Pg20, Replacing the engine belt, Engine throttle screw – Diamond Products UDM User Manual

Page 23

3. Turn the belt adjustment shaft nut clockwise

to tighten the belt. Retest the tension and

readjust the nut as necessary to reach the

required tension setting. DO NOT exceed

the manufacturer’s setting.

4. Retighten the four nuts (under the frame) to

secure the alternator.

Replacing the Engine Belt

1. Loosen the nut on the four screws (under the

frame) securing the alternator to the frame.

2. Loosen the belt adjustment shaft nut. DO NOT

remove the nut.

3. Slide the alternator toward the engine to loosen

the belt.

4. Remove the belt from the alternator sheave.

5. Remove the two screws securing the hydraulic

pump to the pump mount. Holding the

hydraulic pump, move the pump over to

remove the coupling assembly from the pump

mount. Note: There is no need to remove any

hoses from the hydraulic pump.

6. Remove three of the four screws securing the

pump mount to the engine, the fourth must be

loosened.

7. Move the pump mount away from the engine

to provide access to the engine sheave.

8. With the pump mount loose, guide belt around

sheave, pull belt out through pump end.

9. Insert loop of new belt through rear opening

and out the side of pump toward generator.

Guide belt around coupler and into position on

the engine sheave.

10. Secure the pump mount to the engine.

11. Holding the hydraulic pump, place the coupling

assembly into the pump mount and fit the end

of the coupling assembly onto the engine

crankshaft.

12. Secure the hydraulic pump to the pump mount.

13. Retighten the coupling assembly setscrew to

secure the coupling assembly to the engine

crankshaft.

14. Loop and align the belt around the alternator

sheave.

15. Slide the alternator toward the side of the

machine (this will tension the belt slightly).

16. Turn the belt adjustment shaft nut clockwise to

tighten the belt. Test the tension and readjust

the nut as necessary to reach the required

tension setting. DO NOT exceed the

manufacturer’s setting.

17. Retighten the four nuts (under the frame) to

secure the alternator.

Engine

•

Let the engine cool down prior

to servicing the machine.

•

DO NOT service the machine

with the engine running unless

stated otherwise.

Refer to the engine manual and manufacturer for a

full maintenance schedule and additional

maintenance information.

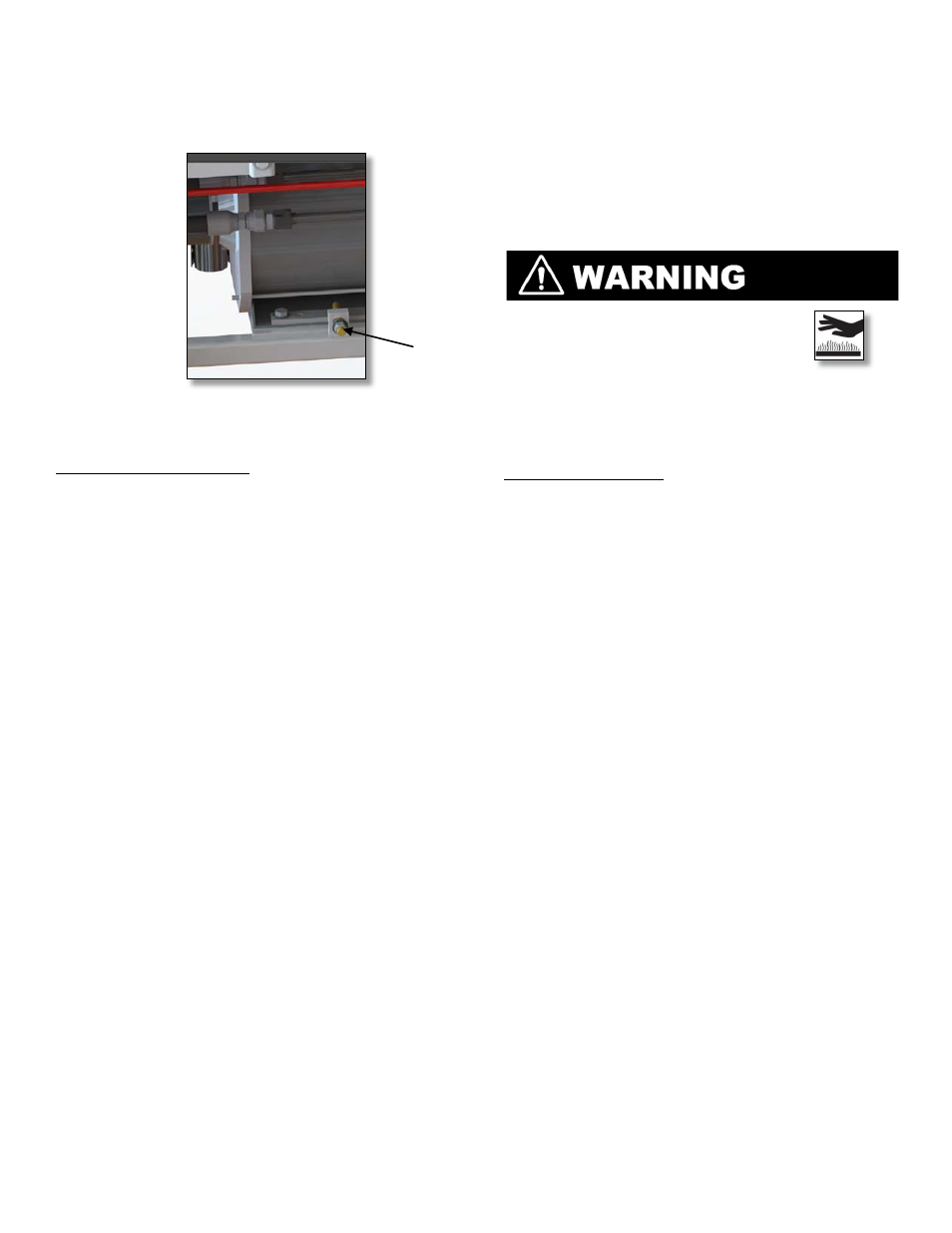

Engine Throttle Screw

The engine throttle screw (located at the top of the

engine) is factory set at 3,550 rpm. The screw

regulates the maximum no-load engine rpm.

Occasionally check the setting on the rear control

panel tachometer and adjust the screw as

necessary.

•

Turn off the engine.

•

Adjust the throttle screw.

•

Remove all tools from the area and restart

the engine. Check the engine rpm on the

rear control panel tachometer while at full

throttle.

•

Turn off the engine and readjust the throttle

screw as necessary.

Cleaning the Engine

•

Wipe down the engine’s exterior and oil

cooler daily/regularly to prevent high

operating temperatures. DO NOT spray the

engine with water to prevent engine

damage.

Storing

Complete the tasks listed below prior to storing the

machine for longer time frames:

•

Drain the water lines/hoses.

•

Drain all fluids.

•

Turn off all switches and controls (including

the master battery disconnects).

•

Clean and wipe down the machine to

remove dust, debris, and slurry from

components (especially fans).

•

Remove the battery and store in a proper

location, out of reach from children.

•

Store the machine in a dry area, protected

from outdoor elements, and out of reach

from children.

20