Liquid Controls SCAMP User Manual

Page 13

13

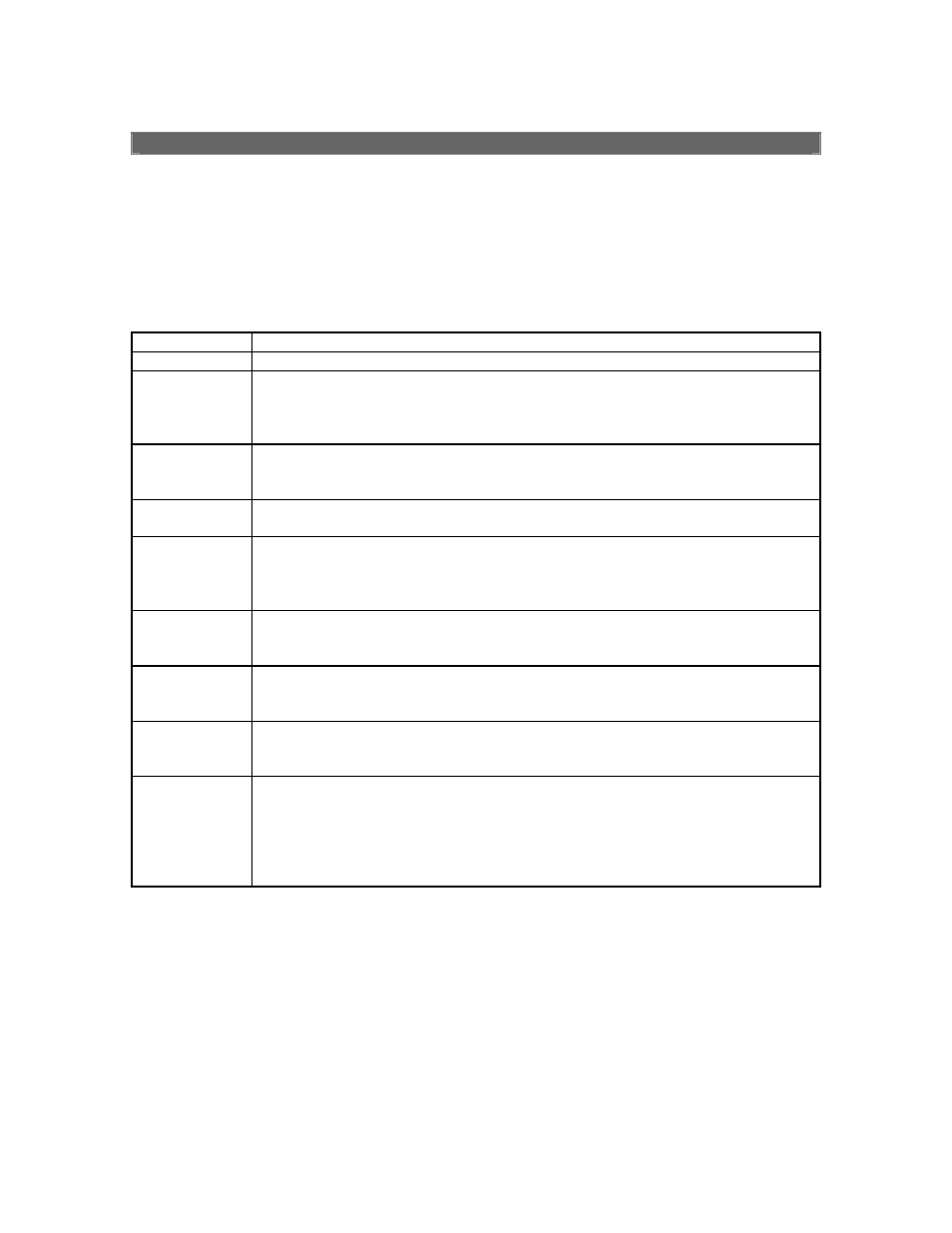

ERROR MESSAGES

SCAMP provides error codes that appear on the LED display located on the SCAMP

circuit board. Following is a list of all possible error codes along with a description of the

error and suggested corrective actions. The errors are classified according to two levels

of severity: non-critical errors; and disabling errors. Non-critical errors are not listed in

Function Switch position “E”, and will not interrupt operation of SCAMP. Disabling errors

are listed in Function Switch position “E”, and will prevent further operation of SCAMP.

Non-Critical Errors

Error Code

Description

E0

No error has occurred.

E1

Range error. The value read when the Data Entry pushbutton was pressed is

outside the valid range limit for the field selected. Ensure that the Data

Switches represent the value desired, focusing on the decimal point adjuster

switch (sw1), and attempt setting the value again.

E2

An individual data switch returned a value greater than 9. Ensure that each

Data Switch is firmly “clicked” into its position and try entering the value again.

If the problem persists, the SCAMP unit will need to be replaced.

E10

An attempt was made to calibrate the A to D converter at the 128.6 ohm resistor

value before calibration was done at the 100.0 ohm resistor value.

E20

The linearization point has not been setup and is disabled. NOTE:

Linearization data is optional and need not be set for each (or any) of the

16 available points. In the case of unused points, the E20 error message

should be disregarded.

E21

The flow rate being set for a linearization point is already being used by another

linearization point. Each linearization point being used must contain a unique

flow rate.

E22

An attempt was made to set the percent error field of a linearization point but

the flow rate has not been set for the point. Set the flow rate for the point first,

and then re-enter the percent error field.

E30

A write to flash was attempted with the “LOCK” jumper in the “LOCK” position.

Move the “LOCK” jumper out of the “LOCK” position and try setting the field

again.

E40

The temperature volume compensation parameter has not been set. Set the

Data Switches to the desired temperature volume compensation parameter for

the compensation type selected and press the Data Entry pushbutton. NOTE:

Temperature Volume Compensation parameters need not be set for

unused Compensation Tables. In such cases, the E40 error message

should be disregarded.