Caution – Cashco 988-MB User Manual

Page 8

8

IOM-988/989-BODY

6. Remove all bonnet stud nuts (17).

7. Lift bonnet (2), plug/stem assembly (3), cage (10),

and all pack ing zone parts up and out of the body

(1) - grasp stem to prevent from falling. Lay these

parts down horizontally on a workbench. NOTE:

Seat ring (11) (and seat retainer (23) and soft seat

insert (24) for composition/soft seated de signs)

may also pull out with above parts assembly.

8. Remove both stem nuts (52).

9. Withdraw plug/stem assembly (3) from within the

bon net (2) and packing (6). Hold cage (10) to

pre vent from dropping. Set parts (3,10) aside.

10. Place the bonnet (2) into a second vise with the

pack ing zone on top. Remove packing nuts (15).

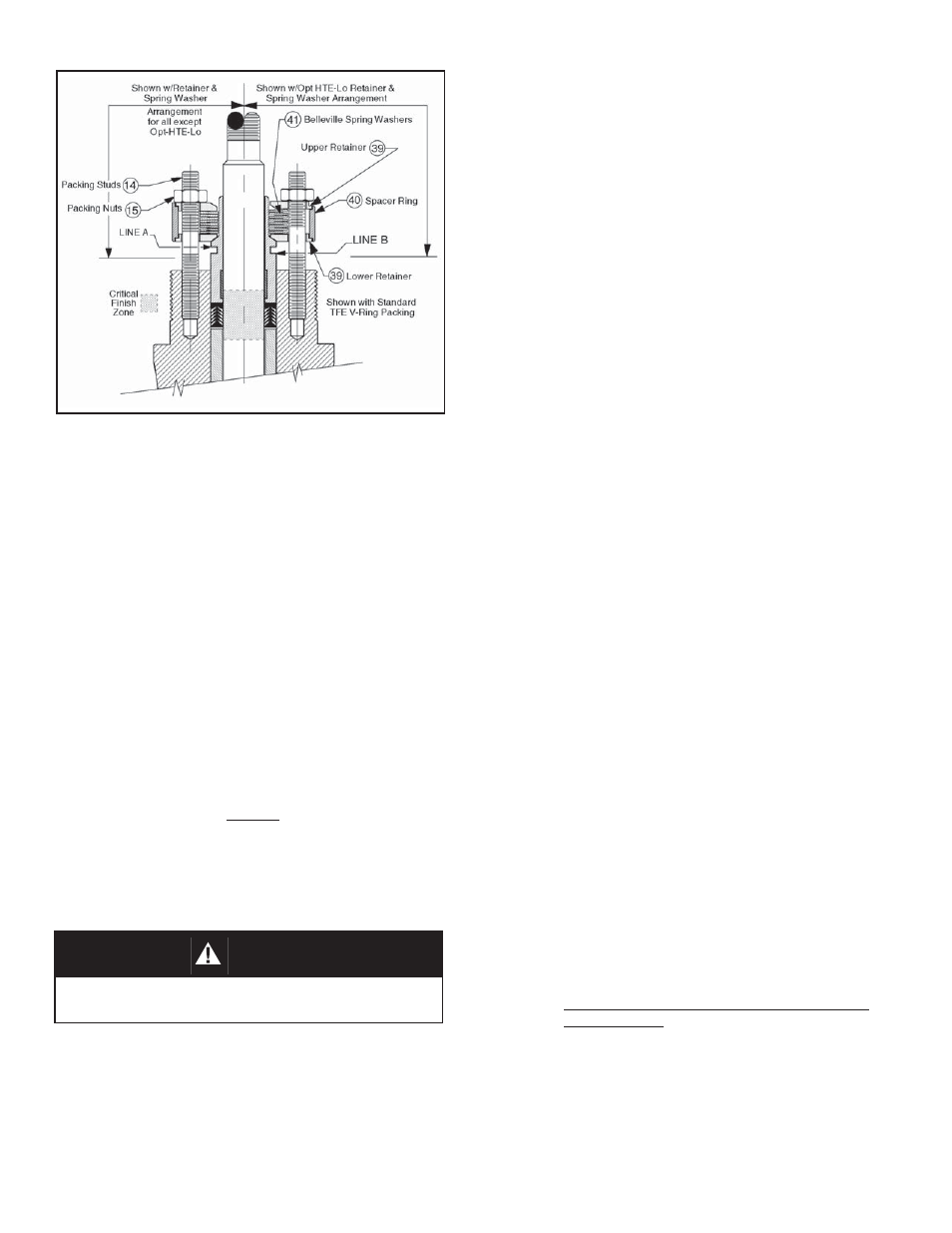

11. Grasp the lower retainers (39) from its underneath

side and lift the lower retainers, spacer rings (40),

Belleville spring wash er stacks (41), and upper

re tain ers(39) together up and over the packing

studs (14). Set these parts (39,40,41) aside without

disturbing the orientation.

12. Remove packing follower (5) together with fol low er

bush ing (26 or 5.2). Discard Rulon tape bushing

(26) if supplied.

15. Solvent clean all parts to be reused including bon-

net (2). Examine all parts for wear and corrosion.

Re place any cor rod ed or worn parts. Belleville

spring wash ers (41), studs (14,16), nuts (15,17)

and retainers (39) should be replaced in sets.

16. Examine plug/stem (3) at lower guide bushing area

(8) for wear. If there are signs of excess wear, guide

bushing should be replaced:

a. Place the bonnet (2) on a bench press. Press

the guide bush ing (8) out of the bonnet and

dis card.

b. Rotate bonnet (2) end-for-end. Place a new

guide bush ing (8) into position and press fully

into the bonnet.

c. Reclean bonnet with suitable solvent.

17. Examine plug/stem (3) in critical fi nish zone where

con tact is made with the packing (6). It is desirable

to re store the surface of the stem to a #4 Ra μ-in

surface fi nish; metal removal should not exceed

0.001 inch material. A deeply scratched or pitted

stem should be replaced.

18. Examine plug/stem (3) for wear around the seating

area. Ex am ine seat ring (11).

a. Plug head of stem assembly (3) of metal

seat ed design may be hand lapped using

suit able lap ping compound. If hand lapping will

not re store sur fac es to an acceptable de gree,

then re place ment of plug/stem assembly is

rec om mend ed.

b. For composition seated design, if plug/stem

as sem bly (3) is wear damaged, the stem (3)

should be re placed.

19. Examine inner surface of the bonnet’s (2) stuffi ng

box. It is desirable to restore the surface of stuffi ng

box to a #8 Ra μ-in surface fi nish; metal re mov al

should not exceed 0.001 inch ma te ri al. A deeply

scratched or pitted bonnet (2) should be re placed.

20. Examine packing follower (5) for corrosion. Re-

place if sig nifi cant ly corroded:

a. Place new follower bushing tape (26) into fol-

low er’s (5) interior groove.

b. If packing Opt-HTE-Hi or Opt-HTE-Lo is sup-

plied, the pack ing follower (5) contains carbon

bushing (5.2) that is pressed into the fol low er

(5.1). This bushing (5.2) is not fi eld re place-

able and must be supplied as a packing fol-

low er sub-assembly (5). Ex am ine the car bon

bush ing (5.2) for wear or cor ro sion. Re place

follower sub-as sem bly when nec es sary.

21. Turn attention to the body (1) and the remaining

parts yet therein. Remove seat ring (11) (and seat

retainer (23) and soft seat insert (24) for com po si-

tion/soft seated design). Discard used soft seat

in sert (24); always use a new soft seat insert upon

reassembly, If seat ring(11) or seat retainer (23)

are dam aged, replace.

Figure 4: External Live Loaded Packing Orientation

CAUTION

Take extreme care to not mar internal wall surface of the

bonnet (2).

13. Using a sharp, hooked-end, pick-type tool, hook

and pull the packing rings (6) up and out of the

bonnet’s (2) stuffi ng box individually. Examine for

excessive wear. Discard pack ing.

14. Remove bonnet (2) from the vise and invert to al-

low packing spacer (9) to slide out of the bonnet’s

stuffi ng box.