Test coupon specifications, Theory – PASCO AP-8214A Stress_Strain Apparatus User Manual

Page 3

®

M o d e l N o . A P - 8 2 1 4 A

0 1 2 - 1 3 2 8 2 A

I n tr o d u c t i o n

3

Test Coupon Specifications

The data below are intended as a general guide only and do not necessarily represent results that may be obtained.

The units for tensile strength and modulus of elasticity are megapascals (MPa or 10

6

N/m

2

) and pounds per square

inch (psi).

AP-8222 Plastic Test Coupons

AP-8223 Metal Test Coupons

Theory

.

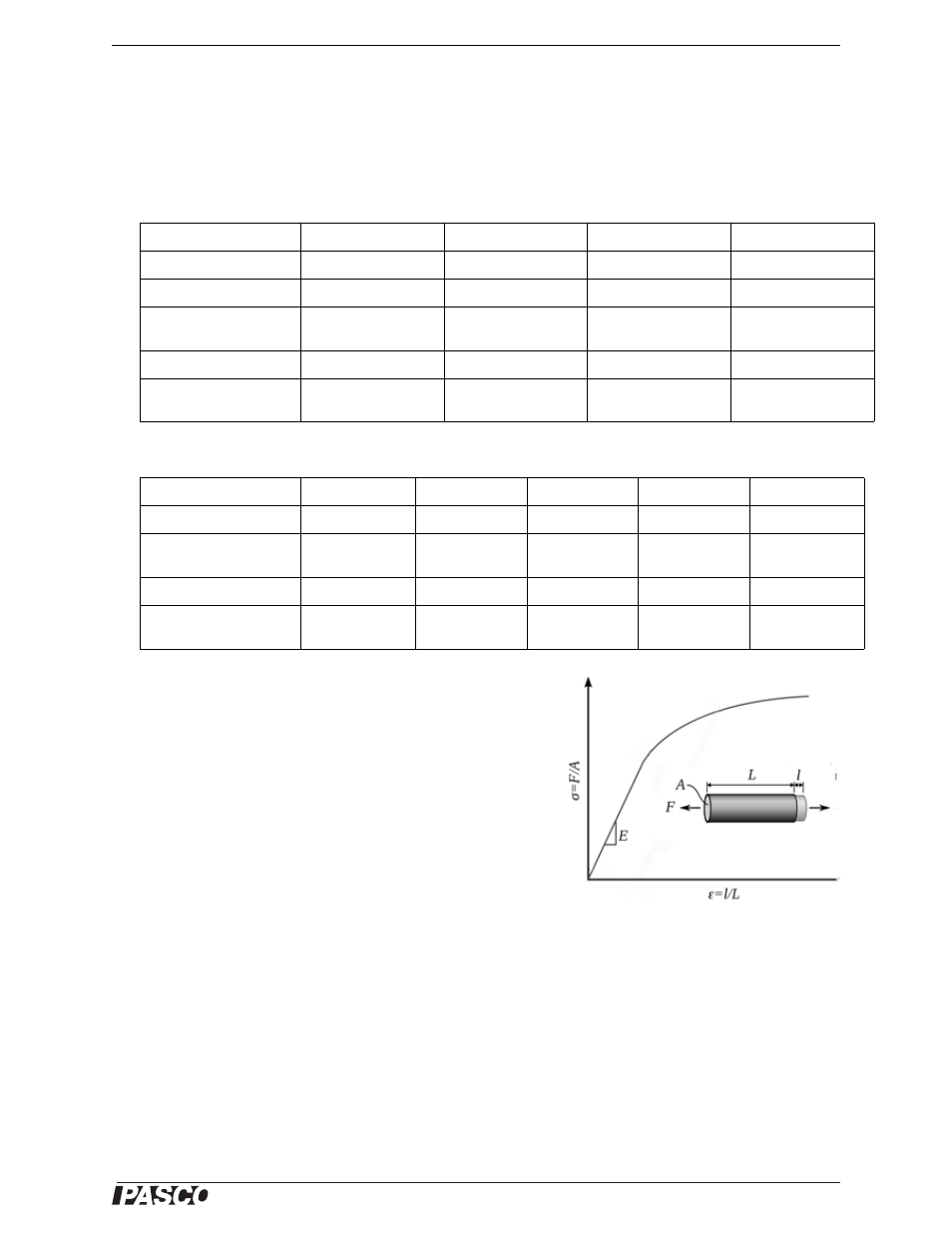

A stress-strain tensile test measures the amount of stretching force

applied to a sample of material, and the amount of stretch of a mate-

rial. Stress (

σ) is the ratio of force (F) per unit of cross-sectional area

(A). Strain (

ε) is the ratio of the change of length (l) compared to the

original length (L). A stress-strain curve is a graphical representation

of the load applied and the deformation of the sample. The curve var-

ies from material to material.

Ductile materials like metal have a linear stress-strain relationship up

to a point. The slope of the linear part of the stress-strain curve is

called “Young’s modulus” or the modulus of elasticity (E) and is a

property used to characterize materials.

Item

HIPS

nylon 6 (+ 15% glass)

ABS

polypropylene

Color code

orange

black

blue

white

Cross-sectional area

2.482 mm

2

2.482 mm

2

2.482 mm

2

2.482 mm

2

Tensile strength

23 MPa/

3410 psi

98 MPa/

14000 psi

47 MPa/

6800 psi

34 MPa/

4900 psi

Tensile elongation

40%

2.5%

20%

9%

Modulus of elasticity

2000 MPa/

280000 psi

2900 MPa/

420000 psi

2300 MPa/

380000 psi

1900 MPa/

239000 psi

Item

cold-rolled steel

annealed steel

aluminum

brass (thin)

brass (thick)

Cross-sectional area

0.303 mm

2

0.303 mm

2

0.303 mm

2

0.303 mm

2

0.506 mm

2

Tensile strength

620 MPa/

90,000 psi

300 MPa/

44,000 psi

145 MPa/

21,000 psi

430 MPa/

44,000 psi

430 MPa/

44,000 psi

Tensile elongation

none

42-45%

6%

25%

25%

Modulus of elasticity

200,000 MPa/

29,000,000 psi

200,000 MPa/

29,000,000 psi

69,000 MPa/

10,000,000 psi

117,000 MPa/

17,000,000 psi

117,000 MPa/

17,000,000 psi

Fig. 4: Stress-Strain curve