Controlled Products Systems Group 10463283 User Manual

Page 9

P a g e 9

Ja nua ry , 2 00 7

6 2 0 /6 40 O pera t or A nd

6 2 4B LD C ontr ol Pa ne l Ins talla tio n M a nual

P

REPARE

THE

F

ORMS

FOR

THE

C

ONCRETE

S

LAB

AND

C

ONDUIT

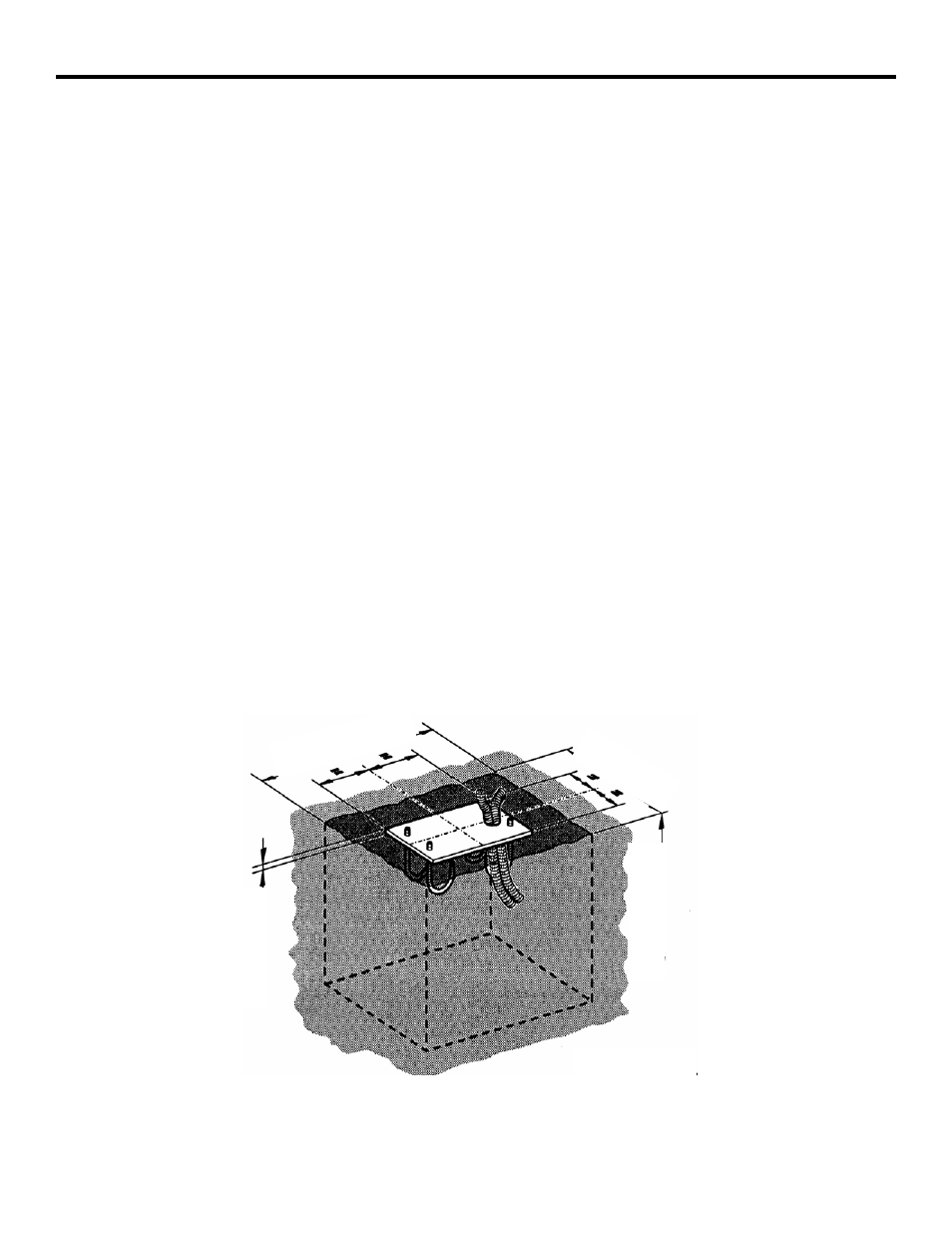

You need to set the concrete forms to provide a cement

footing that is a minimum of 18 by 18 in. (46 by 46 cm)

and that is poured a minimum of 18 in. (46 cm) below

the ground level or just below the frost line, whichever

is greater (see Figure 4). (Your soil conditions will also

affect the size of the cement footing.) To help prevent

rust, the top of your cement footing should be above

ground level.

Within the form boundaries you must locate the

electrical conduit so that it will protrude through the

foundation plate (the plate is provided as an option) and

above the top of the foundation plate about

1/2 in. (1.3 cm).

The exact placement of the conduit is determined partly

by the foundation plate you use and more importantly

by the access holes in the bottom of the operator

cabinet (see Figure 5). If you choose to supply your own

foundation plate, be sure to use steel that is 3/8 in. (1

cm) thick for the plate and be sure to provide a hole

large enough to accommodate your two electrical

conduits, one for high-voltage wire and one for low-

voltage wire. In addition, your foundation plate needs

four 1/2-in. (1-1/4 cm) anchor bolts that extend at least

6-1/2 in. (16-1/2 cm) into the cement footing. The

anchor bolts should be positioned to match the holes in

the bottom of your operator's cabinet.

1/

4”

24”

15”

18

”

After the concrete is poured in the forms and before it

sets, place the foundation plate in the cement so that the

top of the plate is level and flush with the top of the

cement.

Allow the concrete to set a minimum of two full days

before you mount the operator cabinet.

With the key provided, open the operator's panel door

and lift the door away from the cabinet. It may be

necessary on your model of operator to disconnect the

wiring to the fan on the panel door to allow you to more

easily handle the heavy cabinet.

Set the operator cabinet on the foundation plate, aligning

the holes in the bottom of the cabinet with the bolts and

conduit protruding above the foundation plate. Bolt the

cabinet to the foundation plate and cement footing. If

necessary, reconnect the wiring to the fan on the panel

door.

Before connecting the main power to your barrier, you

must remove the vent screw on the hydraulic power pack.

Midway along the top, left edge of the hydraulic power

pack is a 3 mm Allen screw. Remove it now. Failure to

remove the screw can result in erratic operation of the

barrier beam. Do not throw the screw away in case you

ever need to transport the barrier unit or its hydraulic

power pack.

Figure 4. Recommended Concrete Form Dimensions