Chapin 2553E User Manual

Warning, Parts, piezas, pièces, Nozzle/extension

6-4626

Shut-off Handle

Mango de cierre

Poignée du robinet

Hazard: Improper use or failure to follow instructions can result in explosive failure causing

serious eye or other injury.

For safe use of this product you must read and follow all instructions.

Do not leave a pressurized sprayer in the hot sun. Heat can cause pressure build-up. Do not store

or le

ave solution in tank after use. Always wear goggles, gloves, long sleeve shirt, long pants and full

foot protection when spraying. Never use any tool to remove pump if there is pressure in sprayer.

Never stand with face or body over

top of tank when pumping or loosening pump to prevent eject-

ing pump assembly and/or solution from striking and injuring you. Never pressurize sprayer by any

means other than the original pump. Do not attempt to modify or repair this product except with

original manufacturer’s parts. Never spray flammable materials or heat, pressure, or gas produc-

ing chemicals. Always read and follow manufacturer’s instructions before use with this sprayer

as some chemicals may be hazardous when used with this sprayer.

WARNING!

Sk-1113-1

Parts, Piezas, Pièces

6-6136

Hose

Manguera

Tuyau

Repair Parts Kit Gaskets and Seals (not included),

Juego de piezas de reparación, empaquetaduras y juntas (no incluido)

Kit de pièces de réparation, joints et garniture d’étanchéité (non inclus) 6-1925

Printed in U.S.A., Impreso en E.U.A, Imprimé aux U.S.A.

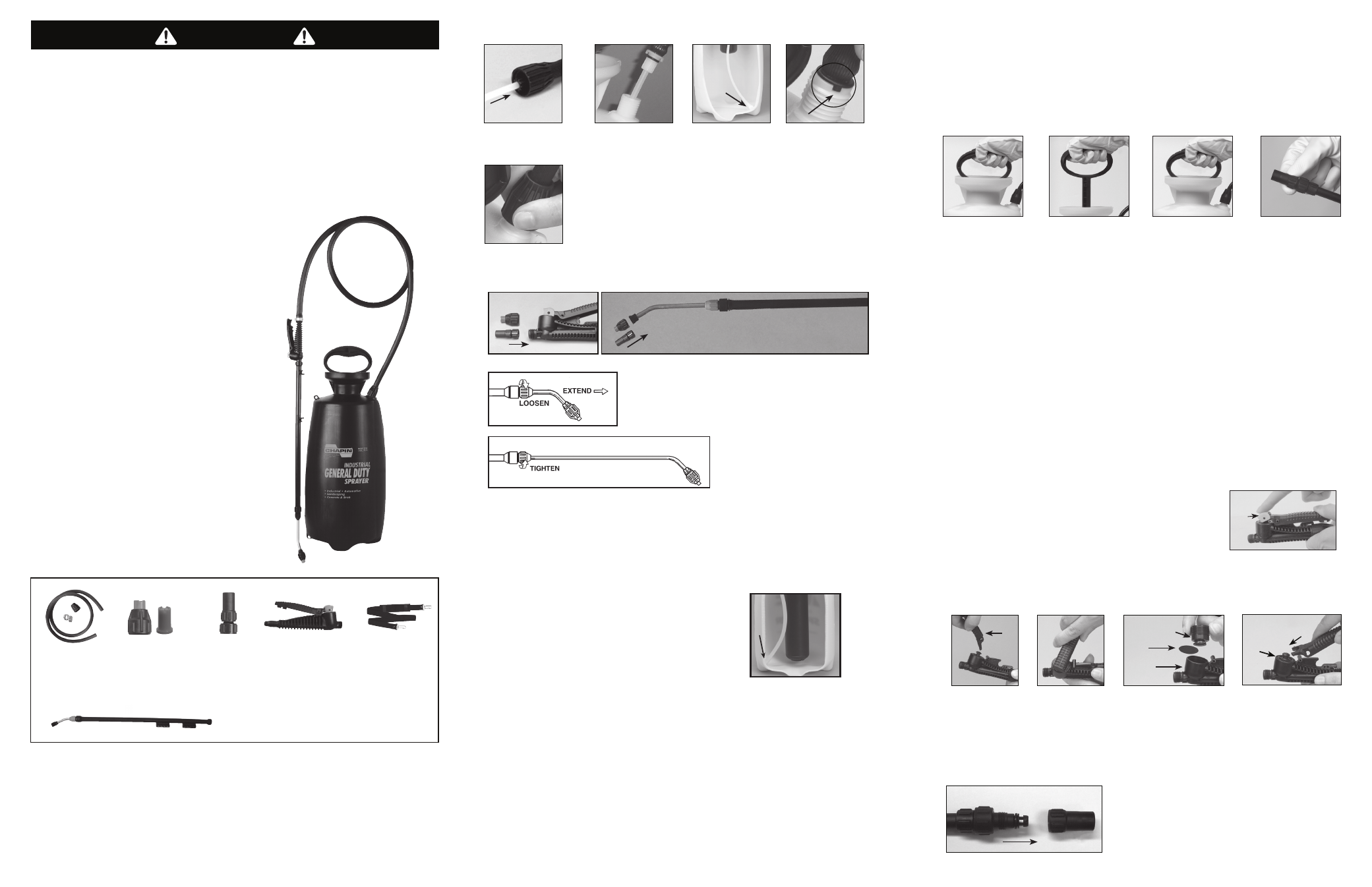

2. Nozzle/Extension

1) Do: Check tightness of hose nut to be sure hose is securely attached to the tank outlet.

2) Do: Inspect hose for deterioration, cracks, softness, or brittleness. If any of these conditions are found, replace hose

before using. Replace with original manufacturer’s parts only.

3) Do: Remove pump (see Filling, Pressurizing and Spraying Instructions), inspect interior and exterior of tank for signs

of deterioration of body and bottom. Any sign of deterioration indicates possible tank weakening and could result in

explosive bursting under pressure. If any of these signs are found, discard tank immediately and replace. Do not attempt

to patch leaks, etc., as this could result in serious injury.

4) Do: Follow Filling, Pressurizing and Spraying Instructions, except use water only.

5) Do: Pump plunger 10-20 strokes and inspect for leaks.

6) Do: Direct shut-off away from you and open to make sure discharge is not clogged.

7) Do: If unit passes this test, release pressure (see Pressure Releasing Instructions), empty tank, and proceed with Filling,

Pressurizing and Spraying Instructions.

4. Pre-Use Check

5. Filling

1) Do: Turn pump handle counterclockwise and remove pump

2) Do: Prepare spray solution following all directions and safety warnings on chemical label.

3) Do: Fill tank to no more than the proper gallon marker. Do NOT: overfill to accommodate pump.

4) Do: Check pump to make sure that no grass or dirt is stuck to barrel. Replace pump in tank and tighten securely.

6. Pressurizing and Spraying

8. Care, Storage and Maintenance

1) Do: Rinse tank thoroughly with water only, empty, refill with water. Follow Filling, Pressurizing and Spraying

Instructions, except pump unit only 8-10 strokes.

2) Do: Open shut-off and allow water to run through discharge assembly.

3) Do: Release pressure (Follow Pressure Release Instructions), remove pump and empty sprayer.

4) Do: Store sprayer tank upside down, with pump removed, in a warm dry location.

5) Do: Periodically oil pump by dropping 10-12 drops of light oil down pump rod through opening in cover.

6-6003

Nozzle

Tobera

Buse

2-1085-100 (A) R0409

6-3337

Strap

,

Correa,

Sangle

Adjust spray pattern

by turning nozzle cap.

Do not turn cap more

than 2 turns or cap may

come off allowing spray

material to spray back

on you.

7. To Release Pressure

1. Hose to Tank

Make sure white outlet tube

is attached to hose.

Insert tube into tank.

Proper placement of

white outlet tube.

Line up tabs on safety lock

connector with notches on the

outlet flange of the tank. Insert

tabs into notches to form a

secure seal.

Slip hose nut down to

tank, turn clockwise

and tighten as tight as

possible by hand.

Note:

Your particular sprayer may not include all parts pictured above.

Nota:

Es posible que este pulverizador en particular no incluya todas las partes que se ilustran arriba.

Remarque :

Votre pulvérisateur particulier pourrait ne pas inclure toutes les pièces illustrées plus haut.

Do:

Turn handle clock-

wise to tighten. Push

handle down, turn 1/4

turn counterclockwise

to release.

Do:

Pump until you

feel resistance.

Do:

Push handle,

down, turn 1/4 turn

clockwise to lock. Begin

spraying. Re-pump

sprayer as required to

maintain spray force.

1A

1B

1C

1D

1E

Pull handle straight up.

Insert notches from

underside of handle

into plunger grooves

and turn counter-

clockwise.

Remove plunger and diaphragm.

Clean plunger, diaphragm

and body. Flip diaphragm and

replace.

Tighten plunger clockwise until

flush to top of shut-off body.

Do not over-tighten or unit

may not spray. Slide forks un-

der plunger, push handle down

until it snaps into place.

10. Troubleshooting

-

Tank pressurizes but does not spray.

10A

10B

10C

Handle

Plunger

Body

Diaphragm

10D

Plunger flush

with body

WARNING:

Release pressure in tank before troubleshooting.

Clean Nozzle Assembly (Fig. 10E) -Remove nozzle cap. Clean and re-assemble.

Clean shut-off (Fig. 10A- 10D)

For constant spraying, push down on shut-off handle and move grey locking

mechanism away from you. To release, squeeze handle and move the grey locking

mechanism back towards you. ( Not all models are provided with this feature).

9A

Locking

mechanism

10E

Nozzle Cap

Congratulations!

You have just purchased a quality Chapin product.

Register Your Sprayer Online @ www.chapinmfg.com

Questions?

Do Not Return To Store.

Call us @ 1-800-950-4458 or www.chapinmfg.com

¡Felicitaciones!

Usted acaba de adquirir un producto de calidad Chapin.

Registre su pulverizador en línea en www.chapinmfg.com

¿Preguntas?

No regrese a la tienda;

llámenos al 1-800-950-4458 o visite www.chapinmfg.com

Félicitations!

Vous avez acheté un produit de qualité Chapin.

Enregistrez dès que possible votre pulvérisateur en ligne à l'adresse suivante:

www.chapinmfg.com

Questions ?

Ne retournez pas au magasin.

Appelez-nous 1-800-950-4458 ou visitez le www.chapinmfg.com

3. Filter

The filter helps prevent clogging while spraying. It is located on the

end of the outlet tube inside your sprayer tank.To clean filter, remove

the discharge assembly from the tank (Fig.1A). Make sure the filter is

positioned at the bottom of the tank as pictured (Fig. 3A).

Note:

Filters are not supplied with deck sprayers.

Filter

3A

6B

6A

6C

6D

WARNING:

Handling the brass parts of this product will expose

you to lead, a chemical known to the State of California to cause

birth defects and other reproductive harm. Wash hands after

handling.

6-7770

Extension wand,

Vara de extensión, Rallonge

6-4631

Fan Nozzle

Tobera

Buse

Attach nozzle to shut-off handle or extension wand.

2A

1) Do: With pump facing away, turn locked handle counterclockwise until air begins to escape.

Stop turning handle when you hear air escaping.

2) Do: Stay away from the sprayer until all air has escaped.

9. Fatigue-Free Spraying

TO EXTEND EXTENSION - Grasp locking nut and turn counter-

clockwise until loose. Pull brass tube up to desired length and re-tighten

locking nut by turning clockwise until tight. DO NOT USE TOOLS AS

THIS WILL DAMAGE EXTENSION.

TO RETRACT EXTENSION - Grasp the locking nut and turn it counter-clockwise until loose. Push the brass tube

down into the base tube to desired length (CAUTION: POINT THE NOZZLE IN A SAFE DIRECTION. IF THE

EXTENSION HAS FLUID IN IT THE FLUID WILL SPRAY OUT OF THE NOZZLE WHEN PUSHING THE

BRASS TUBE DOWN, POSSIBLY CAUSING IT TO SPRAY ON YOU. YOU CAN ELIMINATE THIS BY RE-

MOVING THE EXTENSION FROM THE SHUT-OFF AND ALLOWING THE FLUID TO DRAIN.) Re-tighten

the locking nut by turning it clockwise to hold brass tube in position.

2B

2C