Mix meter / pour test – Magnum Venus Plastech PUTTY UNIT User Manual

Page 31

Putty Unit Operations Manual

Rev. 07/2012

Page | 31

Mix Meter / Pour Test:

The same process and results that are used for testing the spray can be used for testing a pour system.

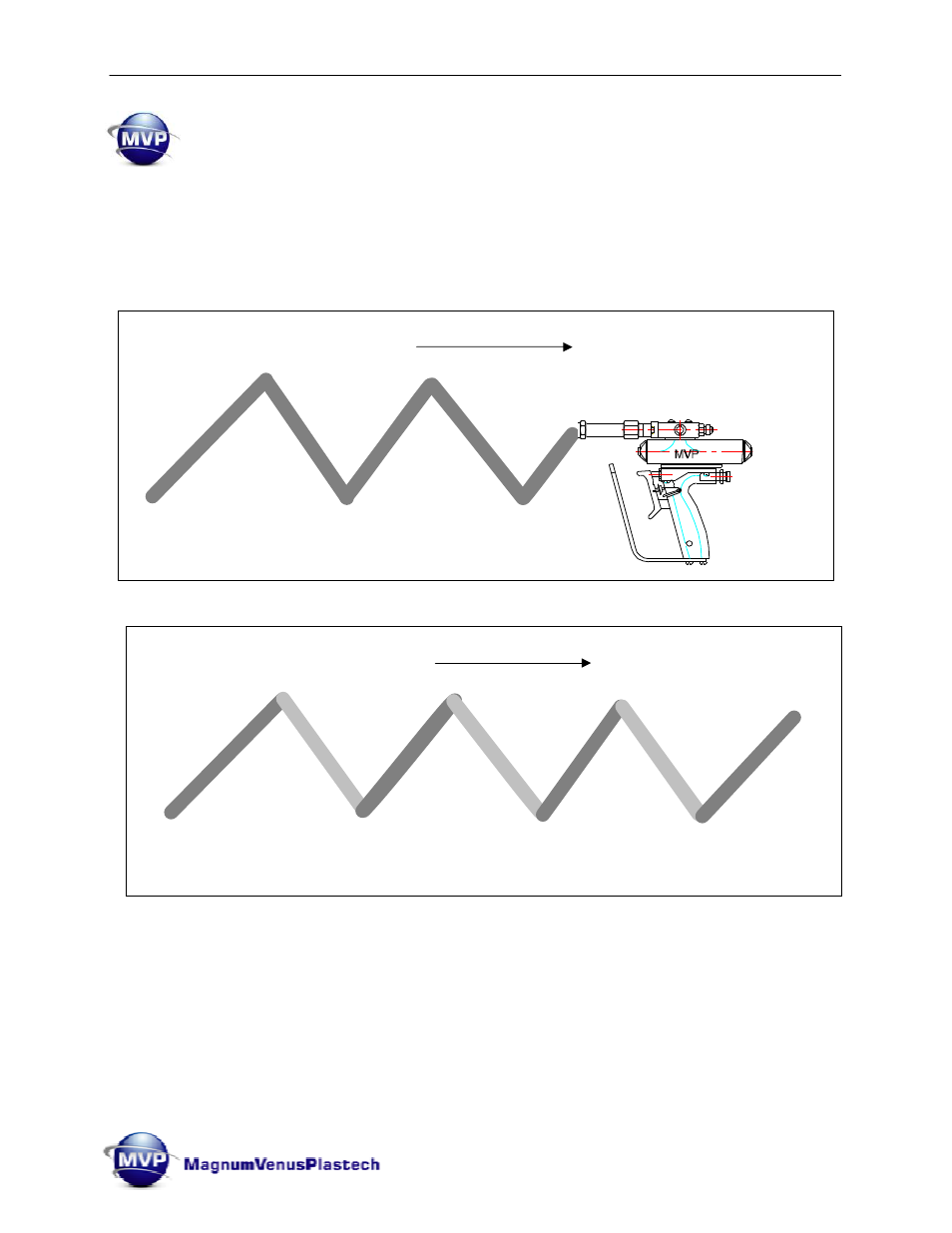

By pouring a bead of material in an up and down” zig zag” pattern then observing the results.

Note that depending on the length of the mixer there will be a delay in the metering issue

and where it appears on the pattern.

Test 1

Result 1:

Material delivered at the top and bottom of the stroke is not curing or curing more slowly than the material

delivered in the middle of the up- and down-stroke, see figure above.

Indicates: Low/no catalyst at top (T) and bottom (B) of the pump stroke.

Probable Cause: There is no or improper accumulation effect in the catalyst system. Normally

this is only a problem at high pressures.

Solution: Check to be sure you are using the proper catalyst hose, with or without core. Install a

catalyst accumulator if needed. Check for a restriction in the catalyst system.

Start Pour Test

Direction of gun travel

End Pour Test

B

B

B

T

T

Start Pour Test

Direction of gun travel

End Pour Test

B

B

B

B

T

T

T