Magnum Venus Plastech PUTTY UNIT User Manual

Page 21

Putty Unit Operations Manual

Rev. 07/2012

Page | 21

5. Ram should begin to lift, check for hoses catching or kinking

6. Allow ram to go to full “up” position (clearance for drum)

7.

Once ram is to maximum up position, tape the Piston Boot (60531-1) the round piece of plastic (use

plastic boot as a template to make more before installing) to the top of the barrel piston. Make sure

that the round hole in the center of the plastic piston boot is centered with the opening at the bottom

of the barrel piston.

NOTE: If the 55-gallon (200 liter) drum has a plastic liner it is helpful to prevent the liner from being

pushed down into the drum. Use the ring from the drum top to hold the liner in place or tape the

liner to the outside of the drum. Inspect the drum for dents and damage, using a dented or

damaged drum can damage the piston seals and cause leaking.

8. Slide 55-gallon (200 liter) drum of Putty onto the unit and center drum to the barrel piston.

9. Recheck Piston Boot (60531-1) as the opening must be lined up with intake of pump

10. Open ball valve located at the top of the barrel piston; this will allow air trapped between the barrel

piston and the putty to escape. (see Fig. 19)

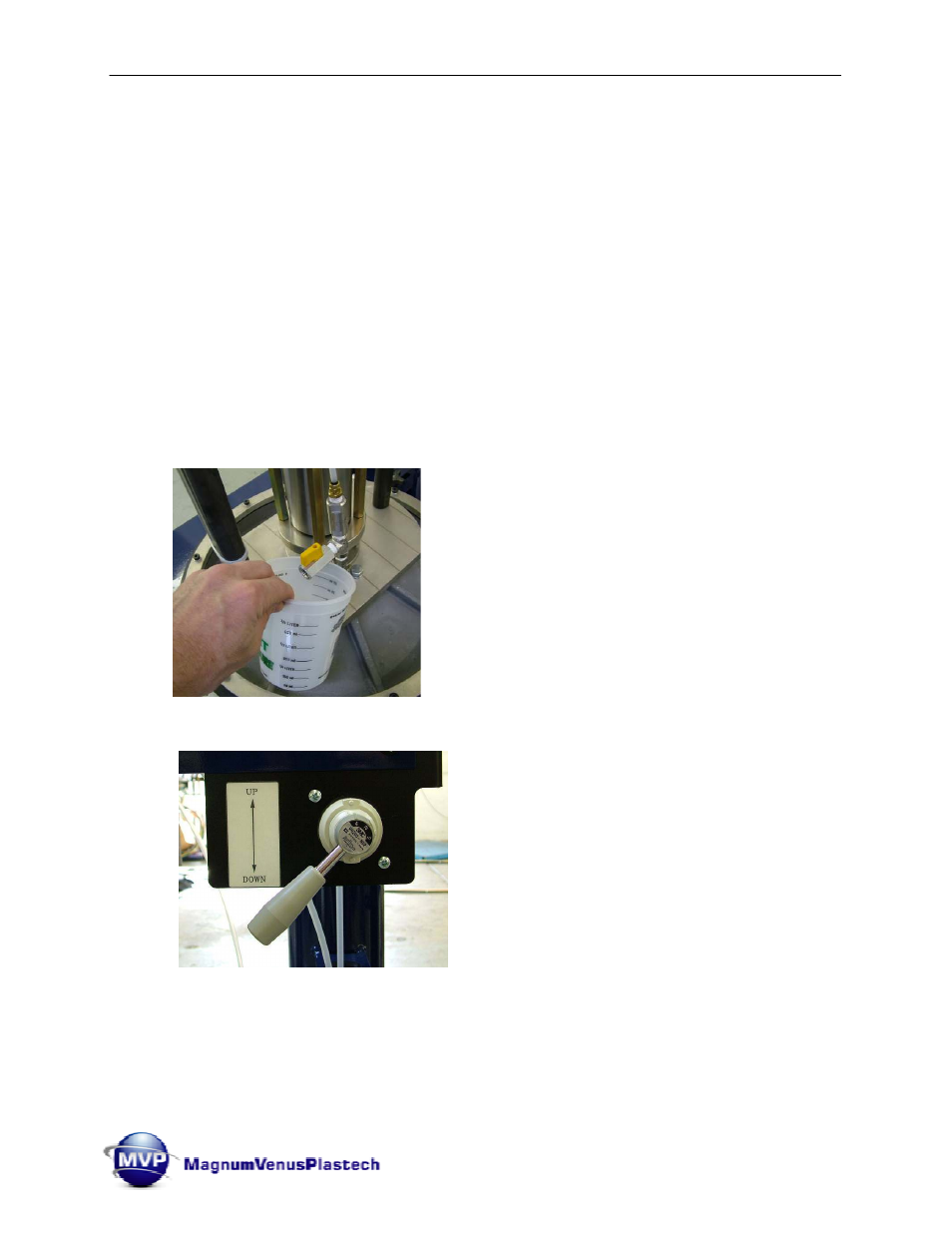

Fig. 19

11. To lower barrel piston down into the drum, push rotary valve (06275) handle to down position (see Fig. 20).

Fig. 20

12. Once barrel piston has started into Putty drum, slowly increase Airlift regulator pressure 40 to 60 psi.

NOTE: Allow time for air to be pushed out of the ball valve (06276) at the top of the barrel piston.

13. Once barrel piston has come to a complete stop and a small amount of material starts to come out

the ball valve close the ball valve at the top of the barrel piston.

14. Remove the Mixer assembly or Nozzle from the front of the gun mix chamber.