Liquid Controls SCAMP User Manual

Page 14

14

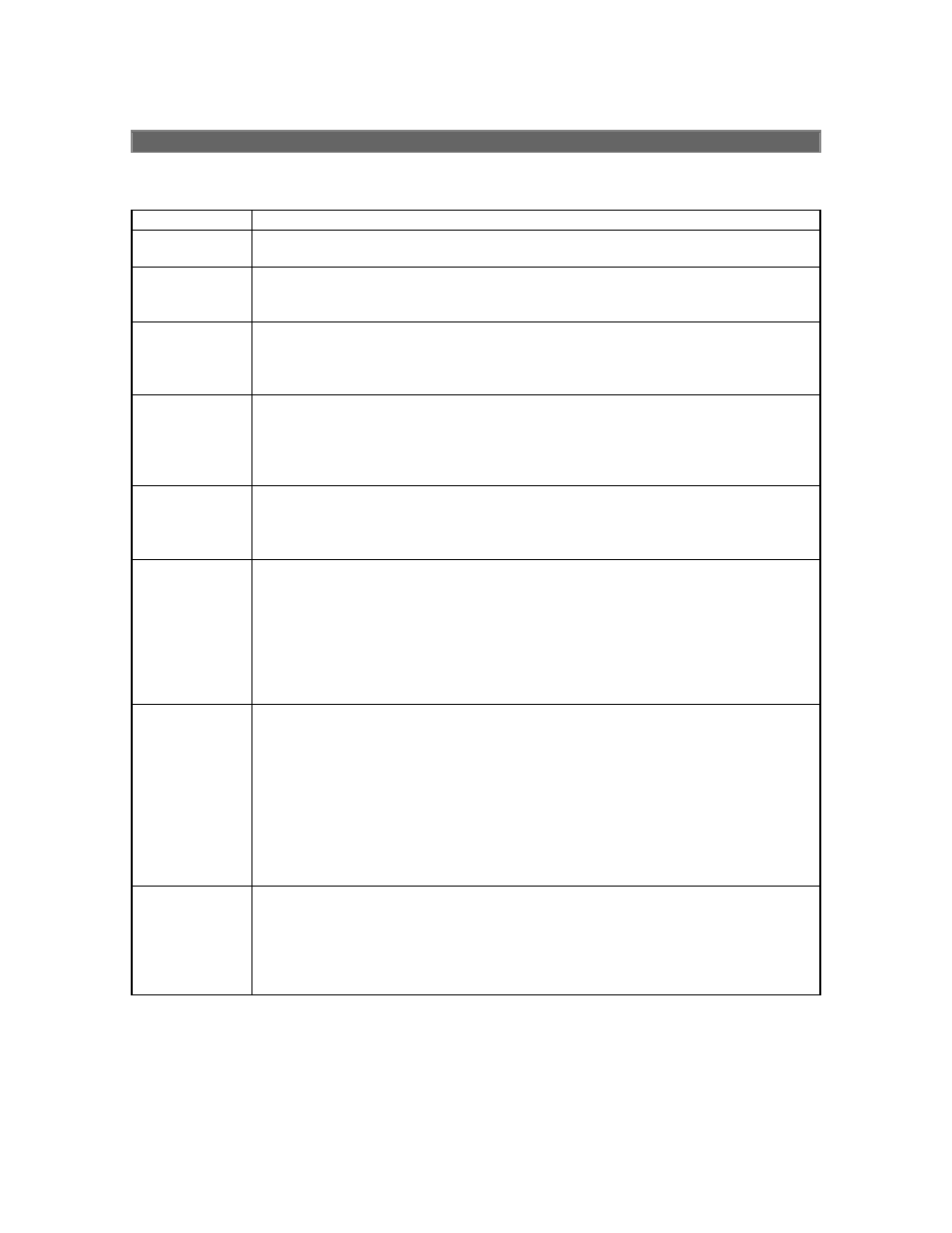

ERROR MESSAGES

Disabling Errors

Error Code

Description

E100

The program code space of the SCAMP has been corrupted and needs to be

reloaded. Contact Liquid Controls on how to proceed.

E110

An excessive number of pulser reversals have occurred. Once flow has

stopped, ensure that the pulser is connected properly to the SCAMP and try

running flow again. If the problem persists, the pulser may need to be replaced.

E111

Scalar adjustment range error. The quadrature scalar was adjusted by

linearization or temperature compensation so that it represents a k-Factor less

than 4.000. Ensure that the linearization tables were set up correctly and that

the temperature compensation parameter was entered correctly.

E120

Adjacent flow rate points in the linearization table have percent errors with a

difference greater than 0.250%. Find the two points whose difference is out of

range and use a spare point to fill the gap. If all points have been used, a re-

analysis of the data will need to be performed so as to ensure no two adjacent

flow rate points have a difference greater than 0.250%.

E121

Incomplete linearization table setup. A flow rate was set for a point, but the

percent error field was not set. Find the point that is causing the error and

either disable the point by entering an invalid flow rate, e.g. 04002, or set the

percent error field for the point.

E130

An error occurred while reading from the non-volatile data storage device.

Attempt to clear the error by performing a “Clear All” operation. This is done by

moving the “0/1” jumper to the “0” position, setting the Function Switch and all

Data Switches to “0”, and pressing the Data Entry pushbutton.

WARNING: After a successful “Clear All” operation, it will be necessary to

re-enter all calibration data. You may want to record all accessible data

before performing the “Clear All” to minimize the re-calibration effort.

E131

An error occurred while writing to the non-volatile data storage device. Try

setting the field again. If the field cannot be set successfully, attempt to clear

the error by performing a “Clear All” operation. This is done by moving the “0/1”

jumper to the “0” position, setting the Function Switch and all Data Switches to

“0”, and pressing the Data Entry pushbutton. If the problem persists, the

SCAMP unit will need to be replaced.

WARNING: After a successful “Clear All” operation, it will be necessary to

re-enter all calibration data. You may want to record all accessible data

before performing the “Clear All” to minimize the re-calibration effort.

E140

The current temperature is out of range for the volume compensation type

selected. Verify that the temperature probe is returning the correct temperature

by moving the "0/1" jumper to the “0” position, setting the Function Switch to

“C”, and reading the displayed temperature. If the temperature value is

incorrect, replace the temperature probe. If the problem persists, the SCAMP

unit will need to be replaced.

NOTE: The last Disabling Error Code (error codes greater than or equal to 100) may be

viewed by setting the “0/1” jumper to the “0” position, the Function Switch to the “E”

position, and observing the LED display. The last error code can be deleted

(recommended only after resolution of the error) by setting all the Data Switches to “0”,

and pressing the Data Entry pushbutton with the Function Switch in the “E” position.