Cashco C-BPV User Manual

Page 6

IOM-C-BPV

6

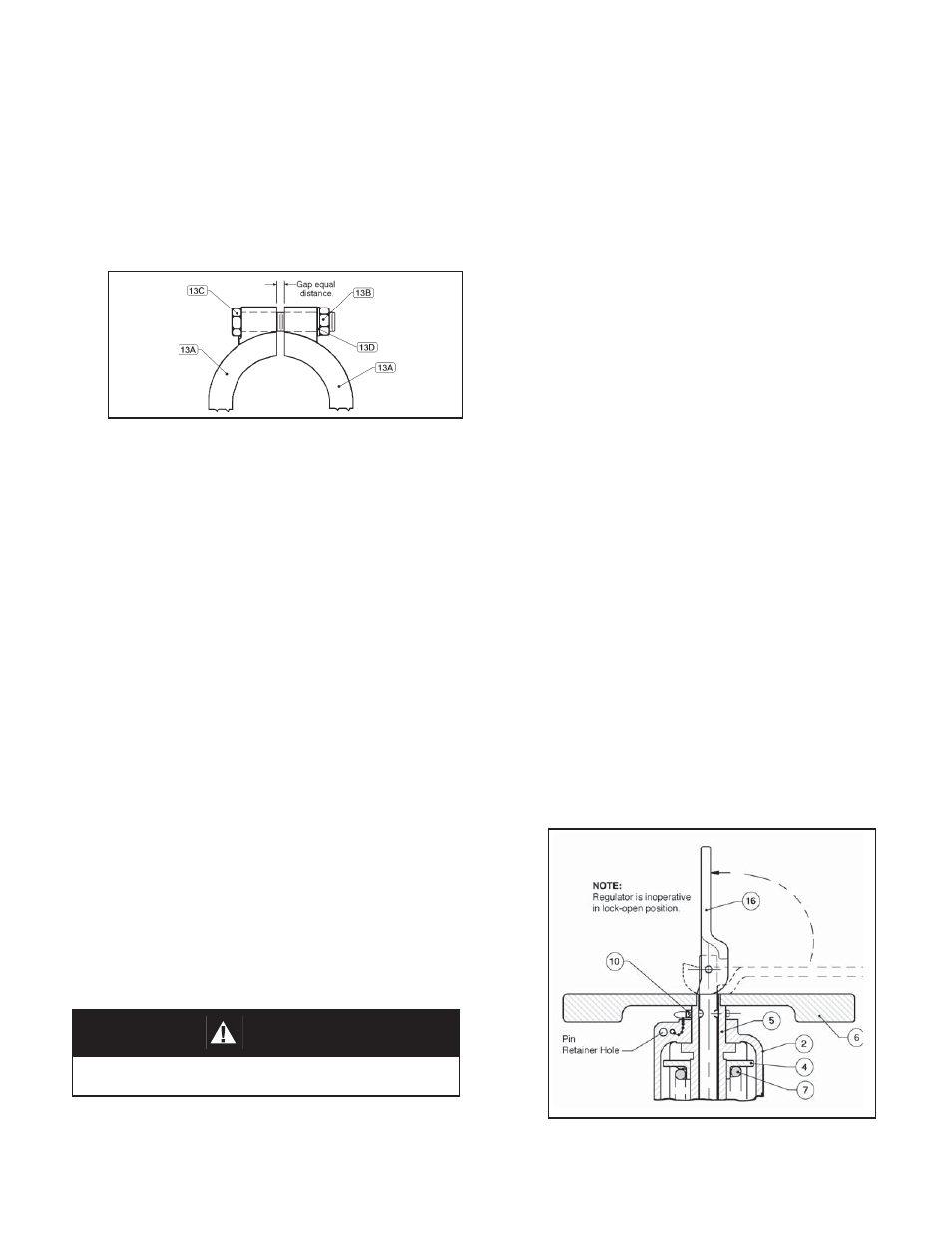

Figure 2: Spring Chamber in Lock-Open Position.

CAUTION

Owner’s cleaning solution must be compatible with regu-

lator’s trim materials.

n. Position the clamp (13) halves around

the mating fl anges of the body (1) and

the spring chamber (2). Insert clamp

bolts (13C), wash ers (13D) and tighten

clamp nuts (13B) in alternating pattern.

The clamp should be tightened to ap-

proximately 4 to 6 ft-lbs. (NOTE: Gap

be tween clamp (13A) halves should be

equal in size.

VII.CLEANING PROCEDURE

A. Pre-Sanitation:

1. Owner should refer to owner’s operating

pro ce dures for system shutdown to include

re liev ing all system pressure.

2. Refer to Fig. 3 and 4 for item number reference ().

3. Lift lever (16) to vertical position. NOTE: Do

not change range spring (7) setting by ro tat ing

adjustment nut (6) or handle (36).

4. Remove the lock-open pin (10) from the pin

retainer hole in the spring chamber (2) and

insert it into drilled passage through the ad-

just ing screw (5). (See Fig ure 2.)

B. Sanitation:

1. Flush, drain and sanitize system in ac cor-

dance to owner’s spec i fi ca tions.

NOTE: CIP is limited to 50 psig (3.45 Barg) maximum cleaning

solution pressure at 300°F (149°C). SIP is rec om mend ed to 20

psig (1.38 Barg) sat u rat ed steam pres sure; can withstand 30

psig (2.07 Barg), but may reduce elas tomer life ex pect an cy.

C. Post-Sanitation:

1. Prior to system start-up, remove the lock-open

pin (10) from the adjusting screw (5) and insert

it into the pin retainer hole. Lower lever (16)

to horizontal position. Unit is again op er a tive

at the setpoint es tab lished prior to cleaning.

SECTION VII

o. Replace eye nut (27) on guide post (22).

Ref to Section VI B. 3b previous to recall

the number of revolutions recorded for

removal.

p. Insert spring pin (32) through eye nut (27)

and guide post (22).

q. Place collar (28), bearing plate (29) and

base slide assembly (24) over guide post

(22).

r. Position cam (16) over guide post (22)

and insert quick release pin (15) through

holes in cam and post.

s. See Section IV for start up and adjustment

of set point and Section VII for Cleaning.

Figure 1: Clamp Arrangement.