Pg13, Inspecting the core bit, Core bit speeds – Diamond Products UDM User Manual

Page 16: Installing a core bit

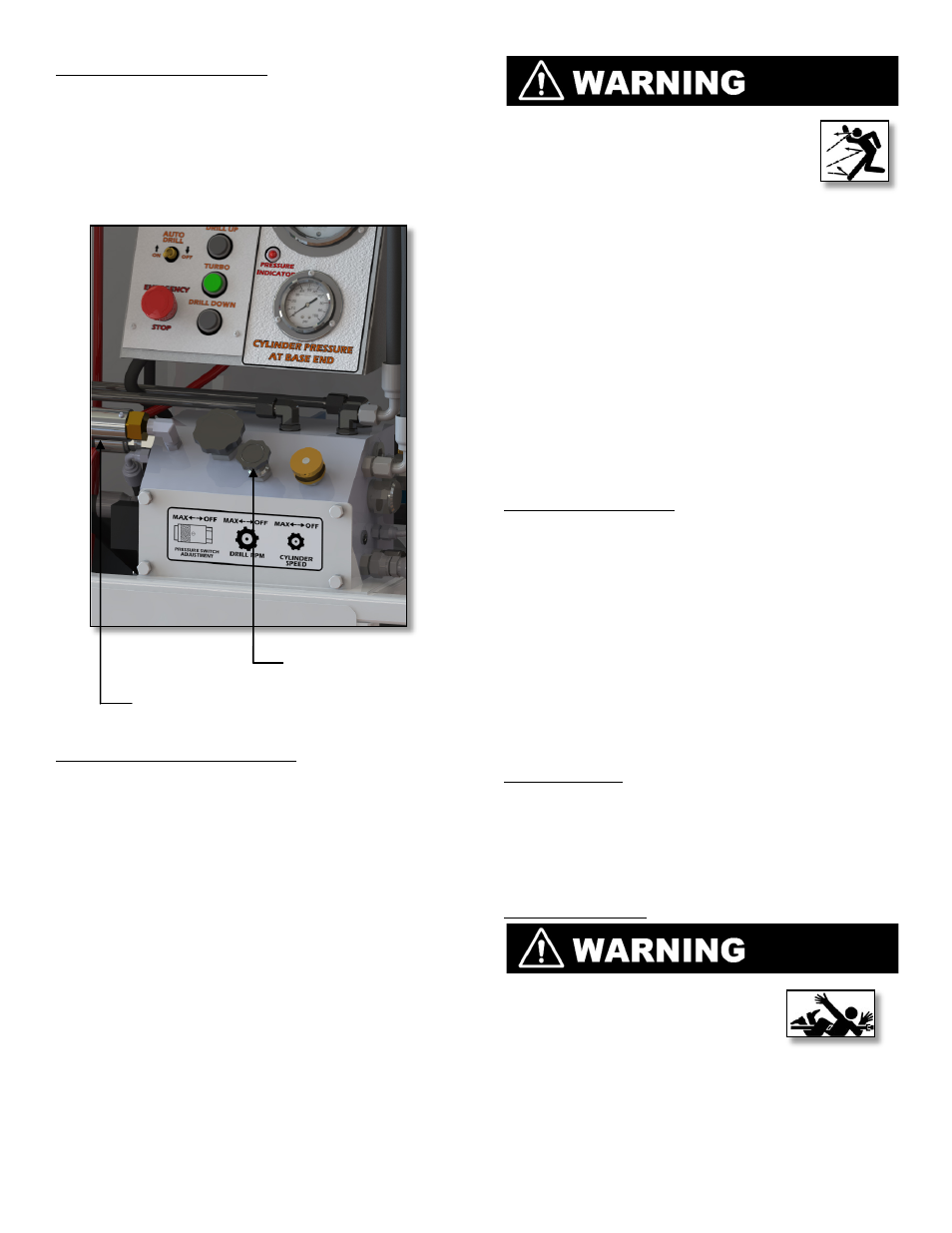

Drill Motor Pressure Switch

An adjustable pressure switch monitors the drill

motor pressure and will automatically shift the

cylinder to neutral (stops pushing) if it senses

the drill motor pressure rises above 1500 psi

(hard spots). The cylinder will then

automatically cycle ON/OFF as the drill works

through rebar or other hard spots.

Raising and Lowering the Drill

The DRILL DOWN, DRILL UP, and TURBO switches

are intermittent switches and must be held to

operate. Holding UP or DOWN and TURBO will

raise and lower the drill more rapidly for initial

positioning and quickly pulling a bit out of a

hole. These switches will not work when the

AUTO DRILL mode is selected.

Raising and Lowering Frame and Mast

To establish a more solid base, the pneumatic

tires are raised off the ground. This same action

places the vacuum base firmly on the ground.

Electric cylinders at the front and rear of the

machine are controlled by intermittent

switches located on the main side control

panel. The frame should be raised until the

front tires are just clear of the ground.

Independently adjusting the front and rear

controls allows slight leveling of the machine.

•

DO NOT exceed the core bit’s

maximum recommended

speed when drilling. Excessive

drilling speeds at first contact

with the concrete surface can

cause bit breakage, resulting in serious

injuries and/or death.

•

DO NOT use damaged core bits when

drilling to avoid harming yourself, others, or

the machine.

Diamond Core Bits

Using the proper core bit (size and type)

preserves the bit and improves drilling and

operator efficiency, resulting in lower costs.

Refer tofor

additional drilling and core bit information.

Inspecting the Core Bit

Inspect each core bit prior to installation and

discard all damaged bits. Inspect all core bits

for:

•

Cracks, nicks, and dents on barrel

•

Darkness and/or discoloration near

edge of bit

•

Uneven wear

•

Missing segments

•

Bent segments

•

Segment cracks

Core Bit Speeds

Refer to the chart on the machine for the

recommended core bit speeds when drilling.

DO NOT exceed the maximum recommended

drilling speed.

Installing a Core Bit

• Be extremely careful when

installing a core bit by hand

with the spindle shaft

activated to avoid

entanglement.

• Failure to properly secure the core bit to the

spindle shaft may cause the bit to loosen or fall

off the machine.

Cylinder Speed

Adjuster

Adjustable

Pressure Switch

13