13 maintenance, 1 maintenance table, 0dlqwhqdqfh – Diamond Products FZ-4S User Manual

Page 37

FZ-4S

Maintenance

FZ-4S_e_0205.fm

Page 37

0DLQWHQDQFH

0DLQWHQDQFH WDEOH

Service the system within the indicated

intervals in order to ensure:

- Safety for the operator

- Optimum performance

- Optimum reliability at all times

8QFRXSOH

wall sawing system

prior to performing maintenance

work on the unit

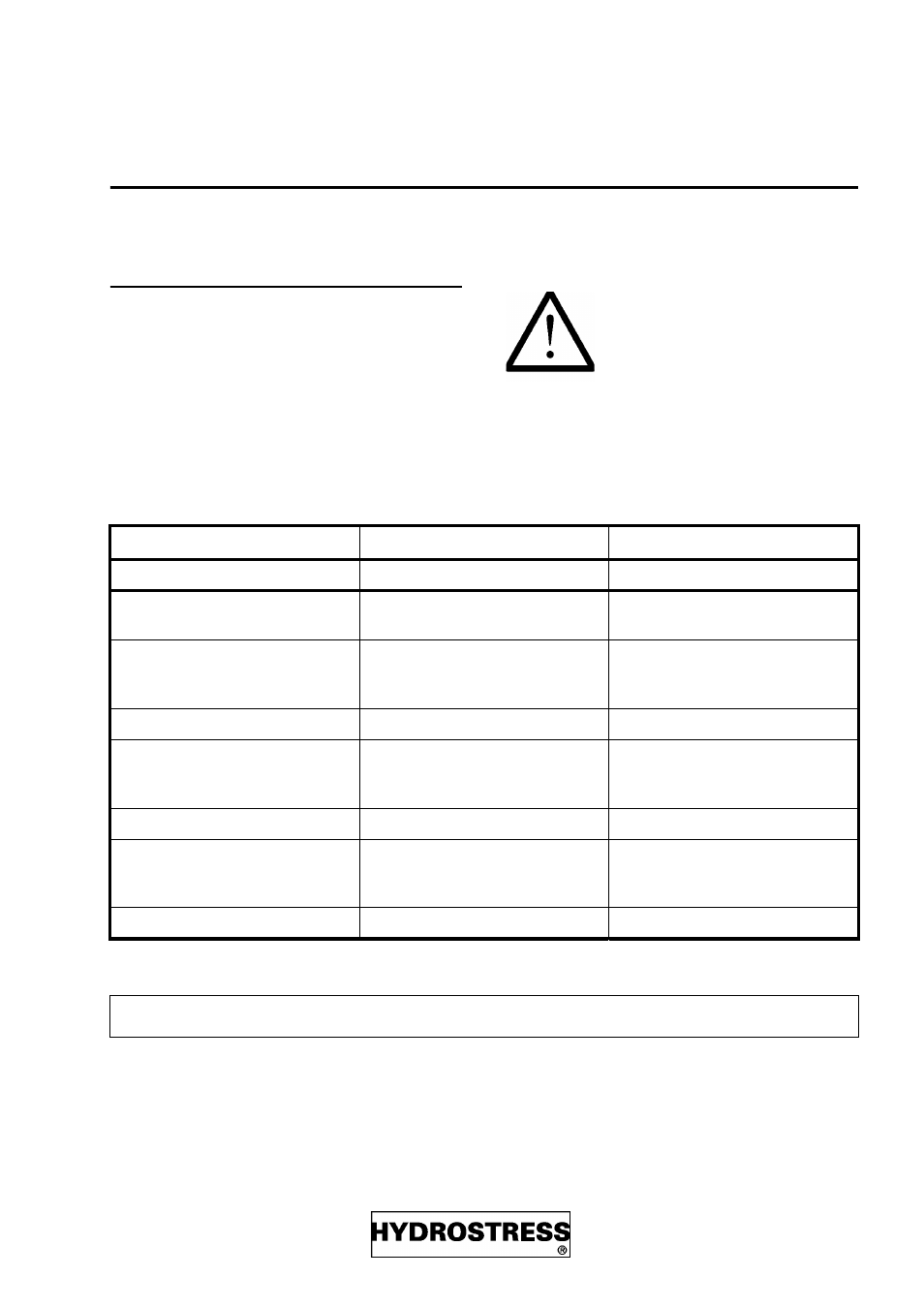

0DLQWHQDQFH LQWHUYDO

$FWLRQ

5HPDUNV

after first 50 h

Toothed wheel swivel arm oil change

Fill with 1 dl oil

weekly

Check prism guides for wear

Replace,

EHIRUH anchoring screws of

prisms touch the rail

weekly

Check couplings for

- leaks

- damage

Replace leaky or damaged couplings

weekly

Grease Y-slide guides grease nipple

2-3 grease injections

weekly

Check water couplings for

- leaks

- damage

Replace leaky or damaged couplings

annually

Change bearing housing grease

Fill with 600 g gear grease

annually

Major service

Must only be performed by

HYDROSTRESS or a HYDROSTRESS

authorised representative

every 100 h

Toothed wheel swivel arm oil change

Fill with 1 dl oil

Correct maintenance procedures are described on the following pages.