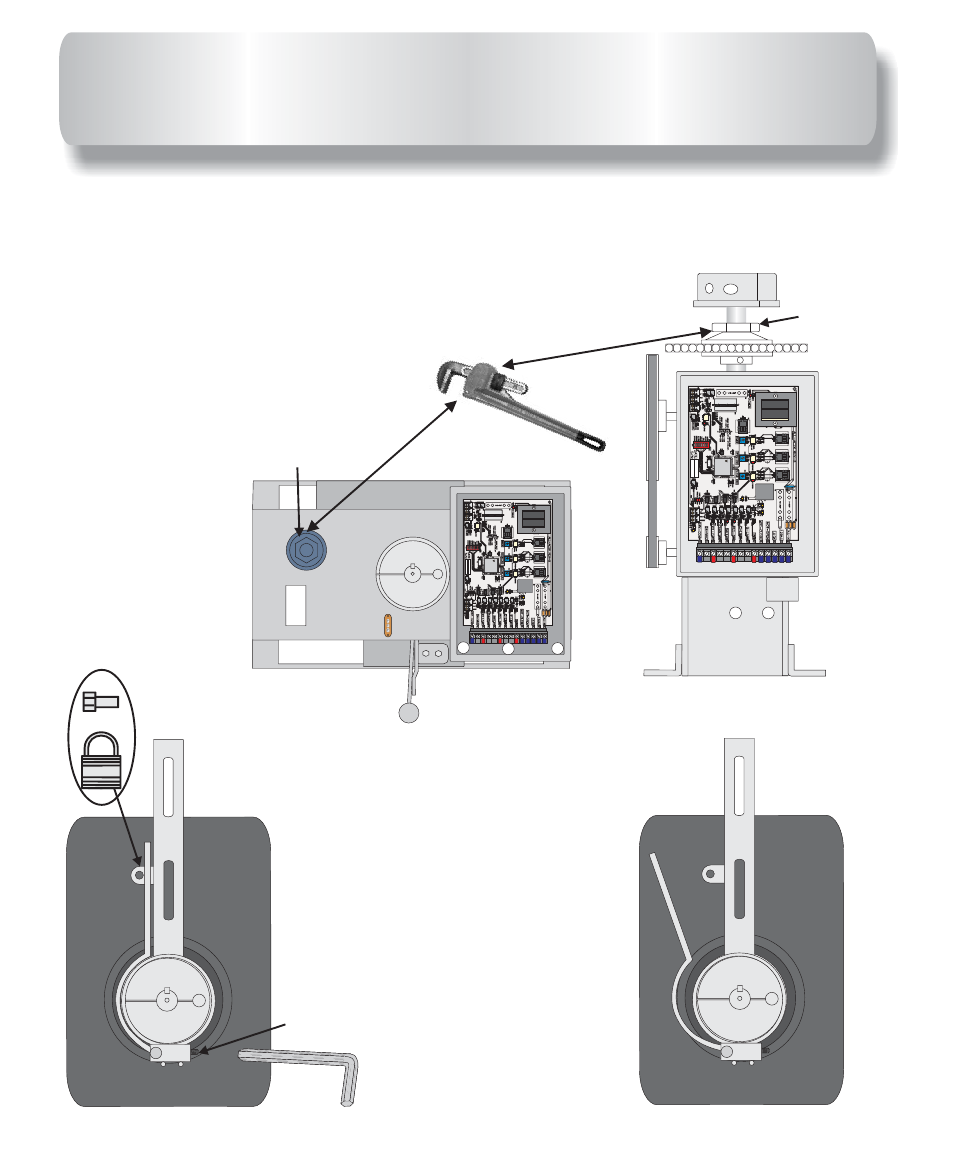

Torque and arm adjustment, Emergency release on sw-300, Torque limiter and arm adjustment – Controlled Products Systems Group AOMSW300 User Manual

Page 12

19

O UR

N

38

6

B

S

3

1

3

O UR

N

38

6

B

S

3

1

3

O UR

N

38

6

B

S

3

1

3

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

-----------------------OPEN------------------------

PHILIPS

P87C554SBAA

Cd2399

TIG0505A

PHILIPSPHILIPS

ONO

N

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ONO

N

514

GDE

ONO

N

514

GDE

O

N

ON

514

GDE

ON

514

GDE

00 uF

00 uF

2200 uF

2200 uF

2200 uF

2200 uF

2200 u

2200 u

3

2

1

O UR

N

38

6

B

S

3

1

3

O UR

N

38

6

B

S

3

1

3

O UR

N

38

6

B

S

3

1

3

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

-----------------------OPEN------------------------

-----------------------OPEN------------------------

PHILIPS

P87C554SBAAP87C554SBAA

Cd2399

TIG0505A

PHILIPS

ON

514

GDE

O

N

O

N

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ON

514

GDE

ONO

N

514

GDE

ON

514

GDE

00 uF

00 uF

2200 uF

2200 uF

2200 uF

2200 uF

2200 u

2200 u

MASTER

20” Pipe wrench

Torque limiter

adjusting nut.

Torque limiter

adjusting nut.

The torque limiter is shipped loose (not adjusted). You must use

a 20” pipe wrench to adjust the large torque limiter nut on the operator

as shown in the images below.

Tighten torque limiter nut until arm does not slip when the

operator is running.

Also run gate and grab gate at mid cycle to make sure torque

limiter will slip. This is an important adjustment, so please take your

time and do it right.

SW-300

SW-350

Top view

Side view

TORQUE LIMITER AND ARM

ADJUSTMENT

Allen wrench

Arm adjusting

screw

ARM ADJUSTMENT:

ARM QUICK RELEASE:

Use a pad lock or

a bolt to hold the arm lever in closed

position. With the arm lever closed

tighten the arm adjusting screw as tight

as possible.

To release the

arm with the quick release, simply

remove the bolt or padlock from the arm

lever and open it. Opening the arm lever

will allow you to manually open the gate.