Cashco 988-MB User Manual

Page 11

11

IOM-988/989-BODY

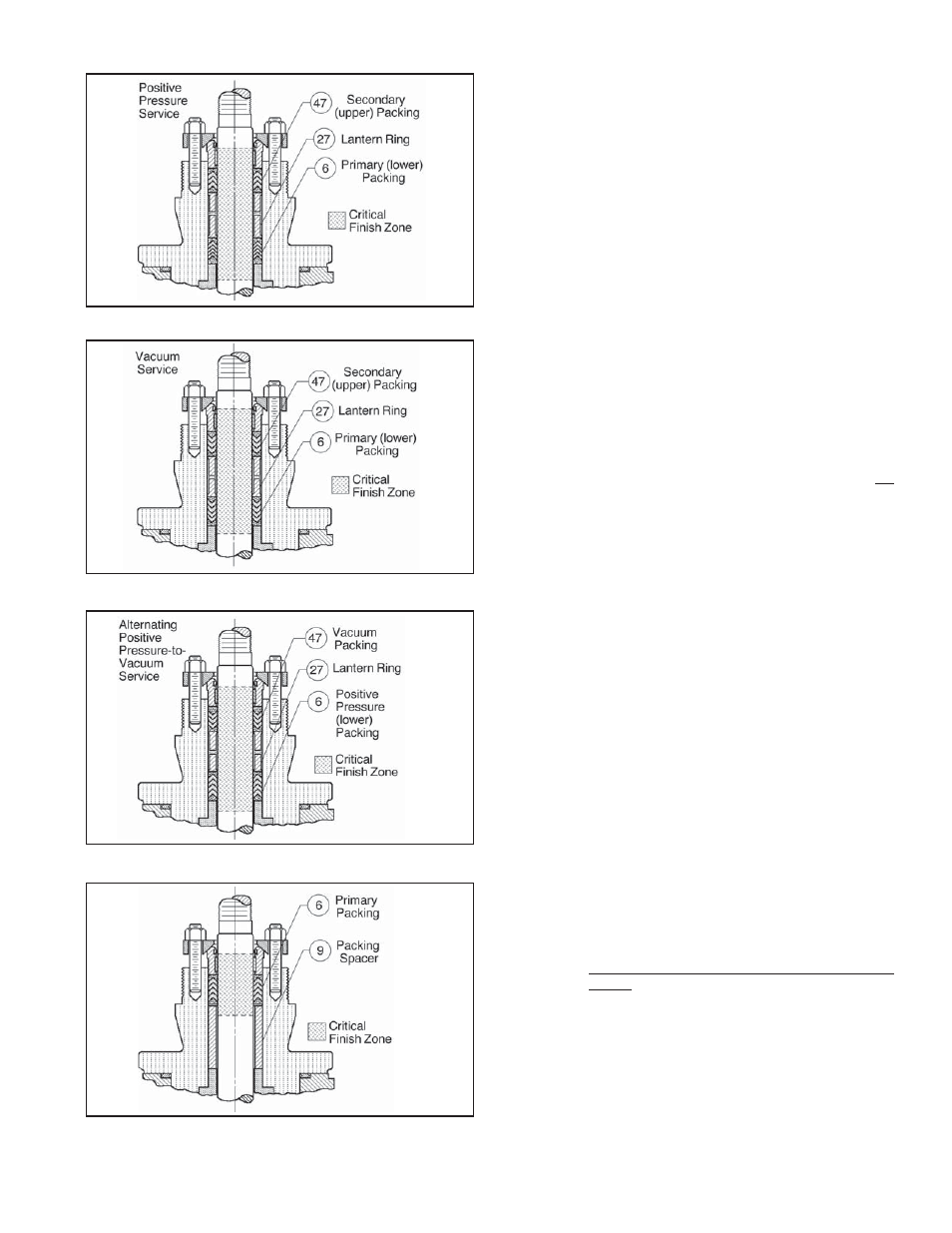

b. Using a sharp, hooked-end, pick-type tool,

hook and pull the primary lower packing ring

set (6) up and out of the bon net’s (2) stuffi ng

box individually. Examine for proper ori en ta-

tion (see Fig ures 7, 8 and 9).

11. Solvent clean all parts to be reused, including

bon net. Examine any parts for wear and cor ro sion.

Re place any corroded or worn parts. Discard old

pack ing.

12 Examine plug/stem (3) at lower guide bushing (8)

area for wear. If there are signs of excess wear,

guide bushing should be replaced:

a. Place the bonnet (2) on a bench press. Press

guide bush ing out of bonnet and dis card.

b. Rotate bonnet end-for-end. Place a new guide

bush ing into position and press fully into the

bonnet.

c. Reclean bonnet with suitable solvent.

13. Examine plug/stem (3) in critical fi nish zone where

con tact is made with the packing (6,47). It is de-

sirable to re store the surface of the stem to a #4

Ra μ-in surface fi nish; metal removal should not

exceed 0.001 inch material. A deeply scratched

or pitted stem should be replaced.

14. Examine plug/stem (3) for wear around the seating

area. Ex am ine seat ring (11).

a. Plug head of stem assembly of metal seat ed

design may be hand lapped using suit able

lap ping com pound. If hand lap ping will not

re store sur fac es to an ac cept able degree,

then re place ment of plug/stem assembly is

rec om mend ed.

b. For composition seated design, if stem as sem-

bly is wear damaged, the plug/stem should be

replaced.

15. Examine the inner surface of the bonnet’s (2)

stuffi ng box. It is desirable to restore the surface

of stuffi ng box to a #8 Ra μ-in surface fi nish; metal

re mov al should not exceed 0.001 inch ma te ri al. A

deeply scratched or pitted bonnet (2) should be

re placed.

16. Examine packing follower (5) for corrosion. Re place

if sig nifi cant ly corroded:

a. Replace follower bushing (26) with new bush-

ing (26).

b. Replace wiper ring (22) with new ring (22).

17. Turn attention to the body and remaining parts yet

there in. Remove seat ring (11) (and seat re tain er

(23) and soft seat in sert (24) for com po si tion/soft

seated de sign). Discard used soft seat in sert (24);

always use a new soft seat insert upon re as sem bly.

If seat ring or seat retainer are damaged, replace.

18. Examine gaskets (12, 13) to see if leakage oc-

curred. Re move and discard both the seat ring

gas ket (13) and bonnet gas ket (12). Always use

new gaskets (12, 13) upon reassembly.

Figure 7: Dual Packing – Arr. “A”, Opt-34A

Figure 8: Dual Packing – Arr. “B”, Opt-34B

Figure 9: Dual Packing – Arr. “C”, Opt-34C

Figure 10: Jammed Packing, Opt-38J