Pg19, Hydraulic system, Changing the hydraulic oil – Diamond Products UDM User Manual

Page 22: Changing the hydraulic oil filter, Belt system, Tensioning the engine belt

Hydraulic System

•

Always use a piece of

cardboard or paper to check

for hydraulic fluid leaks. Keep all

body parts away from leaks

and/or areas that may eject hydraulic fluid.

Pressurized hydraulic fluid can penetrate the

skin, causing serious injuries. Seek medical

attention immediately!

•

Remove the core bit to reduce residual pressure

in the cylinder circuit prior to servicing the

machine.

Inspect the hydraulic hoses and fittings daily for

leaks. Replace damaged components

immediately.

Changing the Hydraulic Oil

An oil analysis program is recommended to

determine the oil’s condition and when to change

it. Along with the program; if the oil is kept clean,

dry, and has been operated at moderate

temperatures it may last for several years. With no

analysis program, change the oil every 200 hours.

1. Place an oil drain tray under the hydraulic

tank’s drain plug.

2. Remove the drain plug and drain the oil from

the tank. Replace the plug when completely

drained. Dispose of the used oil according to

city, state, and federal regulations.

3. Fill the tank to just below where the filler port

extends from the hydraulic tank. DO NOT overfill

as oil expands when hot. DO NOT contaminate

the oil to avoid damaging system components.

Use a high quality, petroleum based hydraulic

oil with the following properties:

a) Anti-wear

b) Low foaming

c) Rust and oxidation inhibitors

d) Wide temperature range

e) Fluid viscosity: 8-1,000 Centistokes (Cs)/(52-

4,600 SUS). Note: The machine is shipped

with an ISO 46 viscosity grade (8 Cs/52 SUS @

212°F/100°C and 46 Cs/210 SUS @

104°F/40°C).

4. Replace the oil cap and secure.

Changing the Hydraulic Oil Filter

Check the hydraulic filter gauge daily and replace

the filter once the gauge needle enters the red

range.

1. Place an oil drain tray under the hydraulic filter.

2. Unscrew the filter and hold it over the tray to

catch falling oil. Dispose of the used filter and oil

according to city, state, and federal

regulations.

3. Lightly oil the new filter’s rubber gasket with

clean oil.

4. Tighten the new filter according to the

directions on the filter.

5. Inspect the seal for leaks.

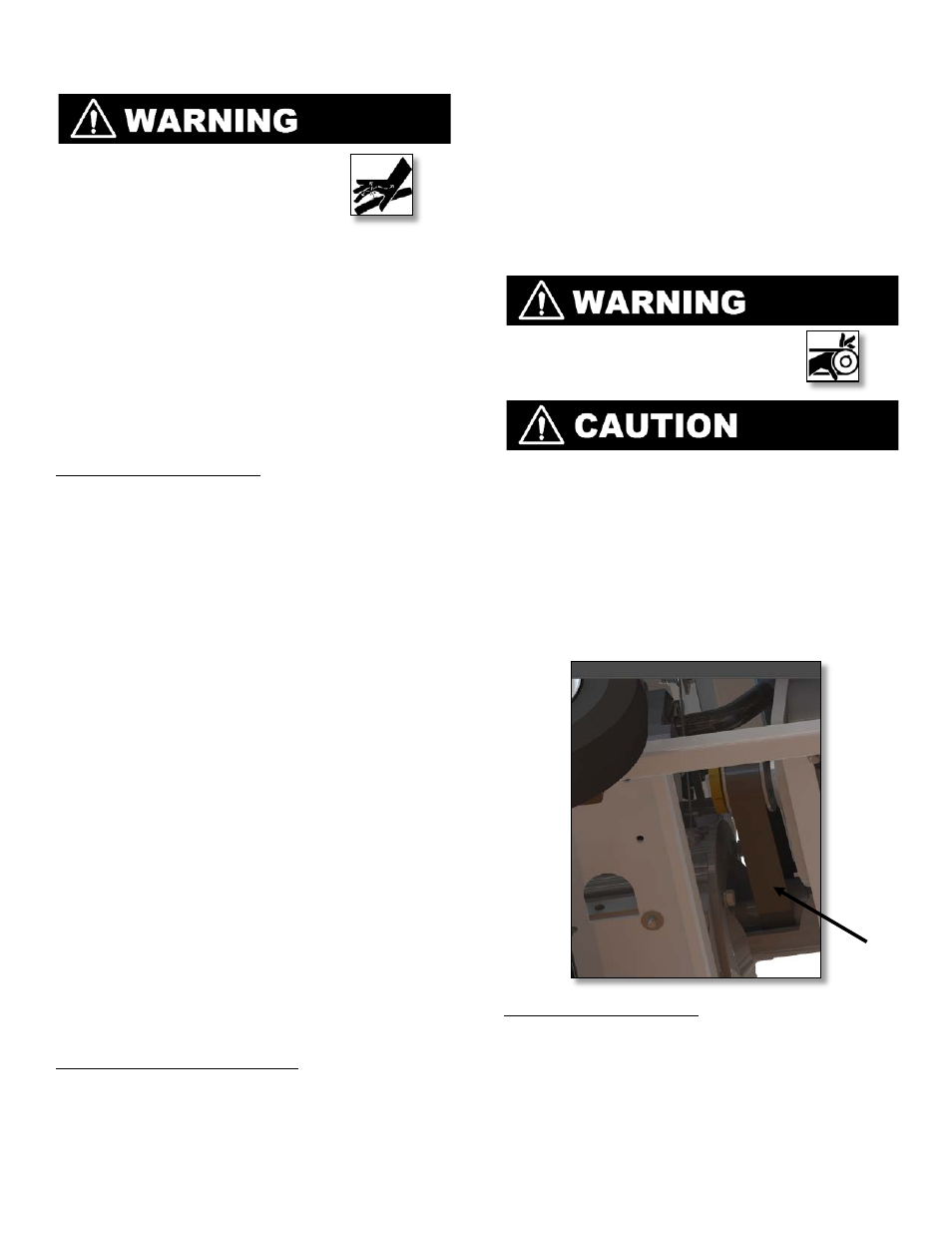

Belt System

•

Turn off the engine prior to

servicing the belts.

•

Always let the belts cool down prior to servicing

them.

Inspect the belts daily for fraying, stress cracks,

and/or breakage and replace immediately when

damaged. DO NOT exceed the manufacturer’s

belt tension settings when tensioning belts. Note:

Over-tensioning the belts may damage the engine

crankshaft. Under-tensioning the belts may cause

slippage, shorter belt life, and poor alternator

performance.

Tensioning the Engine Belt

1. Test the belt tension. Refer to Appendix C for

additional information and belt tension settings.

If adjustments are necessary, continue.

2. Loosen the nut on the four screws (under the

frame) securing the alternator to the frame.

19