Cashco 31-N User Manual

Page 2

IOM-31-N

2

7. In placing thread sealant on pipe ends prior to

en gage ment, assure that excess material is

re moved and not allowed to enter the regulator

upon startup.

6. Clean the piping of all foreign material including

chips, welding scale, oil, grease and dirt before

in stall ing the regulator. Strainers are rec om -

mend ed.

8. Flow Direction: Install so the fl ow direction match es

the arrow cast on the regulator body.

9. Refer to Figure 2. Regulator may be rotated

around the pipe axis 360°, and may be installed

in a horizontal or vertical pipeline. Four orientation/

arrangement assembly positions are standard. Ori-

ent to prevent the spring chamber vent hole from

collecting rainwater or debris. Reorient ac tu a tor

around the stem axis 360° if nec es sary.

10. Regulators are not to be direct buried un der -

ground.

11. For insulated piping systems, recommendation is

to not insulate regulator.

12. Cashco does not recommend fi eld welding on

the body of the regulator. If weld connections are

desired, specify Opt-32, extended plain end pipe

nipples.

SECTION III

up wards movement of the diaphragm due to the

P

2

pressure. As outlet pressure drops, the range

spring pushes the diaphragm down, opening the

regulator’s port via the linkage lever travel. As

outlet pressure increases, the diaphragm pushes

up against the range spring and the port closes.

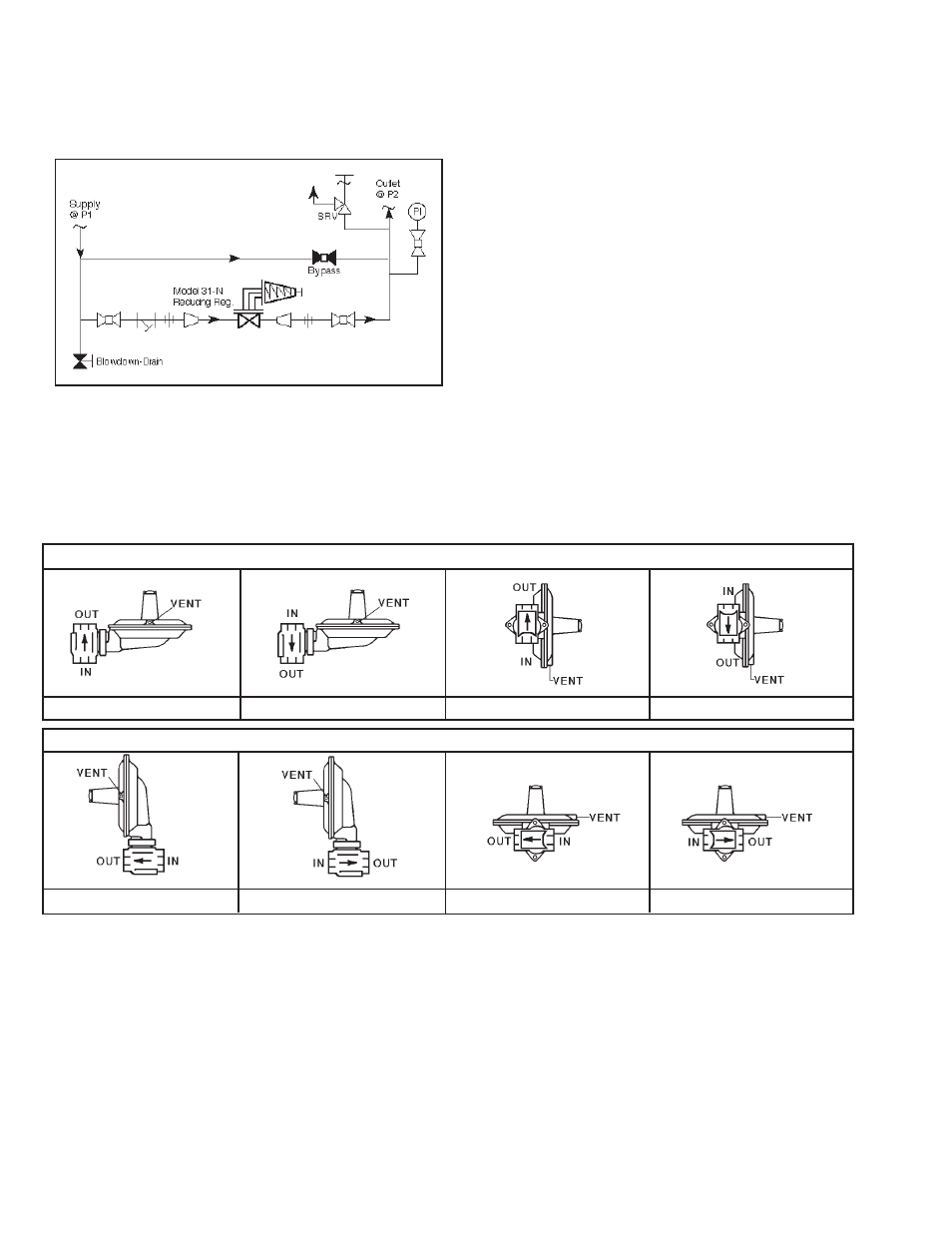

Figure 1

Recommended Piping Schematic For

Pressure Re duc ing Station

Position 1

Position 2

Position 3

Position 4

FOR VERTICAL PIPING

FOR HORIZONTAL PIPING

Position 1

Position 3

Position 2

Position 4

Figure 2

III. PRINCIPLE OF OPERATION

1. Refer to internals drawings Figures 5 thru 8.

2. Internal trim movement occurs as pressure vari a-

tions register on the diaphragm. The registering

pressure is the controlled outlet pressure, P

2

, or

down stream pressure. The range spring opposes