Chapin 7215015 User Manual

Warning, Parts, Filling

6-2000

Shut-off Handle

Hazard: Improper use or failure to follow instructions can result in explosive failure causing

serious eye or other injury.

For safe use of this product you must read and follow all instructions.

Do not leave a pressurized sprayer in the hot sun. Heat can cause pressure build-up. Do not store

or le

ave solution in tank after use. Always wear goggles, gloves, long sleeve shirt, long pants and full

foot protection when spraying. Never use any tool to remove pump if there is pressure in sprayer.

Never stand with face or body over

top of tank when pumping or loosening pump to prevent eject-

ing pump assembly and/or solution from striking and injuring you. Never pressurize sprayer by any

means other than the original pump. Do not attempt to modify or repair this product except with

original manufacturer’s parts. Never spray flammable materials or heat, pressure, or gas produc-

ing chemicals. Always read and follow manufacturer’s instructions before use with this sprayer

as some chemicals may be hazardous when used with this sprayer.

WARNING!

Sk-1113-1

Parts

6-2001

Hose Kit

Repair Parts Kit Gaskets and Seals

(not included) 6-1925

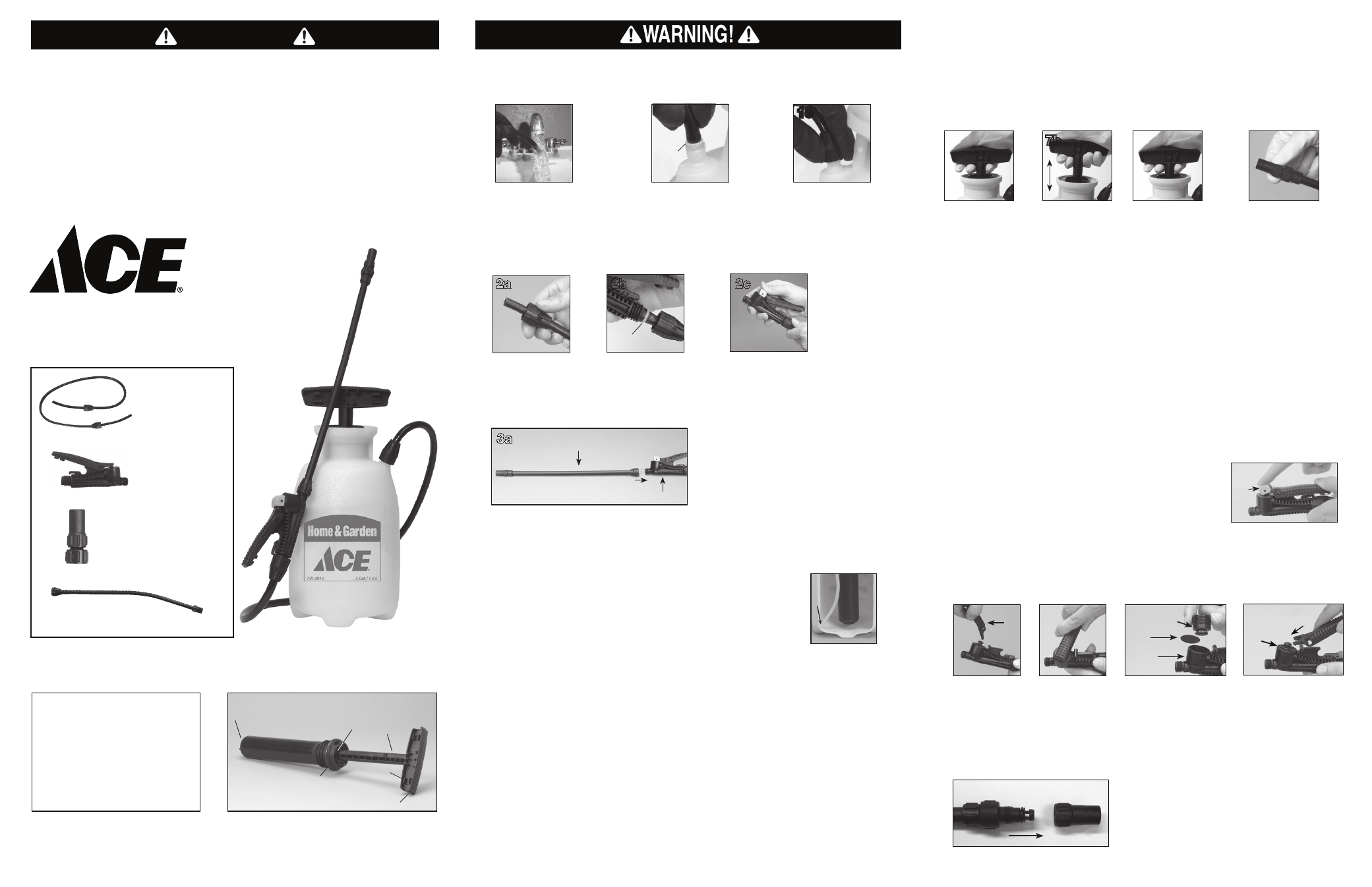

6. Filling

1) Do: Turn pump handle counterclockwise and remove pump

2) Do: Prepare spray solution following all directions and safety warnings on chemical label.

3) Do: Fill tank to no more than the proper gallon marker. Do NOT: overfill to accommodate pump.

4) Do: Check pump to make sure that no grass or dirt is stuck to barrel. Replace pump in tank and tighten securely.

7. Pressurizing and Spraying

9. Care, Storage and Maintenance

1) Do: Rinse tank thoroughly with water only, empty, refill with water. Follow Filling, Pressurizing and Spraying

Instructions, except pump unit only 8-10 strokes.

2) Do: Open shut-off and allow water to run through discharge assembly.

3) Do: Release pressure (Follow Pressure Release Instructions), remove pump and empty sprayer.

4) Do: Store sprayer tank upside down, with pump removed, in a warm dry location.

5) Do: Periodically oil pump by dropping 10-12 drops of light oil down pump rod through opening in cover.

6-6003

Nozzle

011198 (A) R0000

Pump until you

feel resistance.

Turn handle clockwise to

tighten.Push handle down,

turn 1/4 turn counter-

clockwise to release.

Push handle, down, turn 1/4

turn clockwise to lock. Begin

spraying. Re-pump sprayer

as required to maintain spray

force.

Adjust spray pattern by turn-

ing nozzle cap. Do not turn

cap more than 2 turns or cap

may come off allowing spray

material to spray back on you.

8. To Release Pressure

1) Do: With pump facing away, turn locked handle counterclockwise until air begins to escape.

Stop turning handle when you hear air escaping.

2) Do: Stay away from the sprayer until all air has escaped.

6-7748

Extension wand

Poly Half Gallon

Sprayer

20090

Repair kit (#6-1925)

and spare parts are

available at your local

ACE dealer or call

1-800-950-4458.

4. Filter

The filter helps prevent clogging while spraying. It is located on the end of the outlet tube

inside your sprayer tank.To clean filter, remove the discharge assembly from the tank. Make

sure the filter is positioned at the bottom of the tank as pictured (Fig. 4A).

Filter

4A

1. Hose to Tank

2. Shut-off to hose

To prevent hose from blowing off, hose must cover both barbs and touch flange (fig. 2) before

hose nut is tightened (fig. 3).

4

1c

1a

1b

flange

Do:

Place end of hose under hot tap

water for 1 minute. This will soften

the hose and help insure the hose is

pushed all the way down to the flange.

Do:

Push hose until it covers

both barbs and touches the

flange.

Do:

Slide nut down over

threads. Turn nut clock-

wise as tight as possible.

Pull handle straight

up.

Insert notches from

underside of handle

into plunger grooves

and turn counter-

clockwise.

Remove plunger and

diaphragm. Clean plunger,

diaphragm and body. Flip

diaphragm and replace.

Tighten plunger clockwise until

flush to top of shut-off body. Do

not over-tighten or unit may not

spray. Slide forks under plunger,

push handle down until it snaps

into place.

11. Troubleshooting

-

Tank pressurizes but does not spray.

11A

11B

11C

Handle

Plunger

Body

Diaphragm

11D

Plunger flush

with body

WARNING:

Release pressure in tank before troubleshooting.

Clean Nozzle Assembly (Fig. 11E)

Remove nozzle cap. Clean and re-assemble.

Clean shut-off (Fig. 11A- 11D)

10. Fatigue-Free Spraying

For constant spraying, push down on shut-off handle and move grey locking

mechanism away from you. To release, squeeze handle and move the grey

locking mechanism back towards you. ( Not all models are provided with

this feature).

10A

Locking

mechanism

11E

Nozzle Cap

2a

Slide nut on hose.

3. Nozzle

Push hose until it

touches the flange.

Turn nut clockwise as tight as pos-

sible so that the SAFETY CATCH

MAKES A CLICKING SOUND.

extension wand

shut-off handle

Attach extension wand to shut-off handle.

1) Do: Check tightness of hose nut to be sure hose is securely attached to the tank outlet.

2) Do: Inspect hose for deterioration, cracks, softness, or brittleness. If any of these conditions are found, replace hose

before using. Replace with original manufacturer’s parts only.

3) Do: Remove pump (see Filling, Pressurizing and Spraying Instructions), inspect interior and exterior of tank for signs

of deterioration of body and bottom. Any sign of deterioration indicates possible tank weakening and could result in

explosive bursting under pressure. If any of these signs are found, discard tank immediately and replace. Do not

attempt to patch leaks, etc., as this could result in serious injury.

4) Do: Follow Filling, Pressurizing and Spraying Instructions, except use water only.

5) Do: Pump plunger 10-15 strokes and inspect for leaks.

6) Do: Direct shut-off away from you and open to make sure discharge is not clogged.

7) Do: If unit passes this test, release pressure (see Pressure Releasing Instructions), empty tank, and proceed with Filling,

Pressurizing and Spraying Instructions.

5. Pre-Use Check

Pump Assembly

Check valve

Pump Barrel

O-ring seal

Extension

holder

Lubricating

oil here

Plunger rod

Handle

2b

2c

flange

7d

7b

7c

7a

3a