Controlled Products Systems Group 10463283 User Manual

Page 13

P a g e 1 3

Ja nua ry , 2 00 7

6 2 0 /6 40 O pera t or A nd

6 2 4B LD C ontr ol Pa ne l Ins talla tio n M a nual

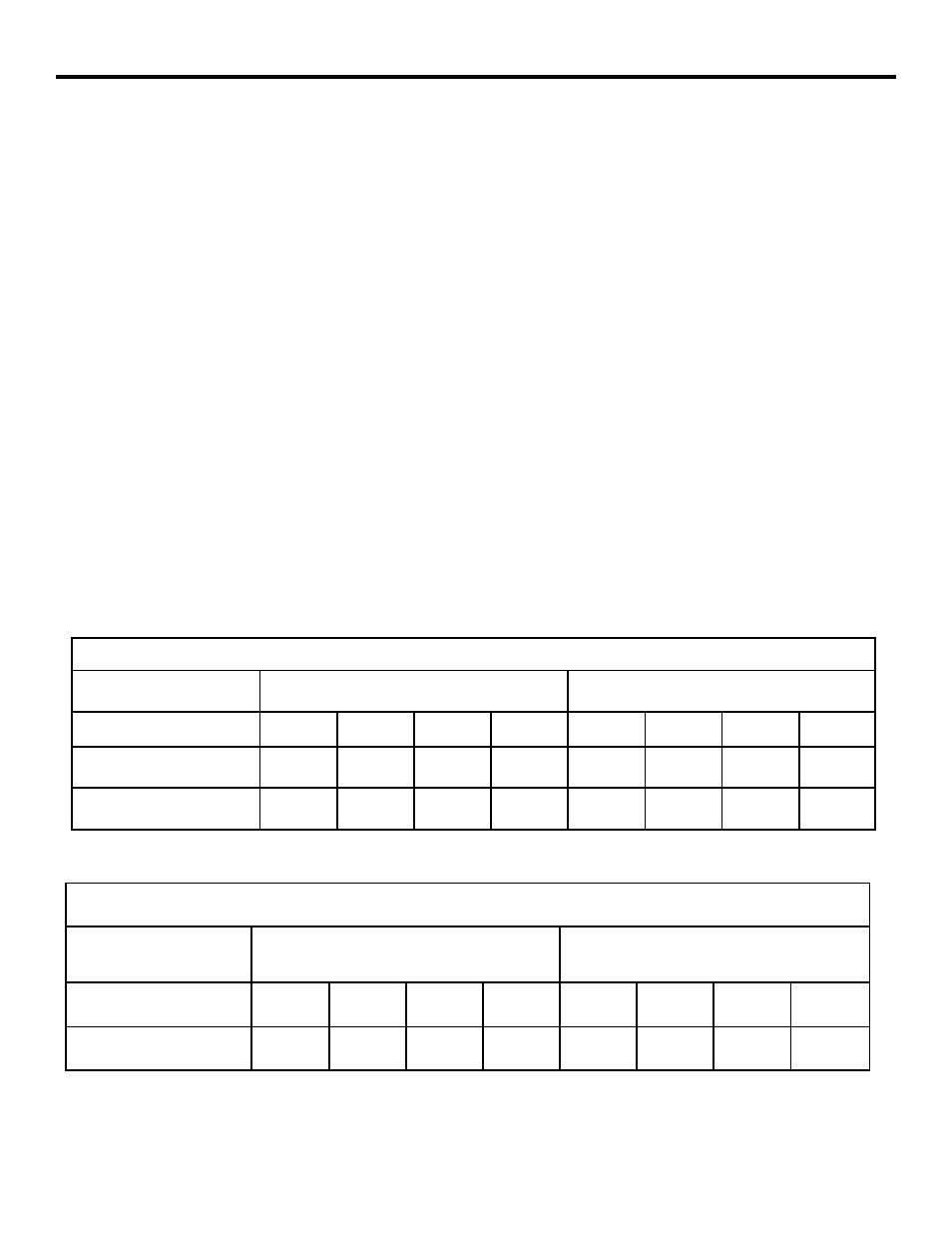

Rigid Beams: Part Numbers of Compression Springs for Various Lengths

Beam and Required

Spring

620 Barrier Systems

640 Barrier Systems

Redwood Beam, ft

8–10 12–14 16 NA 16–18

18–20 20 NA

Rigid Aluminum

Beam, ft (m)

6 (2)

8 (2 1/2)

10 (3)

13 (4)

13 (4)

16 (5)

20 (6)

23 (7)

FAAC Part No. for

Compression Spring

7210855 7210695 7210705 7210885 7210735 7210745 7210755 7210805

Beam and Required

Spring

620 Barrier Systems

640 Barrier Systems

Skirted Aluminum

Beam, ft (m)

6 (2)

8 (2 1/2)

10 (3)

13 (4)

13 (4)

16 (5)

20 (6)

23 (7)

FAAC Part No. for

Compression Spring

7210695 7210715 7210735 7210745 7210795 7210805 7210815 7210825

Skirted Beams: Part Numbers of Compression Springs for Various Lengths

Unbolt the piston with the compression spring from the

rocker arm. Then very carefully unscrew the cap holding

the compression spring by hand to the left to remove

the spring from the piston. Remove the spring from the

piston.

NOTE: Hold the bottom of the piston cylinder to

keep the piston rod from sliding out of the

cylinder.

Install the correct compression spring by placing it over

the piston and screwing it into place with adjusting cap.

Then bolt the piston to the rocker arm and reinstall the

steel cross member. Re-engage the hydraulics by

turning the Manual Release key clockwise.

Be sure to recheck the tension of the compression

spring before you turn on the main power to the

operator. Then be sure to adjust the hydraulic

pressures.

C

HANGING

THE

L

ENGTH

OR

T

YPE

OF

B

ARRIER

B

EAM

WARNING! Do not install the barrier in such a

way that the beam moves within 2 feet (610 mm)

of a rigid object.

Changing the length or type of the beam requires

installing a different balancing compression spring.

Make sure you have the correct compression spring

(designed for a particular weight of beam).

The installer is responsible for making sure that the

compression spring is the correct spring for the barrier

beam.

The following tables show which springs are designed

for various beam types and lengths. To check for the

part number of the compression spring in your barrier,

check the tag attached to the spring previously

installed.

If it is necessary for you to replace the spring in a

cabinet with another compression spring, do the

following. First, turn off the main power to the operator

and then open the cabinet panel. Turn the Manual

Release key counterclockwise. Then move the beam by

hand to the fully opened position.