Cashco 2171 User Manual

Page 4

4

IOM-1171/2171

10. Reassemble diaphragm subassembly by

plac ing pis ton O-ring (13), diaphragm(s)

(10), pres sure plate (3) and lock washer (6)

over thread ed post of piston(12). Assure the

pres sure plate (3) is placed with curved outer

rim down next to the diaphragm (10) surface.

Place a thread sealant com pound similar to

Loctite #271 on the threads of the piston's

post (12) prior to tightening the pressure plate

nut (7) to the fol low ing torque values:

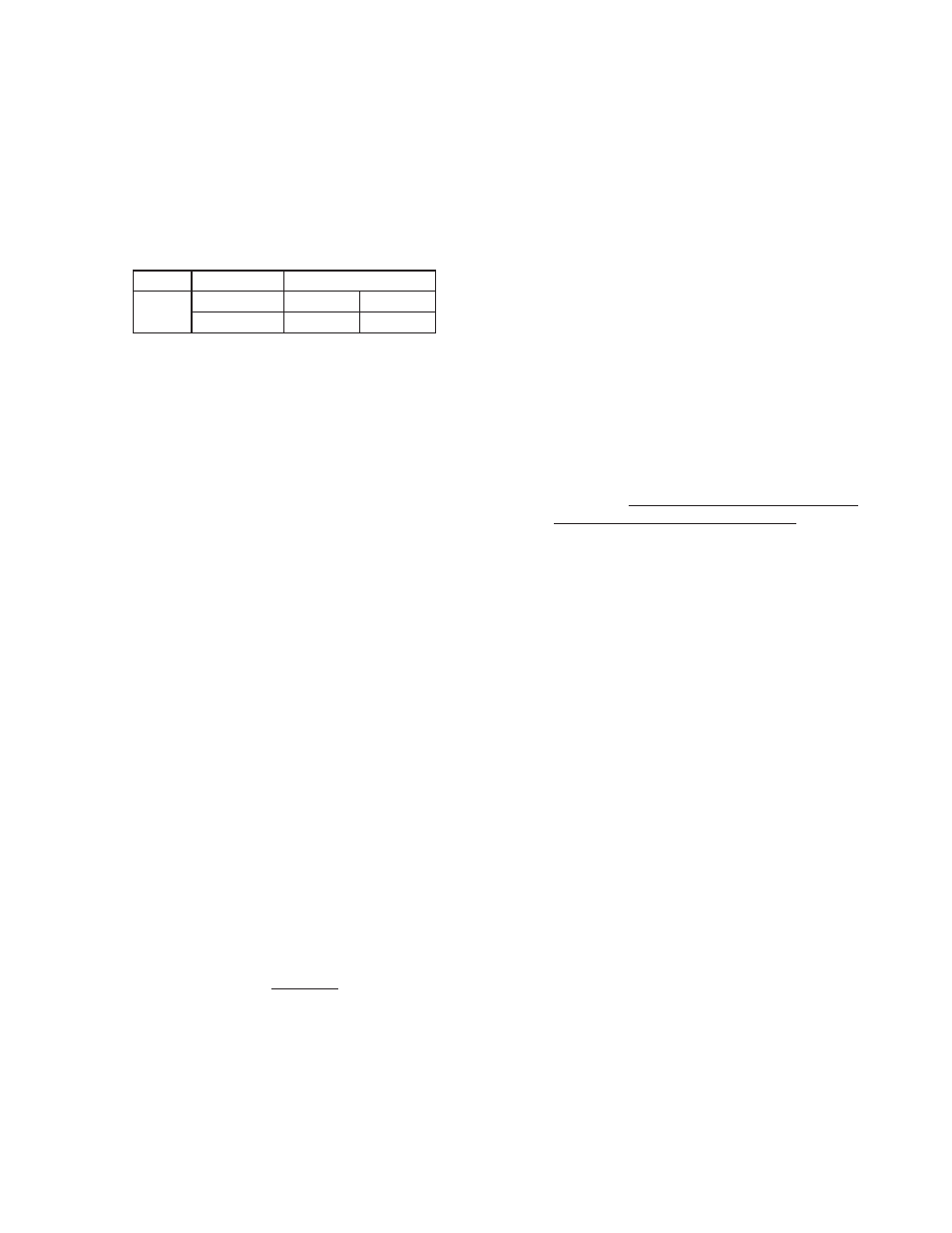

Sizes

Diaphragm

Torque

ALL

Metal

60 In-lbs

(6.8 N-m)

Composition

15 In-lbs

(1.7 N-m)

11. For metal diaphragm(s) (10), place dia-

phragm gas ket (11) into body (1) re cess

(none re quired for com po si tion di a phragm).

Set di a phragm sub as sem bly into the body.

12. Place the range spring (16) over the pressure

plate nut (7) of the diaphragm subassembly.

13. Place multipurpose, high temperature

grease into de pres sion of spring button (4)

where ad just ing screw bears. Set spring but-

ton (4) onto range spring (16); assure spring

button is laying fl at on spring.

14. Rotate the spring chamber (2) CW by hand

into the threaded portion of the body (1) as-

sur ing not to cross thread. NOTES: Inspect

and clean threads prior to reassembly. For

the Model 2171 apply an appropriate thread

lubricant to the spring chamber (2) threads

prior to re as sem bly to prevent seizing to-

gether with body (1). Con tin ue hand rotating

CW until fi rm ly seated against the upper

di a phragm gasket (11). Tighten the spring

chamber (2) and body (1) connection to the

following torque value: All sizes - 30-35 Ft.

lbs (41-47 Nm).

15. Reinstall ad just ing screw (5) with locknut (8)

into the spring chamber (2).

16. Pressurize body with air and spray liquid leak

de tec tor around body (1) and spring cham ber

(2) to test for leakage. Ensure that an inlet

pres sure is maintained during this leak test

of at least mid-range spring level; i.e. 20-80

psig (1.4-5.5 Barg) range spring, 50 psig (3.4

Barg) test pres sure min i mum.

C. Diaphragm Re place ment - Model 2171:

1. Procedures are the same as Model 1171.

2. For SST body (1) and SST spring chamber

(2), use thread lubricant to minimize po ten tial

of seizing threads.

D. Special Instructions for Diaphragm Re mov al:

1. If the TFE coated diaphragm is utilized on the

Model 2171, the TFE coating is the wetted

side of the diaphragm.

2. If the Option -2 handwheel is utilized, the ad-

just ing screw (5) and locknut (8) are re placed

with a handwheel (17) and lock nut (8). With

the Option-22 panel mounting w/handwheel,

the ad just ing screw and lock nut are replaced

with a handwheel (17), lock nut (8) and a panel

mounting nut (18).

3. Use only those gaskets manufactured and

sup plied by Cashco, Inc.

E. Piston Replacement:

1. Trim removal requires that diaphragm sub-

as sem bly be removed. Refer to previous

pro ce dure, Sec tion VI.B.

2. Inspect inside surface of cylinder. (NOTE:

The cylinder is an integral part of the body of

the 1171. Replace the regulator should any

damage be noted on the cylinder). If seat

shows no erosion/wear on seating surfaces,

piston (12) alone may be replaced.

3. Clean body (1) cavity. Clean all parts to be

reused. NOTE: On regulators originally sup-

plied as “oxygen clean”, Option's 1171-5-55,

2171-36-55, main te nance must include a

lev el of cleanliness equal to Cashco's clean-

ing stan dard #S-1134. Contact factory for

de tails.

4. Use special care cleaning the body (1) and

cyl in der shoulder, as this pressurized joint is

metal-to-metal with no gasket.

5. Reinstall diaphragm subassembly per Sec-

tion VI.B., Diaphragm Replacement.

6. Bench test unit for suitable operation. NOTE:

Reg u la tors are not tight shut off devices.

Even if pressure falls below setpoint, a reg u-

la tor may or may not develop bubble tight

shut off. In general, tighter shut off can be

ex pect ed with composition seat.

7. Spray liquid leak de tec tor to test for leakage

around body (1) and spring cham ber (2). Test

pressure should be the max i mum allowed by

the range spring (16) at the inlet.