Iv. startup, Caution – Cashco 988-MB User Manual

Page 3

3

IOM-988/989-BODY

C. Removal From Piping System:

1. Care should be taken in removal of separable

fl anged units. Run wire in 180° crossing pattern

through bolt holes to prevent fl anges from coming

loose during handling.

IV. STARTUP

A. General:

1. Ensure that the Model 988/989 unit has been

prop er ly ad just ed and calibrated, including the

positioner if in stalled.

2. Recommend startup to be in a “manual” mode.

This pro ce dure assumes double block (iso la tion)

and bypass valves for the “control valve sta tion”.

See Figure 1.

3. Start with either of the two block valves closed,

with the oth er open. The bypass valve should be

closed. Pressurize sys tem if possible/practical.

4. Back out the airset’s adjusting screw until loose.

5. Turn on air supply pressure.

6. Adjust the air supply airset (fi lter-regulator) to the

prop er lev el as indicated as follows:

Bench Setting

Airset Output

psig (Barg)

psig (Barg)

5–15 (.34–1.0)

20 (1.4)

15–60 (1.0–4.1)

75 (5.2)

7. Place loop controller into “manual” mode. Vary

set ting from minimum – mid-range – max i mum

SIG out put. Observe re sponse of con trol valve unit

to these chang es of in put SIG. The valve should

fully stroke at the vari a tion from min i mum SIG to

max i mum SIG; the mid-range SIG should have the

valve stem travel at/near 1/2 open.

8. Confi rm that action of controller and positioner

– direct or reverse – are pro duc ing the desired re-

sponse in the con trol unit. Confi rm that the control

valve “fail” po si tion is as required.

9. Hereafter, the procedure assumes that actual fl u id

fl ow may be established. This may not be prac ti-

cal/pos si ble in all cas es; if so, vary procedure as

re quired. Always “heat” or “cool” down the system

piping SLOW LY by open ing the control valve sta-

tion by pass valve in small increments.

10. With one of the control valve station block valves

still closed, and the loop controller still in “manual”

mode, open by pass valve and vary fl ow rate man u-

al ly to observe the response of the con trol ler and

control valve unit to geth er.

11. Attempt to develop manual control of the loop by

open ing/closing the manual bypass as re quired,

or by manually con trol ling mainstream fl ow as

re quired.

12. When the control valve is partially open, slowly

crack open the closed block valve while si mul ta-

neous ly closing the bypass valve. Continue this

pro ce dure until the bypass is closed and the block

valves are both fully open. The system is still un-

der “man u al” mode control, but all fl ow is pass ing

through the control valve.

13. Vary controller “manual” SIG output until match ing

the “au to mat ic” SIG output, then change the mode

of the controller over to “automatic”. The loop will

ex pe ri ence a minimum of upset conditions, and will

be in au to matic control.

CAUTION

DO NOT WALK AWAY AND LEAVE A MANUALLY CON-

TROLLED CONTROL VALVE UNATTENDED!

SECTION IV

CAUTION

Exhibit care in handling fl anged units to prevent sep a ra ble

fl ang es from coming loose, falling to fl oor and smashing

feet/toes.

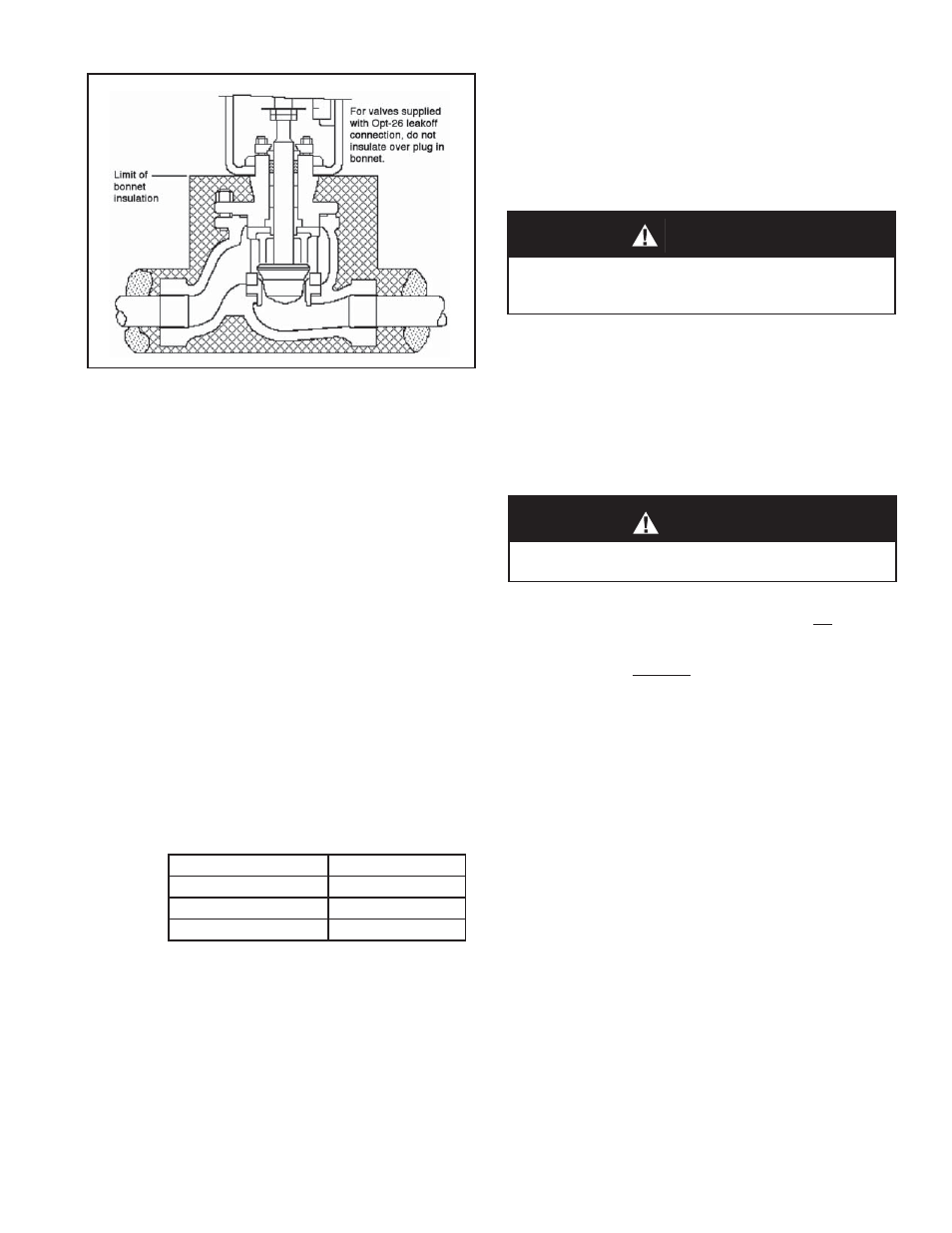

Figure 2: Body Insulation