Pg16, Removing a stuck bit – Diamond Products UDM User Manual

Page 19

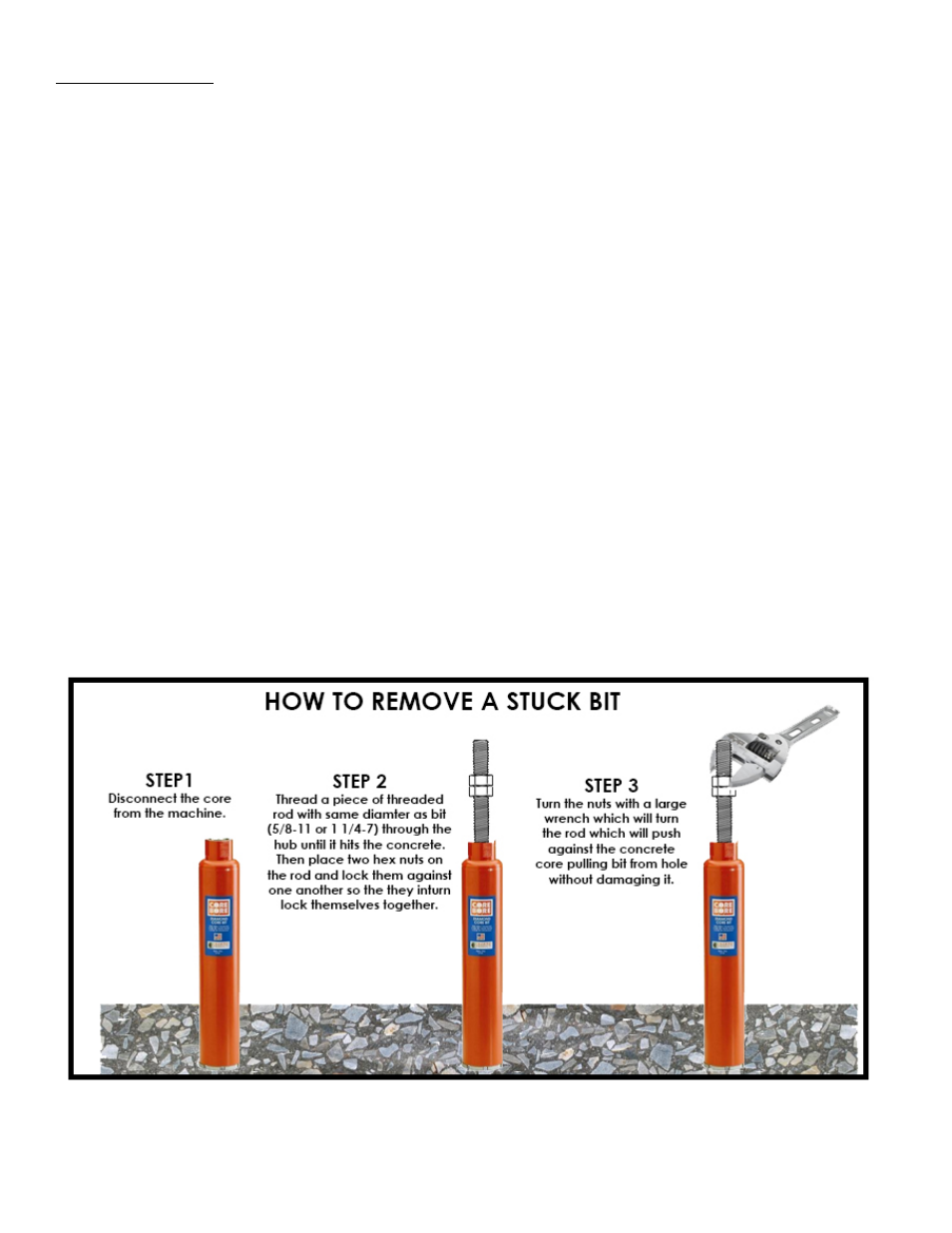

Removing a Stuck Bit

1. Release the Drill Down button or turn off the Auto

Drill switch. Press the Drill Up or Drill Down button

and Turbo button together to raise and lower the

bit to try and free it. Note: If the bit is not spinning,

turn the Drill Rpm cartridge on and off to try and

get the bit to spin (this will cause the drill motor

pressure to max out). If the bit is spinning, try to

keep it spinning while attempting to raise the bit.

Continue with step 2 if this attempt fails.

2. If the bit has moved toward the rear of the hole,

lower the rear legs slightly to attempt to realign the

bit. If the bit has moved toward the front of the

hole, raise the rear legs slightly to attempt to

realign the bit. Use the Drill Up and Drill Down

button while slightly raising and lowering the rear

legs or front mast in an attempt to find the break-

free position. Continue with step 3 if this attempt

fails.

3. Turn off the Drill Rpm cartridge.

4. Move the function switch to Start/Drive.

5. Turn off the engine.

6. Grasp the flats near the top of the spindle using

the wrench provided and turn counterclockwise

to disconnect the spindle shaft from the bit.

7. Move the machine away from the bit. Note: It may

be necessary to start the machine, lower the tires,

and raise the cylinder for proper ground

clearance.

8. Thread a piece of threaded rod (1-1/4-7) through

the hub until it contacts the concrete.

9. Place two hex nuts on the rod end and lock them

against each other.

10. Grasp both nuts using a wrench and turn to push

the rod against the concrete, which will pull the bit

out of the concrete.

NOTE: Inspect the bit for damages and clean or

replace as necessary.

16