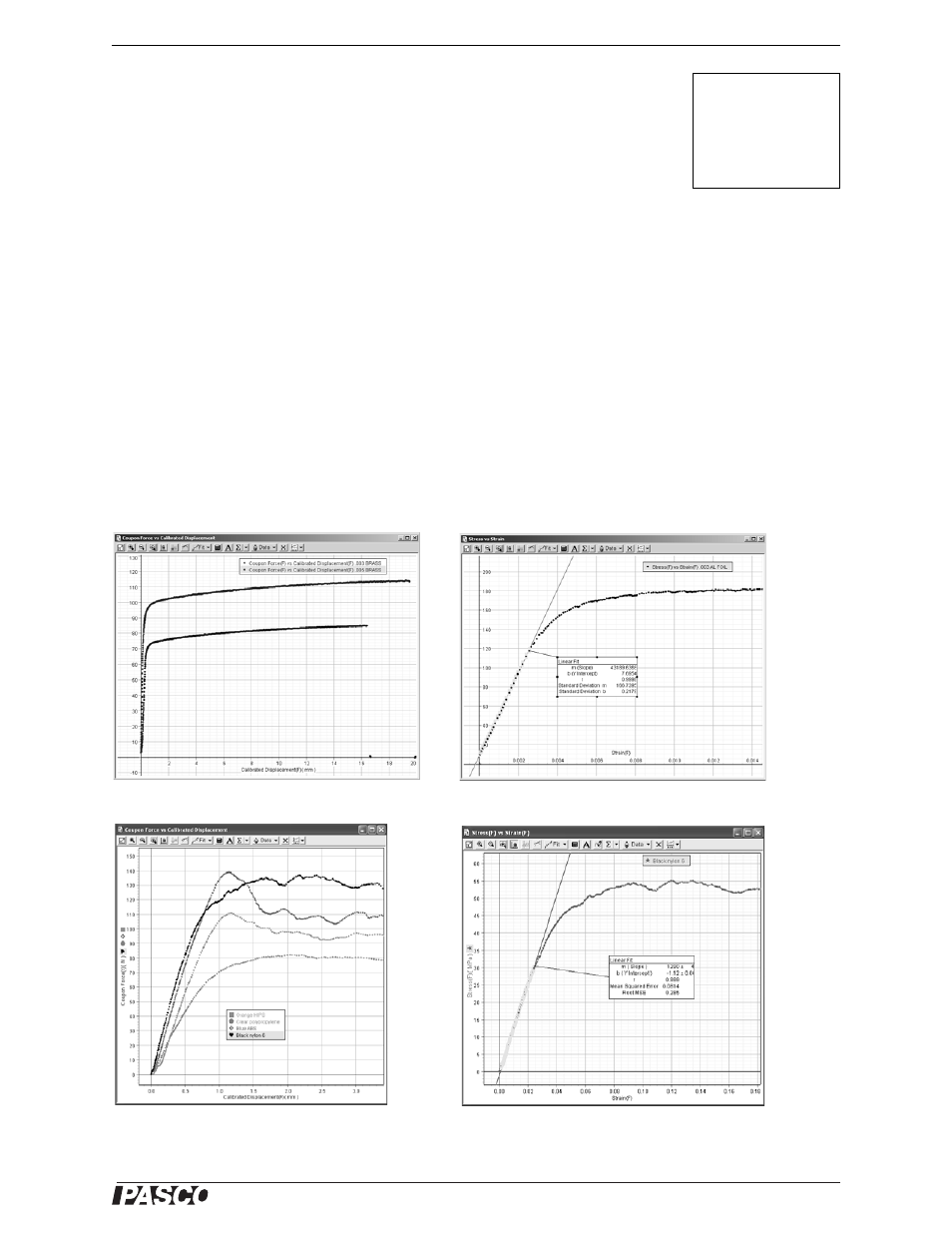

Data Analysis

On the Stress versus Strain graph, you can identify features such as the elastic region, the plastic region, the yield

point, and the break point.

To calculate Young's modulus, drag the mouse to select a data region covering the linear, lower left-hand part of the

graph. (You may find that the very first part of the plot is not linear. This nonlinearity is likely due to the straightening

of bends and twists in the coupon as force is first applied. Do not include this region in your selection.) Click the Fit

button to apply a linear curve fit to the selected data. The slope of the line is Young's modulus in units of MPa (or

MN/m

2

or N/mm

2

).

Sample Data

* When you observe on

the Stress versus Strain

plot that the material has

been stretched beyond

the elastic region, you

can begin to turn the

crank faster.

Sample 1: Force vs. displacement - brass 0.003 and

brass 0.005

Sample 2: Stress vs. strain - aluminum 0.003

Units of slope are MPa

Sample 3: Force vs. displacement -

plastic coupons

Sample 4: Stress vs. strain - black nylon 6

Units of slope are MPa