Controlled Products Systems Group 10463283 User Manual

Page 12

P a g e 1 2

Ja nua ry , 2 00 7

6 2 0 /6 40 O pera tor And

6 2 4B LD C ontr ol Pa ne l Ins tal la tion M a nual

A

DJUST

THE

H

YDRAULIC

P

RESSURES

Now that the beam is attached, re-engage the hydraulic

operation of the barrier by rotating the Manual Release

key clockwise.

Send an opening activating signal to the barrier. The

signal should open the barrier. If it does not open,

increase the pressure of the opening bypass valve (the

green valve) by turning the screw clockwise in small,

1/8- turn increments until the beam does open.

Test the closing of the barrier in the same way. If the

beam fails to move in the closing direction, then

increase the pressure of the closing bypass valve (the

red valve) by turning the screw clockwise in small

increments until the beam does close.

Remember that you should set the bypass pressure

valves so that the beam works with the least pressure

necessary. It is a safety feature of the barrier that the

beam should apply no more than about 33 lb (15 kg)

force against any obstacle it might encounter.

WARNING! For maximum safety to people and

property, use photo eyes and other non-contact

reversing devices in addition to adjusting the

bypass pressure valves to the minimum settings.

I

NSTALLING

THE

E

MERGENCY

B

YPASS

S

OLENOID

AND

ANTI

-

VANDALISM

VALVE

(230V

AC

M

ODELS

O

NLY

)

WARNING! Turn the main power off before you

make any electrical connections or set any

switches inside the control panel box.

The emergency bypass solenoid automatically

disengages the hydraulic system of the barrier beam

when the main power is not available. This allows the

barrier to be raised by hand so that people and vehicles

can safely pass during power interruptions and failures

without having to manual release the barrier.

Note: Once the emergency bypass solenoid has

disengaged the hydraulic system and once you

have raised the beam by hand, you cannot lower

the barrier beam until the power is restored or

by using the manual release key.

If you are installing the optional emergency bypass

solenoid, you must first turn off the main power and

disengage the hydraulic system by using the Manual

Release key.

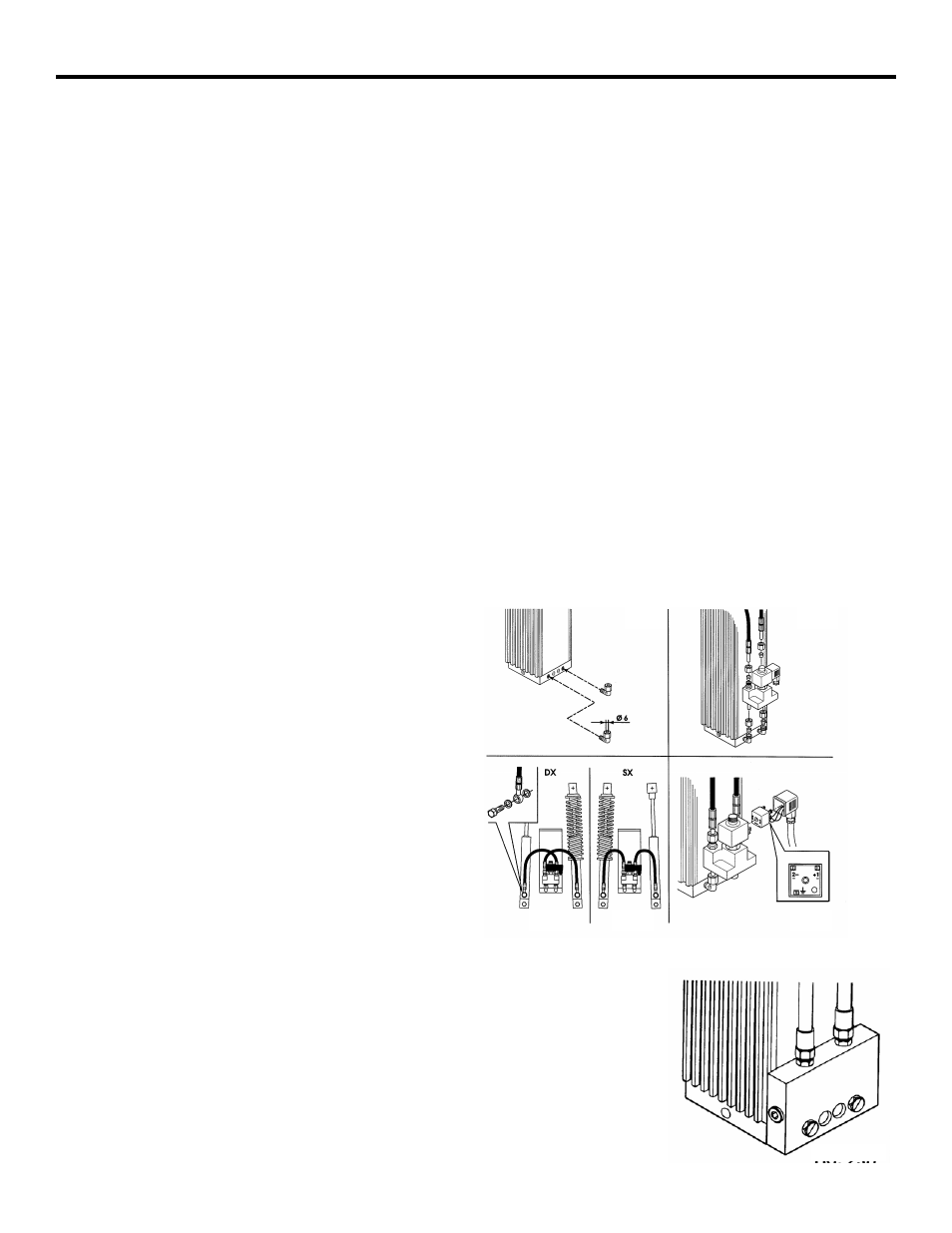

Then you disassemble the hydraulic lines between the

pistons and the operator so that you can install new

hydraulic pipe fittings.

After installing the new pipe fittings, install the

emergency bypass solenoid as shown in figure ()

After connecting the solenoid, you need to connect the

hydraulic lines between the operator and the pistons.

How you connect the lines depends on the orientation

of your barrier installation (see Figure 11).

Finally, connect the solenoid to your main power line

so that it can sense when power is or is not available

(see Figure 11).

Re-engage the hydraulic system with the Manual

Release key so that you can test the installed solenoid.

To test the solenoid, turn off the power to the barrier. If

the solenoid works, you should be able to raise the

beam but not lower it after raising it. You should be

able to lower the beam only after turning the power

back on.

Install the anti-vandalism

valve with the instructions

that are provided with it in

it’s packaging.

Figure 11. Emergency By-Pass Valve

and the Anti-Vandalism Valve