Controlled Products Systems Group 10463283 User Manual

Page 11

P a g e 1 1

Ja nua ry , 2 00 7

6 2 0 /6 40 O pera t or A nd

6 2 4B LD C ontr ol Pa ne l Ins talla tio n M a nual

C

HECK

THE

C

OMPRESSION

S

PRING

The compression spring should be adjusted so that it

holds the beam in any position that it is placed while in

manual mode. (Manual mode is discussed on page 7

shown in Fig. 2)

Move the beam by hand to a half-opened position. The

beam should stay there when you remove your hand.

Note: All compression spring adjustments should

be made with the beam in the vertical (open)

position.

If the beam drifts toward the closed position, turn the

adjuster nut (shown in Fig. 10) clockwise to tighten the

compression spring.

If the beam drifts toward the opened position, turn the

adjuster nut (shown in Fig. 10) counterclockwise to

loosen the compression spring.

.

Note: Proper adjustment of the spring will

counterbalance the beam. This will allow the

minimal pressure setting necessary to move the

beam in a smooth movement.

NOTE: The spanner wrench shown in figure 10

is NOT sold by FAAC or needed top make this

adjustment.

A

TTACH

THE

B

ARRIER

B

EAM

WARNING! Do not install the barrier in such a way

that the beam moves within 2 feet (610 mm) of a

rigid object.

Before you attach the barrier beam, be sure you have

disconnected the barrier from hydraulic operation by

means of the Manual Release mechanism (turning the

key counterclockwise).

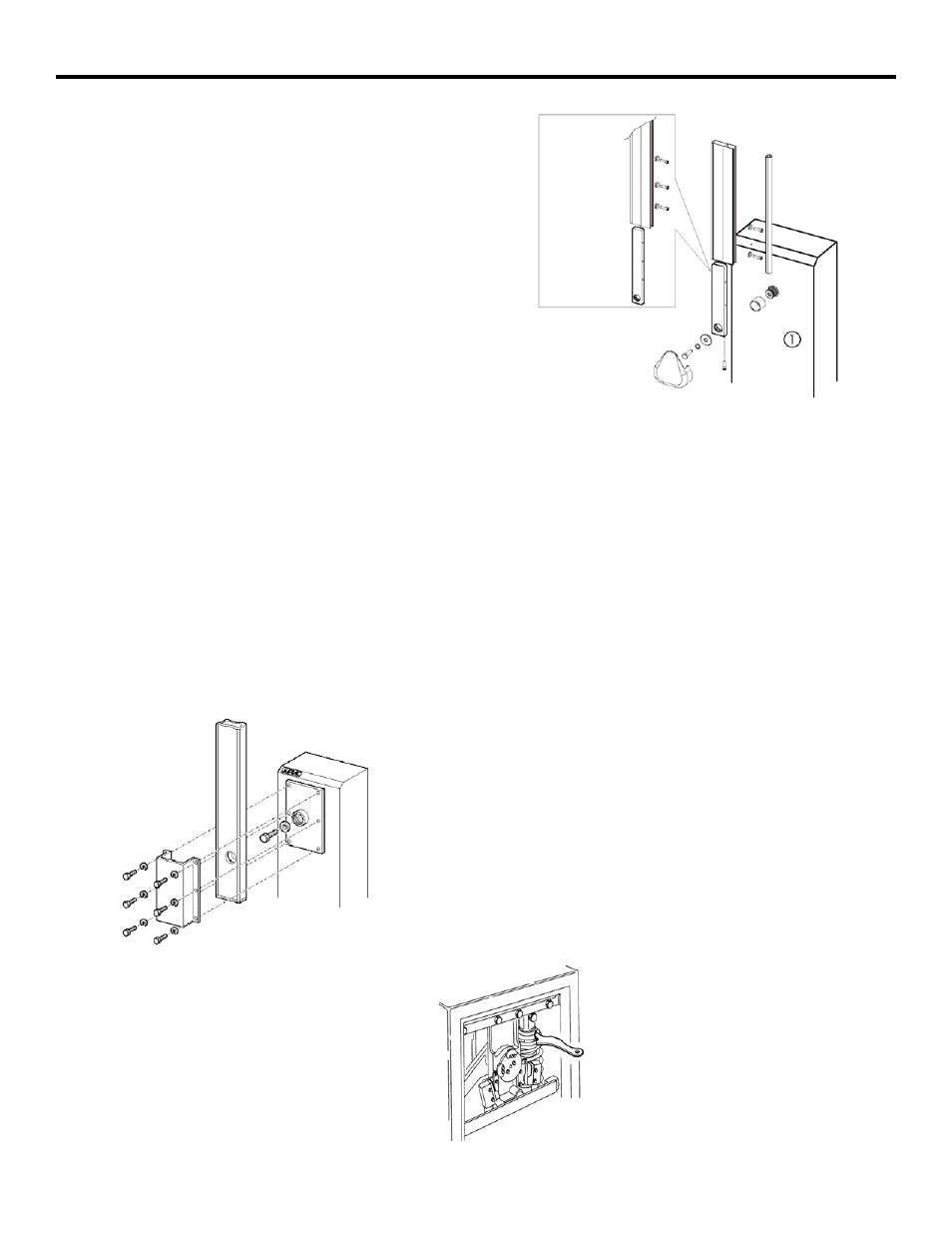

Next you attach the beam to the operator cabinet with

the beam in a vertical position. See Figure 8 if you are

attaching an aluminum beam to a model 620

operator ,see Figure 9 if you are attaching an aluminum

beam to a model 640 operator. (Wooden beams require

additional sandwich plates).

C

HECK

THE

M

ECHANICAL

S

TOPS

First, be sure the hydraulic operation of the beam is still

disengaged (the Manual Release key should be turned

counterclockwise). Next, move the beam by hand from

the fully opened position (vertical) to the fully closed

position (horizontal) and back to the fully opened

position. If the positions are not perfectly vertical and

perfectly horizontal, then adjust the mechanical stops

as necessary (see Figure 7) using a 17mm socket

wrench. The jam nut must be loosened first and

tightened last.

615/620

Figure 8. Beam Attachment 620 (Aluminum Beam)

Figure 9. Beam Attachment 640 (Aluminum Beam)

Figure 10. Adjuster Nut

640