2 error messages and notifications, Troubleshooting – Hach-Lange SIGMA SD900 Refrigerated Sampler and All Weather Refrigerated Sampler User Manual User Manual

Page 90

88

Troubleshooting

7.2 Error messages and notifications

Messages will be shown in the controller display when errors occur

or to confirm that an operation is complete. Refer to

for a

description of the possible messages.

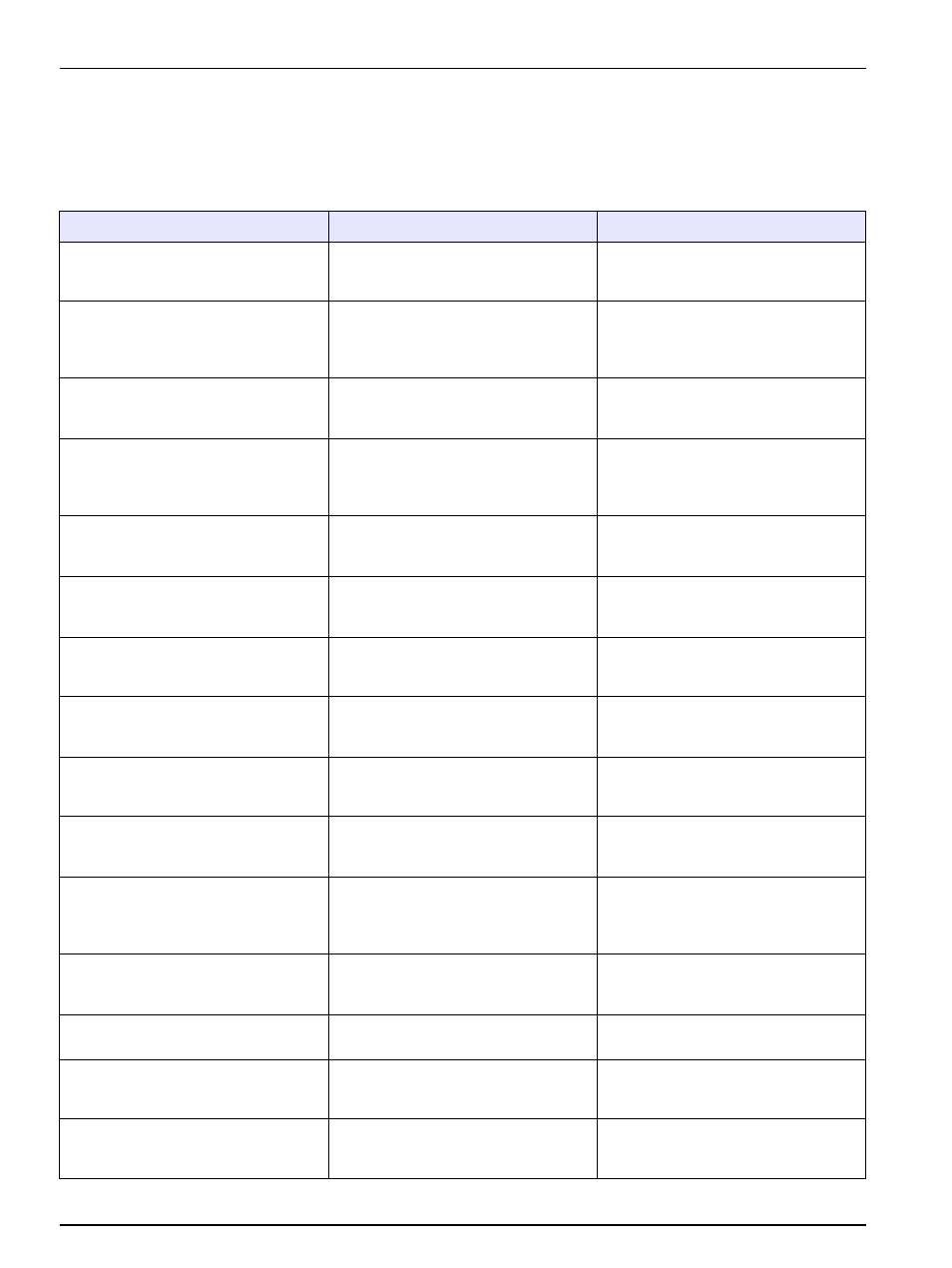

Table 8 SD 900 error and information messages

Message

Reason

Action

ERROR

WRONG RANGE

The value that was entered is outside of

the acceptable range.

Press

BACK

or

ENTER

. Enter a valid

number that is within the range specified

on the bottom of the screen.

BOTTLE NUMBER

OUTPUT DISABLED

ON PIN F

Message is displayed when program

complete output is enabled. The bottle

number output on the auxiliary port

(pin F) is automatically disabled.

Press BACK or ENTER to keep

program complete output enabled. If

bottle number output is preferred,

disable the program complete output.

NOT ALLOWED

CANNOT ENABLE SETPOINT SAMPLING

AND STORM WATER

An attempt was made to enable setpoint

sampling and stormwater sampling at

the same time.

Disable setpoint sampling or stormwater

sampling, then enable the preferred

option.

NOT PERMITTED.

END THE PROGRAM FIRST TO ACCESS

THIS FEATURE

An attempt was made to access a menu

such as program setup, system setup,

volume calibration or manual operation

while a program was running.

Press

BACK

or

ENTER

and select

END PROGRAM

or

CANCEL

to continue

the program.

NEED TO CAL.

LIQUID SENSOR IS DISABLED.

CAL IS REQUIRED!

The liquid sensor was disabled and a

manual volume calibration is required.

Calibrate all volumes as specified in

NEED TO CAL.

LIQUID SENSOR IS ENABLED. SENSOR

REQUIRES CAL

The liquid sensor must be calibrated.

Calibrate the liquid sensor as specified

in

.

DISTRIBUTOR

MOVE IS COMPLETE

Confirmation that the distributor arm

was moved to a specific bottle position

and the move is complete.

Press

BACK

or

ENTER

to acknowledge

the information.

NOT ALLOWED.

1 BTL CONFIGURED DISTRIBUTOR NOT

RELEVANT.

An attempt was made to move the

distributor when the program setup was

set to a single bottle.

Change the bottle number configuration

in the program setup menu before

moving the distributor.

RESET CAL.

VALUE HAS BEEN RESET TO 0.

Confirmation that volume calibration

with the liquid sensor enabled was reset

to 0 in the volume calibration menu.

Press

BACK

or

ENTER

to acknowledge

the information. The liquid sensor is no

longer calibrated.

NOT ALLOWED.

ENABLE LIQUID SENSOR TO

PERFORM CAL

An attempt was made to calibrate the

liquid sensor when the liquid sensor was

disabled.

Enable the liquid sensor in the program

setup menu.

BOTTLE NUMBER OUTPUT ENABLED ON

PIN F

Confirmation that the bottle number

output on pin F of auxiliary port is

enabled when the program complete

output is disabled.

Press

BACK

or

ENTER

to acknowledge

the information.

CANNOT ENABLE.

PGM START/STOP AND STORM WATER

AT SAME TIME

An attempt was made to enable

start/stop time and stormwater at the

same time.

Disable start/stop time or stormwater in

the advanced sampling menu, then

enable the preferred option.

FAULT.

PUMP FAULT

The pump failed to operate properly.

Examine the pump for obstructions.

ALARM.

CHANGE TUBE

The specified maximum number of

pump cycles have expired. The pump

tube should be changed.

Change the pump tube and reset the

maximum number of pump cycles

(

FAULT.

ARM FAULTY

The distributor arm failed to operate

properly.

Make sure the distributor arm is

connected properly and can move freely

in both directions.