Cashco 988-MB User Manual

Page 13

13

IOM-988/989-BODY

VI. CALIBRATION

A. General:

1. This section only covers cal i bra tion of the

control valve with Actuator Models C27/C53.

2. Positioner,

if

in

stalled, requires ref er ence to

the spe cifi c positioner mod el IOM for prop er

cal i bra tion pro ce dure.

3. All indicated items numbers that are with

re spect to IOM-C27-C53 will be in pa ren-

the sis and un der scored; i.e. (20); those that

reference the po si tion er IOM will be in double

paranthesis; i.e. ((AP)). All item numbers that

are with respect to this IOM-988/989 are not

un der scored; i.e. (3).

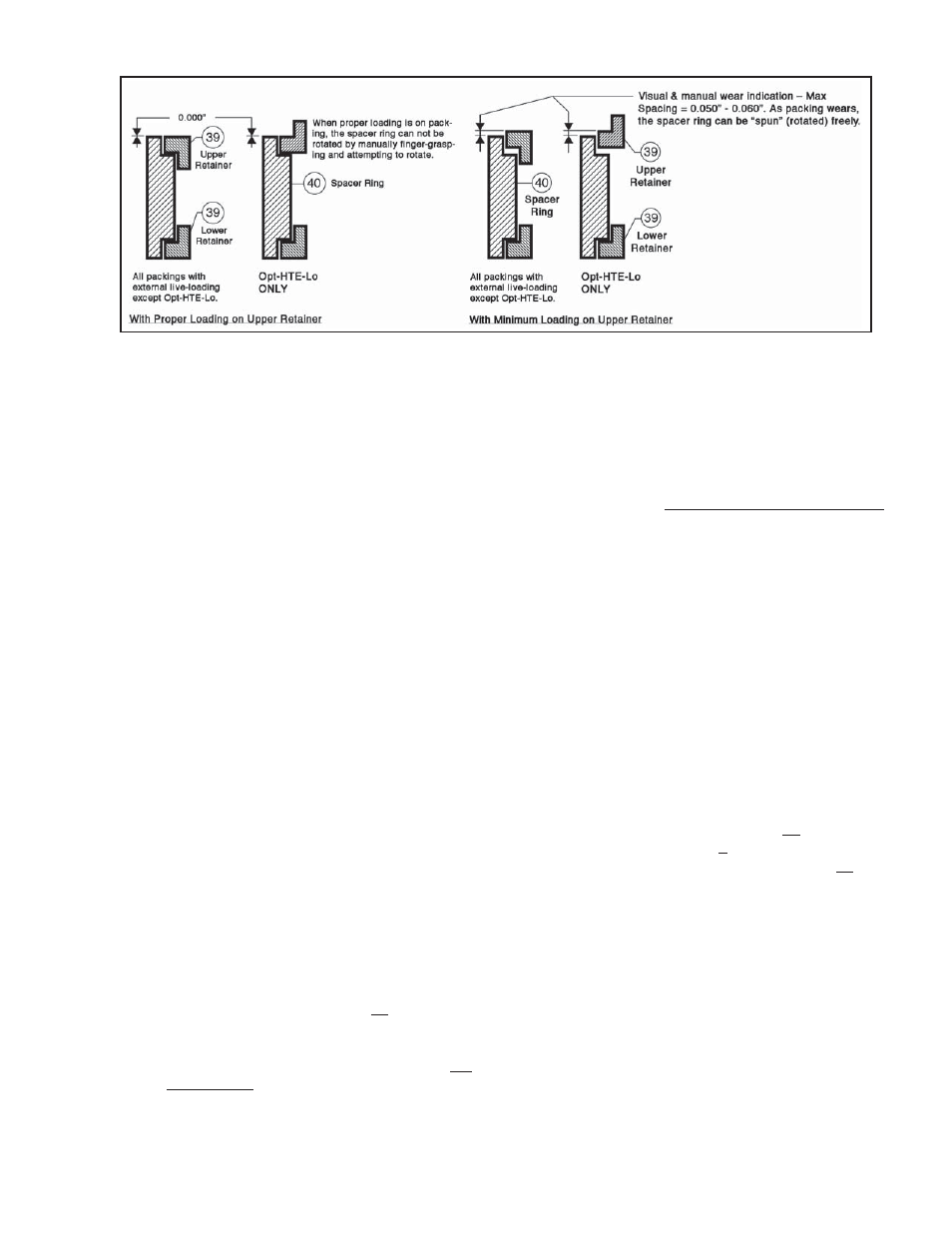

Figure 11: Dimensionals for Proper Packing Load

G. External Live-Loaded Packing Adjustment:

1. There are two types of indicators for determining

“pack ing wear” –

a. Ability to “freely spin” the spacer rings (40).

b. Measure the spacing between the upper re-

tain ers (39) spacer rings (40) (see Fig. 11).

NOTE: Regardless of live loaded packing design, all

use the same method for obtaining the proper pre-load

to new or used packing.

2. To properly tighten packing, grasp spacer ring

(40) be tween the thumb and forefi nger at points

approximately 180° from each oth er.

a. Tighten packing stud nuts (15) in 1/2 revolu-

tion in cre ments, al ter nat ing from one nut to

the other, while attempting to rotate the space

rings (40).

b. Once spacer rings (40) can no longer be

ro tat ed by the fi n gers, attempt to “even”

the op po site packing nut (15) so that the

upper re tain ers (39) are level, then add 1/2

rev o lu tion to each pack ing nut. Adjustment

completed.

3. If the spacing between the upper retainers (39)

and spac er rings (40) are used as visual indicator,

the spac ing should not ex ceed 0.060" (1.5 mm)

(ap prox i mate ly 1/16"). When this level of “packing

wear” is in di cat ed, adjustment per Step 2. above

is re quired.

4. Packing (6) adjustment can be made at any time.

NOTE: If packing (6) live-load is set too high, the

pack ing will act as non-live-loaded, jammed packing.

Ex cess actuator thrust will be required and packing

wear will be accelerated.

SECTION VI

B. Procedure - Reverse Action, ATO-FC:

1. Reference the name plate (40) at tached to

the ac tu a tor yoke (3). De ter mine the bench

set ting of the in stalled range springs (10) from

the name plate; i.e. 5-15 psig (.34 -1.0 Barg),

or 15-60 psig (1-4.1 Barg).

2. Connect a temporary air supply with an in-line

ad just able airset regulator and gauge to the

lower actuator con nec tion. See Section IV. A.

6. for appropriate supply pressure. DO NOT

LOAD with any air pressure at this point.

3. To determine when stem/plug (3) begins to

lift out of the seat, touch the stem above the

packing studs with one fi nger. (Stem will be-

gin to move when actuator pressure exceeds

the spring load.)